RUNNING FROM POLE POSITION

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

ler receiving a mmendation last year, yland's Roadrunner has Ine on to win a Design )uncil Award. 7companying it among e honours this year is a ulti-function pole erector , King Trailers

• AST year. Leyland's Roadrunner got a special commendation in the —"Design Council Awards: this year, las walked off with one of only three ards in the motor industry section.

le other two are for the King Trailers 650 pole erection unit, and the .tomotive Products Borg & Beck tch used in single-seater racing cars.) The virtues of Leyland's 7.5-tonner ire become well-known since the lick first two-wheeled its way across nation's television screens 18 months a. The Design Council has summed up thus: "The company has viously paid a lot of attention to sign and ergonomic needs, and oduced an exceptionally well-thoughtt design. The ease-of-drive features t Roadrunner in a class of its own for e small delivery vehicle and self-drive re market."

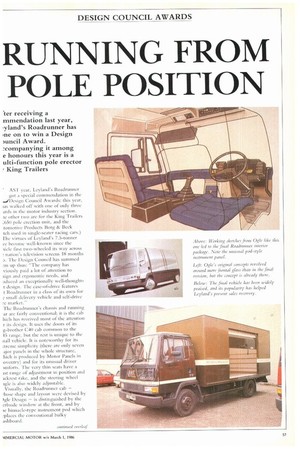

The Roadrunner's chassis and running 'ar are fairly conventional; it is the cab Inch has received most of the attention r its design. It uses the doors of its g-brother C40 cab common to the 45 range, but the rest is unique to the nal] vehicle. It is noteworthy for its areme simplicity (there are only seven .ajor panels in the whole structure, hich is produced by Motor Panels in oventry) and for its unusual driver =forts. The very thin seats have a 1st range of adjustment in position and ackrest rake, and the steering wheel igle is also widely adjustable.

Visually, the Roadrunner cab — 'hose shape and layout were devised by )gle Design — is distinguished by the erbside window at the front, and by ic binnacle-type instrument pod which iplaces the conventional bulky

ashboard.

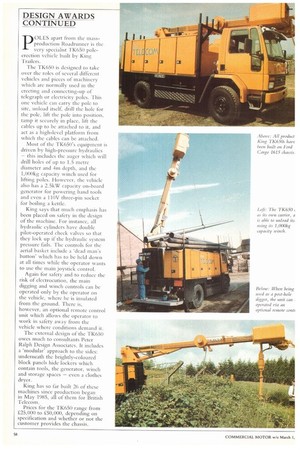

pOLES apart from the massproduction Roadrunner is the very specialist TK650 poleerection vehicle built by King Trailers.

The TK650 is designed to take over the roles of several different vehicles and pieces of machinery which are normally used in the erecting and connecting-up of telegraph or electricity poles. This one vehicle can carry the pole to site, unload itself, drill the hole for the pole, lift the pole into position, tamp it securely in place, lift the cables up to be attached to it, and act as a high-level platform from which the cables can be attached.

Most of the TK650's equipment is driven by high-pressure hydraulics — this includes the auger which will drill holes of up to 1.5 metre diameter and 4m depth, and the 1,000kg capacity winch used for lifting poles. However, the vehicle also has a 2.5k W capacity on-board generator for powering hand tools and even a 110V three-pin socket for boiling a kettle.

King says that much emphasis has been placed on safety in the design of the machine. For instance, all hydraulic cylinders have double pilot-operated check valves so that they lock up if the hydraulic system pressure fails. The controls for the aerial basket include a 'dead man's button' which has to be held down at all times while the operator wants to use the main joystick control.

Again for safety and to reduce the risk of electrocution, the main digging and winch controls can be operated only by the operator on the vehicle, where he is insulated from the ground. There is, however, an optional remote control unit which allows the operator to work in safety away from the vehicle where conditions demand it.

The external design of the TK650 owes much to consultants Peter Ralph Design Associates. It includes a 'modular' approach to the sides: underneath the brightly-coloured block panels hide lockers which contain tools, the generator, winch and storage spaces — even a clothes dryer.

King has so far built 26 of these machines since production began in May 1985, all of them for British Telecom.

Prices for the TK650 range from £25,000 to £50,000, depending on specification and whether or not the customer provides the chassis.