HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

366.—Improving the Petrol Tank Strainer of the Karrier.

The K4-type Karrier has a strainer of substantial desagp fitted in the filling orifice of the petrol tank. The strainer is very efficient, but, owing to the restricted passage through which the petrol has to flow,

refilling the tank is necessarily a somewhat slow process.

The gauze forming the filtering medium is built up in the usual cylindrical form, but is protected both inside and out by being fitted between sheet metal casings, as shown in some of the sketches which we reproduce. The slight difference in the respective diameters of the three parts causes the restriction to which we have already referred, as, owing to the differing positions of the vent holes in the inner and outee protectors, the petrol has to pass down the confined annular space between them while on its way to join the main body of fuel in the tank. Considerable improvement may be effected if 12 1-in. holes are drilled through the bottom cap of the central casing, as a more direct path through the lower portions of the three cylindrical members is then available for the spirit.

A further advantage can be gained by enlarging the opening through the air-vent plug, which will be found at the opposite end of the tank. The bore of the vertical hole in the plug should be increased to i-in diameter to within in. of the top, and an additional k-in hole drilled into this central enlargement through each flat of the hexagon.

367.—Valve Tappet Adjustment on Dennis Engines.

The revised setting for the tappets on all Dennis 105 mm., 10 mm. and 115 mm. bore engines made since 1914, is .006 in. for the inlet tappet and .010 in. for the exhaust, the adjustments to be made when the engine is at its normal temperature. It is also advisable to bring each cylinder respectively to its compression stroke in order to ensure that the clearance is correct.

368.—A Repair to a Magneto Armature.

After a magneto has been running for some considerable time the insulation protecting the wire leading into the collector ring sometimes becomes perished and thus causes a short which at first is only occasiona,!, but gradually increases as the insulation continues to burn away, until, finally, it causes the engine to stop, in which case, the usual practice is to send the armature away to be rewound.

Where the trouble has been caused in the manner stated, a good repair can, however, he made in the following way, effecting a saving in both time and expense.

First, draw off the ball race from, the armature and then remove the collector ring. Now take out the spindle and easy access can he obtained to the damaged parts. Cut away the burnt insulation until the wire 3s exposed. This also will usually be found to be burnt. If so. cut off the bad part and solder to the good end a fresh piece of .wire of the same gauge and of the necessary length. Now, over this wire and the remaining portion of the insulation slip a piece of bicycle valve tubing, which should be pushed well. homa. Bind this tubing tightly with thread, and over the whole paint a thick coat of shellac.

If thought necessary, a narrow piece of insurating tape may also be: bound round and varnished, and the whole will make a good and lasting repair.

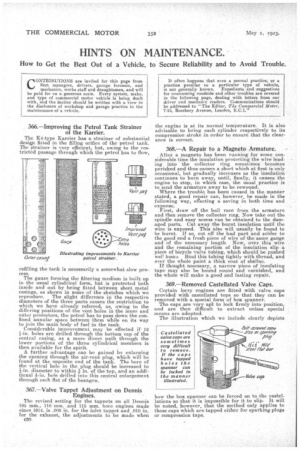

369.--Removed Castellated Valve Caps.

Certain lorry engines are fitted with valve caps provided with castellated tops so that they can be removed with a special form of bon spanner.

The caps. are vary ap't to lock firmly into position, and are then difficult to extract unless special means are adopted.

The illustration which we include clearly depicts

how the box spanner can be forced on to the castellations so that it is impossible for it to slip. It will be noted, however, that the method only applies to those caps which are tapped either for sparking plugs or compression taps.