• THE NEED FOR EFFECTIVE BRAKES.

Page 9

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

In .View of the Rapid Approach of the Motor Coach Season, this Article, on a Subject Vital to the Welfare of the Industry, Should be Read by Manufacturers and Coach Owners.

The article is written at eur special request by an authority who,. during the war, had charge of

M.T. vehicles in unusually difficult country. •

IN THE first portion of this article, which appeared in the last issue of Tg Commercial Motor, I concluded my opening remarks by setting out the six objects in the design of brakes. Because of the break in the article, I repeat them here. They are as follow : —

• (1) The brakes to be of such dirnensions that either the hand brake or the foot brake will hold the vehicle, fully loaded, on a gradient of, say, one in six.

(2) The brakes should' continue to function in an efficient manner for the whble char-a-banes season without other adjustments than those that'can be effected easily by the driver v. ith a couple of spanners.

(3) When replacements are required, it should be possible to effect them in the shortest possible time.

(4) The condition of the brakes should be capable of being readily seen.

(6) The brakes should be capable of being held hard on for two or three miles on a steep hill with a full load without damage due to overheating. Where two brakes are not sufficient for this requirement to be complied with, three should be fitted, (6) Neither brake should be dependent for it s action upon such comparatively delicate -parts as differential pinions. The fulfilment of all the foregoing requirements should not present insurmountable difficulties, yet I know of no vehicle that fulfils them. Most vehicles, perhaps, fulfil number one requirement and a few numbers four and six, but, as to the rest of the demands, very little attempt appears to have been made to meet: them.

For the time being object number one may be considered as an accomplished fact.

Point 2.—Longevity of Wearing Surfaces.

My chief complaint concerns the 'second objective. The' thickness of the average brake shoe lining is about in., -but, owing to the peculiar motion of all internal-expanding shoe-brake, only, about threequarters of the whole of the material can actually be used; the lining being worn through at or about the centre of the shoe, while at the ends it may only wear

to half its original thickness. .

For a char-a-banes to run a season, the lining ought to be at least 1 in. thick, while the expanding cam must give the shoes a travel eorresponding with the increased thickness of the lining. The cam, moreover, should effect the total expansion with a rotary motion .not exceeding SO degrees, "otherwise some other adjustment than that to the rod attached to the cam lever must !be used, which addition is likely to complicate the process and to fog the driver. I also consider that thereW should be some very obvious indication alongside the canelever to correspond with the. maximum permissible wear.of the brake lining, in order that the driver may not continue his adjustment beyond a certain:point, ignorant of the fact that the lining is worn through. This is recommended not so much to combat the objection of wearing the shoe away, as the danger of the cam turning over its dead centre. Morel than one accident has occurred from this cause, and a stop should be fitted to prevent it happening.

Points 3 and 4.—Visability, Accessibility and Replacement.

I do not know if manufacturers cherish an erroneous idea that the brakes of their vehicles never need attention, but one might be well excused for thinking so. I have in mind one particular footbrake which needed relining regularly once a month. The brake is at the back of the gearbox; in front of the shoes is an immovable cover, while totally encasing the rear face Of the shoes and the.periphery is the brake drum. With this form of construction, it

was utterly impossible to see the condition of the shoes ; one could only guess their condition by the poSition of the expanding lever. The worst feature-of this brake, however, does not reveal itself until replacernentst are Rnecessary, when the discovery is made that, in order to remove the brake drum to reach thelshoes, the eardan-shaft has to be dropped, Which involves disturbing both back and front universal joints. When the time comes to reassemble after the shoes have been relined, the assembly and adjusting have to be carried out absolutely in the dark and are largely guess-work. In all, it took, in my experience, two mechanics the best part of a day and a half to dismantle and reassemble this brake, the actual lining of the brake-shoes, which after all is the main object, taking at the outside two hours.

A. transmission brake, if used, should be placed on the tail end of a worm shaft ; then, provided that the shoes are not encased in a saucer-shaped drum or tucked away inside a recess,in the petrol tank, the driver can see at a glance, without crawling underneath the chassis, the condition of the brakes, and, when replacements are necessary, they can be put in with a minimum of time and expense. The foot-brake of the A.-Ce light car and the La Buire are paragons in this respect ; in the latter vehicle, in which the final drive is by bevel, a separate bevel-driven shaft extends rearwards to carry the brake drum. This construction 'involves extra expense, but I consider it justified. In the matter of side brakes, the complaint is not that they cannot be seen but that, having ascertained that the shoes need relining, they are so difficult of access. To get at the brake-shoes it is invariably _ necessary to remove the wheel, and, as the rear wheel of almost any lorry weighs from 5 cwt. to 6 cwt., a single-handed driver is not going to take one off more often than is absolutely necessary, while the proprietor is naturally loathe to hold up the vehicle for three or four days or more for the work to be done.

• It is not a case of just taking the wheel off and putting it on again ;• the chances are that the wheel will have to be taken on and off half-a-dozen times in the process of adjusting the new linings, easing off the high places, etc.

• Where a fleet of vehicles is concerned, the importance of accessibility is not ea great. It pays to buy suitable tackle, and one or two men can specialize in brake work and cut times down to a fraction of what it costs the proprietor of a single vehicle, who is not justified in buying expensive tackle and has only the driver and perhaps, one other unskilled man to I do the work. t appears to me to be quite within the bounds of possibility to design the side brakes so that the shoes may be taken out for relining and replaced without disturbing the wheel.

Point 5.--:Cooling.

For char-A-banes required to tour in the Lake District, certain parts of Devonshire, and in other hilly areas, provision must be made to keep the brakes from overheating. A water drip, fed by gravity from a tank having a tap within easy reach of the driver, is quite inexpensive and effective. Not more than two g allons of water need be carried, but the brake drum must have a side flange to retain the water, which, by centrifugal farce, will spread itself over the inside face of the drum. This construction precludes the use of internal expanding brakes, but, as this form of brake is of very doubtful virtue, no importanee is attached to its abolition. Drums with radiating fins are quite useless for heavy vehicles and only get clogged with mud.

Point 6.—The Transmission Brake.

The proviso that no delicate parts shall form an essential feature of the braking system rules out the transmission brake, which relies on the axle shafts, differential pinions and right •angle drive for its action. Almost every live-axle vehicle with which I have had dealings has suffered from weakness in, at least, one of these parts, and, if any one of them fails, the brake is useless ; on the other hand, I have never yet driven a lorry, or even a ear, which had an effective foot-operated brake acting direct on the back wheels. • The reason for this is not difficult to see, With a hand lever, it is quite easy to exert a pressure of 100 lb. through a distance of 18 ins. This

08 movement need not give a brake-shoe movement more than in., so that the pressure applied to the brake 18 shoe can be as high as 100 x — total 14,400 lb. As suming that the same weight can be applied to the pedal, which is very doubtful, the movement cannot be more than a third of that distance, so that the maximum pressure is reduced proportionately to approximately 4,800 lb., which is insufficient to be effective. Pedal pressure is effective in the case of the cardari-shaft brake, because the peripheral speed of the drum may be front four to eight times that of the road wheel drum.

Having established the fact that 4,800 lb. or whatever it happens to be, is insufficient, and that the human element has been already taxed to the limit, the question arises as to whether the ordinary internal-expanding brake makes the most use of the power available. I do not propose. to answer that question' but, rather, to beard the brake-shoe in its drum and leave the reader to draw his own conclusions.

The Internal-expanding Shoe Brake.

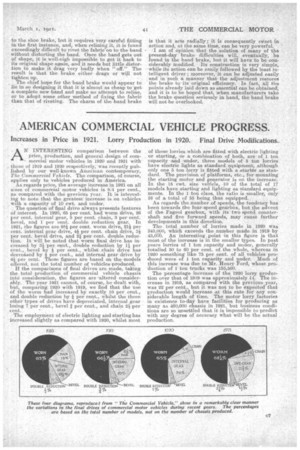

Fig. 1 is a diagrammatic illustration of a typical internal-expanding shoe brake. The shoe is pivoted at P and is forced against the inside of the drum by the cam (C). If four points be taken in the fabric and their movements in relation to the brake drum be a,nalyeed, it will be seen the motion is not in the least radial. At point No. 1 the motion is most nearly radial, and it gradually gets less until, at the point No. 4, it is almost tangential. _Whether thisis a good or bad feature is difficult to say, for it will be seen that, as the moments above the pivot (P) decrease, the wedging action increases, the one action compensating the ether to some extent.

The next point of interest lies in an analysis of the motion of the drum in relation to the shoes. If the drum be imagined as revolving in the direction of the arrow, we find that the drum rubbing against the shoe tends to drag the shoe in the same direction which, in this particular instance, is against the action of the cam_ In other words this dragging action, which is the sole reason for the existence of the brake, tends to nullify itself. In the case of the other shoe (not shown) the action is reversed. The drag of the drum on this shoe tends to wedge the shoe further in engagement. It is probably for this reason that one shoe almost always wears more than the other. From this consideration of the action of an internalexpanding brake, innumerable deductions might be drawn but, without actual tests, it would be exceedingly iliffieult to prove the deductions as being correct. One --fact, however, that stands out preeminent is that the internal-expanding brake is by no means balanced and cannot claim sympathy on that score.

Fig. 2 shows the manner in which the shoe lining wears.. The greatest wear takes place at or about the point (B), and, when the lining is worn through at this point, it is still at least half its original thickness at the points (A) and (D). In other words, little more than three-quarters of the avalable lining can be worn away, and we have the anomaly that the wear is greatest where the pressure is least. Fig. 2 also brings to light, the distressing feature that, to get just a normal clearance for the shoes when in the 'off ".• position at A and I) of in., there will be a clearance of at least in. at B. This clearance at B will absorb at least in. of cam travel, which is half the total travel given by many cams. In these circumstances, it is not surprising that the average brake rear requires constant adjusting and replacements in order to keep it in reasonably good fettle.

• The Band Brake.

One or two firms have still remained faithful to the externalesontracting band brake, and, when new, there is no doubt that this form of brake is superior

to the shoe brake, but it requires very careful fitting in the first instance, and, when relining it, it is found exceedingly difficult to rivet the fabrie'on to the band without distorting the band. Once the band gets out of shape, it is well-nigh impossible to get it back to its original shape again, and it needs but little distortion to make it drag very badly when "off." The result is that the brake either drags or will not tighten up. The chief hope for the band brake would appear to lie in so designing it that it is almost as cheap to get a complete new band and make no attempt to reline, or to adopt some other method of fixing the fabric than that of riveting. The charm of the band brake is that it acts radially; it is consequently sweet in action and, at the same time, can be very powerful. am of opinion that the solution Of many of the present-day brake difficulties will, eventually, befound in the band brake, but it will have to be-considerably modified. Its construction is very simple, 'while its action can be easily followed by the least intelligent driver ; moreover, it arm be adjusted easily and in such a manner that the adjustment rebstores the brake to' its original efficiency. In fact, all the points already laid -down as essential can be obtained; and -it is to be hoped that, when manufacturers take the brake question seriously in hand, the band brake will not be overlooked.