OVERCOMING STEAM-WAGON TROUBLES

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

More Ideas Described by Our Driver and Mechanic Readers.

sTEAM-WAGON drivers are occasionally called upon to deal with a peculiar and special difficulty which is rarely encountered by the man who has only to do with petrol machines. He has the trouble which ensues when a joint goes. On a steam wagon, particularly an overtype machine, there is a number of steam-tight joints which are usually made with Hallite or a similar material : sometimes they are made with asbestos string and white or red lead mixture. At any rate, no matter 'how they may be made, there are enough of them to increase the chances of trouble far and away in advance of those of the same kind likely to be met with where the only joint is that betvee..n the cylinder head and the main casting, which is all that the petrol driver has to bother about. When a steam joint goes on the engine, nothing more can be done until it is repaired, and there are not a few drivers who e (mid welcome hints as to how a temporary repair to sueh joints can be effected. POT that reason, we aevard the

15s. prize this week to " of Frampton-on-Severe, for his story of bow he carried out such a repair, The second letter on the same subject, from, curiously enough, a Man of the same surname, and almost the same initials, " W.H.C.," runs it very close.

" W.M.C." drives a Sentinel, an which, on a recent occasion, the rear cylinder joint blew out. This, he reminds us, is a most unusual occurrence, and, for that reason a spare joint was Tait in stock. Now, had the joint which failed been a front one, there would have been very little difficulty in replacing it, and this letter would net have been written. In the case of a front joint, there is nothing in the way of removing the cover and making a new joint, by the simple process of hammering a piece of jointing material on to the cylinder face. To do this in the case of a rear joint would have involved the remeval of the pistons, and their dismantlement from the trunk guides, which was out of the question. SOMB sort of a jeint had to be devised which could be made without this procedure, and the description of how this was accomplished is of interest.

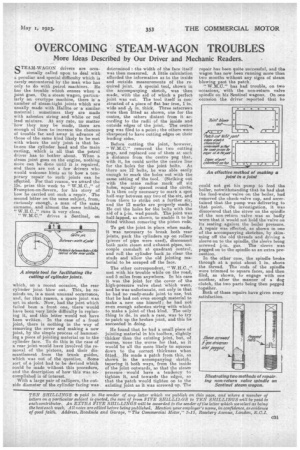

With a large pair of callipers, the outside diameter of the cylinder facing was

determined : the width of the face itself was then measured. A little calculation afforded the information as to the inside and outside measurements of the required joint. A special tool, shown in the accompanying sketch, was then made, with the aid of which a perfect joint was cut. The tool itself is constructed of a piece of fiat bar iron, 1 in, i

wide and n. thick. Three setscrews were then fitted as &hewn, one for the centre, the others distant from it according to the radii of the inside and outside edges of the joint. The centre peg was filed to a point; the others were sharpened to have cutting edges on their leading sides.

Before cutting the joint, however, " W.M.C." removed the two cutting pegs, and replaced one of thete at such a distance from the centre peg that, with it, be could scribe the centre line for the holes for the joint bolts. As there are 12 bolts, he was able easily enough to mark the holes out with the same setting of the tool. (Striking out with the same radius mark off six holes, equally spaced round the circle.. It is then only necessary to mark a spot half-way between any two of the six, and from there to strike out a further six, and the 12 marks are properly made.) He cut the holes for the bolts with the aid of a L-in. wad punch. The joint was half-lapped, as shown, to enable it to he fitted without removing the piston rods.

To get the joint in place when made, it was necessary to break both rear joints, pack the cylinders up on rollers (pieces of pipe were used), disconnect both main steam and exhaust pipes, uncouple camshaft at quadrant control, and roll the cylinder back to clear the studs and allow the old jointing material to be scraped off the face.

The ether correspondent, " W.H.C.," met withhis trouble while DR the road, and 5 miles from anywhere. In his case it was the joint for the cover of the high-pressure valve chest which went, and he was unfortunate, not only in that he had no ready-anade joint to use, but that he had not even enough material to make a new one himself ; he had not even enough asbestos string with which to make a joint of that kind. The only thing to do, in such a case, was to try to patch up the broken joint, and this he succeeded in doing.

He found that he had h small piece of jointing material in his toolbox, slightly thicker than the existing joint, but, of course, none the worse foe that, as it would be all the more likely to squeeze down to the correct thickness when fitted. He made a patch from this, as shown in the accompanying sketch, tapering it both ways, from the inside of the joint outwards, SD that the steam pressure would have a tendency to tighten it, and towards the edges, so that the patch would tighten on to the existing joint as it was screwed up. The

repair has been quite successful, and the wagon has now been running more than two months without any signs of steam blowing past the patch, "W.M.C." has had trouble on two occasions, with the Don-return valve spindle on his Sentinel wagons. On one occasion the driver reported that he

could not get his pump to feed the boiler, notwithstanding that he had shut the feed-water valve on the boiler, had removed the check-valve cap, and ascertained that the pump was delivering to that point. On investigation it was discovered that the screw on the spindle of the non-return valve was se badly worn that it would not hold the valve on its seating against the boiler pressure. A repair was effected, as shown in one of the accompanying sketches, by skimming off the old threads and (hiving a sleeve on to the spindle the sleeve being screwed 1-in. gas. The sleeve was pegged on to the spindle as an extra pree caution..

In the other case, the spindle broke through at a point about 1 in. above the thread. The ends of the spindle were trimmed to square faces, and then filed, as shown, to engage with one another, after the manner of a dog clutch, the two parts being then pegged together.

Both of these repairs have given every satisfaction.