Electric Drive in Garage and Workshop.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

VI.---The Generation of Electricity.

In the first article of this series some remarks were made regarding the supply of electric current, and although it was stated that in some eases—where a supply company's mains were not available— it might be necessary to geeerate current on the spot, the matter was not discussed in detail. Viany important garages and workshops, however, are situated far away from a corporation's supply mains, and it becomes necessary for these establishments, in order to reap the many advantages of the various applications of electricity in the garage, to generate their own current. This involves the use of a prime mover and an electric generator, the function of the former being to drive the generator, and to •generate electricity whier •can be applied, as already pointed out in former articles, to all manner of uses.

The Prime Mover.

The prime mover or driving engine can be of any suitable character. It may take the form of a gas engine, oil engine, petrol engine, steam engine, steam tin.bine, water turbine,etc. For the purpose of driving i an electric dynamo n a garage, however, the internal-combustion engine will be found to be the most suitable driving medium, in the great majority of eases. This may be either a gas, oil or petrol engine. The steam engine and the steam turbine can be ruled out in this connection, as in each case additional plant for the generation of. steam is required ; water power cannot generally be obtained with advantage in this country.

The Gas Engine.

In many cases a public supply' of electricity is not obtainable, but it is often found that a supply of gas is available. • In such a ease, where it has been decided to utilize a gas-engine drive, it becomes unnecessary to go to further expense and install producer gas plant for generating the gas fuel. Instead, the public supply mains can be brought to the engine. This is quite an economical proposition, too, as the following figures will show :— Take, for example, town gas at an average cost of 2s. 6d. per 1000 cubic ft., and assuming the gas engine to be working on a three-quarter load. Under these conditions the gas consumption may be with safety reckoned at 20 cubic ft. per brake-horse-power. The cost of town gas would then be as follows:—

Per brake h.p. hour ... ... .6 of a penny. Per unit of electricity (kilowatthour) .98 „ „

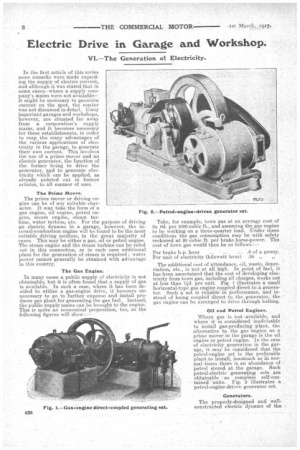

The additional cost of attendance, oil, waste, depreciation, etc., is not at all high. In point of fact; it has been ascertained that the cost of developing electricity from town gas, including all charges, works out at less than 11d. per unit. Fig. r illustrates a small horizontal-type gas engine coupled direct to a generator. Such a set is reliable in performance, and instead of being coupled direct to the generator, the gas engine can be arranged to drive through belting.

Oil and Petrol Engines.

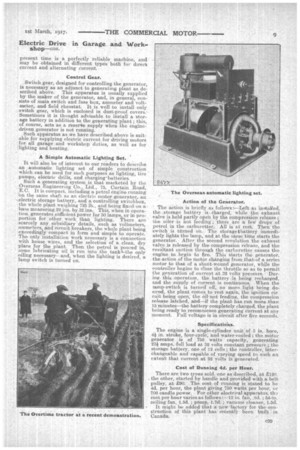

Where gas is not available, and where it is considered inadvisable to install gas-producing plant, the alternative to the gas engine as a prime mover in the garage is the oil engine or petrol engine. In the case of electricity generation in the garage, it may be considered that the petrol-engine set is the preferable plant to install, inasmuch as in normal times there is an abundance of petrol stored at the garage. Such petrol-electric generating sets are obtainable as complete self-contained units. Fig. 2 illustrates a petrol-engine-driven generator set.

Generators.

The properly-designed and wellconstructed electric dynamo of the present time is a perfectly reliable machine, and may be obtained in different types both for direct current and alternating current.

Control Gear.

. Switch, gear, designed for controlling the generator, is necessary as an adjunct to generating plant as described above. This apparatus is usually supplied . by the maker of the generator, and, in general, consists of main switch and fuse box, ammeter and voltmeter, and field rheostat. It is well to install only . switch gear, which is enclosed in dust-Proof covers.Sometimes it is thought advisable to install a storage battery in addition to the generating plant; this, of course, acts as a reserve supply when the engine. driven generator is not running.

Such apparatus as we have described, above is suitable for supplying electric current for driving motors for all garage and workshop duties, as well as for ;lighting and heating.

A Simple Automatic Lighting Set.

It will also be of interest to our readers to des' cribe an automatic lighting set of simple . construction which can be used for such purposes as lighting, tire . pumps, electric drills, and charging'hatteries,

. Such a generating system is that marketed by the . Overseas .Engineerin. Co„ Ltd., 75, Curtain Road, E.C. It is compact, including a petrol engine. running on the same shaft as an electric motor .generator, an ',electric storage battery, and &controlling switchbox, the whole plant weighing 725 lb., and being fixedon a • base measuring 22 ins. by.32 ins This, when in operation, generates Sufficient power for 30 lamps, or in proportion for other work than lighting. There. are scarcely any subsidiary details, such as voltmeters, ammeters, and circuit breakers, the whole plant being exceedingly compact in form and simple to operate. The only installation work necessary is a connection with house wires, and the selection of a clean, dry place for the .plant. Then the petrol is poured. in, some lubricating oil is run into the tank--the only .oiling necessary—and, when the lighting is desired, a lamp switch is turned on. The action is briefly as follows :—Left as installed, the storage battery is charged, while the exhaust .valve is held partly open by the compression release ; the oiler is not feeding ; there are a feud drops of .petrol in the carburetter. All is at rest. Then the switch is timed on. The storagethattery immediately lights the. lamp, and at the sa,melirne starts the generator. After the second revolution the exhaust valve is released by the. compression release, and the resultant suction through the carburetter causes the engine to. begin to fire. This starts the generator, the action of the motor changing from thabof a series motor to that of a shunt-wound generator, while the controller begins to clime the throttle so as to permit the generation of current at 32 volts pressure. .During this operation, thebattery is being recharged, and the supply of current is continuous. When the lamp-switch is turned off, no more light being desired, the plant comes to rest again, the ignition circuit being open, the oil not feeding, the compression release latched, and—if the plant has run more than 15 minutes—the battery completely charged, the plant being ready to recommence generating current at any moment. Full voltage is in circuit after five seconds.

Specifications.

The engine is a single-cylinder unit of 3 in. bore, 44 in. stroke, four-cycle, and water-cooled ; the motor generator is of 750 watts capacity, generating 23i amps. full load at 32 volts constant pressure ; the storage battery, one of 12 cells ; the controller, interchangeable and capable of varying speed to such an extent that current at 32 volts is generated.

Cost of Punning 4d. per Hour.

There are two types sold, one as described, at £120, the other, started by handle and provided with a belt pulley, at £90. The cost of running is stated to be 4d. per hour, the plant giving 750 watts per hour, or 700 candle power. For other electrical apparatus; the cost per hour varies as follows :-12 in_ fan, .8d. ; ceiling fan, 1.5d. • pump, 1.7d. ; vacuum cleaner, 1.5d. It might be added that a new factory for the con-. struction of this plant has recently been built in

Canada. •