THE DESIGN OF TRACTOR WHEELS.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

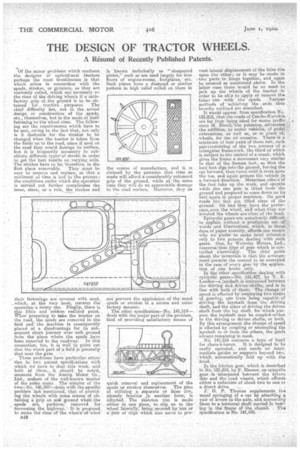

the minor problem's which confront the designer of agricultural tractors perhaps the most troublesome is that which arises in connection– with the spuds, strakes, or grouters, as they are variously called, which are :necessary on the rims Of the driving 'wheels if a satisfactory grip of the ground is to be obtained for tractive purposes. The chief difficulty lies, not in the actual design or construction of the .eputs etc., themselves, but in the mode of their fastening to the wheel rims. The following are the reqeirements which have to be met, .owing to the fact that, :not only is it desirable for the Strokes to be changed when the tractor is taken from the fields-on to the road, since if used on the road they would damage its surface, but it is frequently necessary to substitute different types'of strake. in order to get' the best results on.yarying soils. The strokes have to be, 'therefore, in the

first place removable. They must be easy to remove and replace, so that a minirmini of time is lost in the prOcess; the conditions under which the operation is carried out further complicates the issue, since; as a rule, the strokes and

their fastenings are covered with mud, __which, at the very least, renders the operation a messy one. Finally, there is this little and seldom realized point. -r'nen preparing to take the tractor on the road, the spuds are removed in the field and the machine is consequently placed at a disadvantage for its subsequent short journey over soft ground from the place where the spuds. have been removed to the roadway. in this connection, too, it is well to point out that the worst part of a field in generally that near the gate.

These problems have particular atten-: tion in two patent specifications with which we' have to deal this week, and both of them,, it shoulrl be noted, emanate from the Austin, Motor Co., Ltd., makers of the well-known tractor of the same name. The simpler of the two—No. 141,491—deals with the specific problem last mentioned, that of providing the wheels with some means of obtaining a grip on soft ground when the spuds are, perforce,' removed for traversing the highway. It is proposed to make the rims of the wheels of what •

B42 is known technically as "chequered plates," such as are used largely for iron floors of engine-rooms, footplates, etc. Such plates have a diainond or similar pattern in high relief rolled on them in the course of manufacture, and it is claimed by the patentee that rims so made will afford a considerably enhanced grip of the ground, while at the same time they will do no appreciable damage to the road surface. Moreover, they de not prevent the application of the usual spuds or strakes m a secure and satis. factory manner.

The other specification—No. 141,519-deals with the major part of the problem, that of providing satisfactory means of

quick removal and replacement of the spuds,or strakes themselves. The plan of utilizing a separate or false rim, already familiar in another form; is adopted. The skeleton rim is made either in one piece, to slip on to the wheel laterally, being secured by bee or a pair of clips which also serve to pre

vent lateral displacement of the false rim upon the other; or it may be made in . two parts to hinge together, and again be secured as mentioned above. In the latter .case there would be no need to jack up the wheels of the tractor M order to be able to apply or remove the false* rim with the spuds. Varicres methods of 'achieving the ends thus broadly outlined are described.

It would appear, from specification No 132,812, that the roads of Czecho-S:ovakia are far, from being ideal for motor,traffic since M. Zboriblithe patentee, advocates the addition, to motor vehicles, of pedal extremities, as well as, or in place of, wheels, for use on occasion. There is a minimum of four pairs of these feet, each pair;consisting of the two corners of a triangular framework, the third of which is subject to the control of a crank, which gives the frame a movement very similar to that of the human foot,. so that the heel first digs into the around forcing the car forward, then turns until it rests upon the toe, and again presses the vehicle in a forward direction. Meantime °the' a Of the 'feet take up the work, and oPerete while the one pair is, lifted from the ground 'and prepared to come down on its theel'again in proper Sequence. On good roads the feet are lifted clear of the ground. On bad they have the preference, over the wheel; and when they are lowered the wheels aro clear of the road. .

Epicyclic gears-are notoriously difficult to explain . without a, prodigious use words and illustrations, .which, in these.' days days of paper scarcity, affords one reason • why we prefer to make, brief reference only to two patents :dealing with such gears. :One, by Wolseley Motors, Ltd.., concernsjhat type of gear which is controlled electrically. The chief point about the 'invention is. that the arrangement permits the control to be exercised in the case of every gear by the sipplica

tion of one brake only. • "

' In the other specification dealing with epicyclic gears—No. 141,427, by T. E. Lander—a layshaft. is interposed between the driving and driven.shafts, and is in line with both ofthem. The change of speed is 'effected by .emplOying two trains of .gearing, one train being -capable.' of driving the layshaft from the-. driving shaft; and the other of driving the driven shaft from the lay shaft, for which purpose the layshaft may be Coupledeeither to the driving or driven shafts, or both. By this arrangement the change of speed is effected by coupling or uncoupling the layshaft to or from the others, the gears always remaining in mesh.

No. 141,516 concerns a type of hodd for chars-a-banes. It is designed to be easily operated, and. needs nd intermediate guides or supports beyond two, which automatically fold up with the hood.

In the friction gear, which is described in No. 131,318, by P. kanzer, an epicyclie gear ds -interposed between the driven disc and the road wheels, which affords either a reduction of about two to one or a direct drive.

J: G. P. Thomas supplements the usual. springing of a car by attaching a, pair of levers to the axle, and connecting them to a torsional shaft carried in bearing in the' frame of the chassis. . The specification is NO. 141,436.