The ART of LOADING

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

SAFE loading requires experience: securing and sheeting-up demand a degree of forethought and skill not possessed by every driver. It is not difficult to identify lorries on which the loads are poorly secured, but there are many which illustrate the right way of doing the job.

Loads fall broadly into three categories—soft and compressible, combined hard and soft at different heights, and hard.

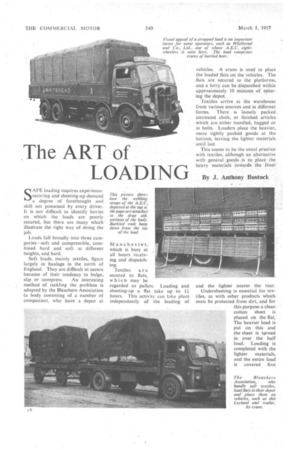

Soft loads, mainly textiles, figure largely in haulage in the north of England. They are difficult to secure because of their tendency to bulge, slip or compress. An interesting method of tackling the problem is adopted by the Bleachers Association (a body consisting of a number of companies), who have a depot at Manchester, which is busy at all hours rezeiving and dispatching.

Textiles a r e secured to flats, which may be regarded as pallets. Loading and sheeting-up a flat take up .to 1+ hours. This activity can take place independently of the loading of

vehicles. A crane is used to place the loaded flats on the vehicles. The flats are secured to the platforms, and a lorry can be dispatched within approximately 10 rininutes of entering the depot.

Textiles arrive at the warehouse from various sources and in different forms. There is loosely packed untreated cloth, or finished articles which are either bundled, bagged or in bolts. Loaders place the heavier, more tightly packed goods at• the bottom, leaving the lighter materials until last.

This seems to be the usual practice with textiles, although an alternative with general . goods is to place the heavy materials towards the front and the lighter nearer the rear. lindersheeting is essential for tex

tiles, as with other products which must be protected from dirt, and for this purpose a clean cotton sheet is placed on the flat;

The heavier load is put on this and the sheet is tprned in over the half load. Loading is completed with the lighter materials, and the entire load is covered first with a waterproof cotton sheet, and then with an oilsheet.

In general, ropes are secured by the use of garden ropehooks, but some operators prefer the ratchet rollers with which, it is claimed, a much greater pull can be exerted to co.npress the light cloth, without fear of damaging the ropes themselves.

Have ropes had their day? Many of the larger operators are adopting the practice of strapping loads to their vehicles. There are a few companies which use nothing but webbing straps and belts, and others who employ ropes or straps according to their application to specific jobs,Sometimes both are used for the same load. •

Matter of Cost

This subject of straps is interesting. Too many operators dismiss the matter with the remark that straps are expensive—and that is that!

Undoubtedly, the initial expense is greater, but is it less economical in the long run? It seems unlikely. A good-quality webbing strap will probably outlast a succession of ropes. Straps are likely to do less damage to loads,containers and sheets. They can be secured more firmly than ropes and allow less movement of the load. Finally—a point that matters to some operators—straps have a greater visual appeal. ---.

Small and Parkes, Ltd., Hendham Vale Works, Manchester, 9, manufacture vehicle straps for both private and commercial use. Better known as the manufacturers of Don brake and clutch facings, they have had much experience in the production of woven materials, such as machine belting.

It is only recently,. encouraged by . requests from a number of commercial-vehicle operators, that Small and Parkes started production of retaining straps for vehicle loads. Each three-ply, 2-in, white webbing Roko strap, made 'ofcotton, will withstand a 3,000-1b. strain. This allows a high safety factor, far in excess of that associated with most lorry ropes. The straps dre secured to the vehicle by stout hooks attached to This LR.i.o, 11w its Roaa Services, Ltd., has a plastics sheet over its load. The company are trying p.v.c. impregnated and p.v.c. sprayed types of sheet. Varied loads are handled and both ropes and straps are used for tying shackles built into the body. The free end of the -shorter of the two straps in each pair has a wide buckle, whilst the end of the longer strap has a reinforced tongue.

Pursuing the subject of loads that are strapped rather than roped, and further to study the effectiveness of Roko straps, a visit was arranged to Whitbread's bottling plant at Ashtonunder-Lyne. In common with most brewers, Whitbread take a particular pride in the turnout of their fleet.

In company with Mr. E. C. Calthorpe, plant manager at Ashton, I inspected a number of their vehicles. Each was spotless.

Extreme Care

The first out of the loading bay after our arrival was an A.E.C.

Mammoth. It had been loaded and sheeted-Up with the extreme care necessary when bottled beer is carried. The platform was slightly concave so that the crates were stabilized by leaning towards the centre. This particular vehicle was carrying 1,444 crates each holding a dozen bottles—a total of almost 15 tons.

The crates were carried 17 •to the row l eight wide, and nine high, with a 10th row over the middle which gave a tapered sheeting outline to spill rain water, and to increase inward pressure at the top. Strengtheners were placed On the outer • edges of• the crates to be beneath the straps, and the load was sheeted-up and strapped in about half an hour.

Whitbread take no chances with their beer, and they have proved to their own satisfaction that straps are the safest, easiest and most efficient method of securing crates.

Operators who carry loads of a constant size and shape experience little difficulty once they have arrived at the correct solution to their own particular problem, but what of the general carrier?

He is faced with the perpetual difficulty of ensuring that each load carried by every one of his vehicles Ls correctly secured. He has to rely upon the ability and common sense of his drivers, and thus it is incumbent upon him to engage men who have a sound understanding of their jobs.

Mr. J. T. Price, of Harris Road Services, Ltd., Lostock, Graham, Northwich, Cheshire, invited me to visit their depot and investigate the

subject of varied loads. The first vehicle inspected was a good example of the kind of varied load that a general haulier handles. It consisted of bags of salt, a number of empty crates and a few dozen pallets.

Skilled Man

The driver—a man of long experience, who manages to sheet up a half-height full-length load in 10 minutes—had placed the salt bags towards the front of the platform, leaving room for the empties and a number of pallets at the rear. These were sheeted-up, first with an impregnated cotton sheet, then with a p.v.c. impregnated sheet. The remainder of the pallets were placed on top, unsheeted, but secured with 12-in. straps which could not damage the pallets.

Harris Road Services use both ropes and straps, depending upciti the kind of load carried: As art example, a Leyland Octopus was being loaded with 50 drums of caustic soda from the ICJ. works and, in addition, an end-load of paper bags.

As a rule it is undesirable to sheet up soda drums because of the radiation heat of the caustic, but on this occasion the entire load had to be sheeted in order to protect the paper bags.

First, the drums were skotched 'and roped, the load was sheeted and finally ropes were passed over the part of the sheet covering the drums. Webbing straps • 12-in, wide were used to secure the sheet over the bags.

Mr. Price remarked that his •company were carrying out experiments with two different kinds of top sheet

ing—one p.v.c. impregnated, the other p.v.c. sprayed. The latter is much the better in appearance, and it more successfully carries advertising matter on the surface, but it is too early to estimate the comparative efficiency of the two.

There appears little to gain in time by using straps. The benefits are greater load security' and better care of customers' goods.

Sheeting-up depends to a great extent upon the kind of load to be carried. One of the most awkward is Alkathene, a waxy substance used in the plastics industry. It may take more than II hours to do the job properly, and even then there is the possibility of the load shifting. Airtight paper bags are difficult to secure, but the matter of carrying tyres should be mentioned only in a whisper. It has been said that even trawler nets are ineffective.