Two-fuel Carburetters and Fittings III.

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

An American Device, the Knox E-Konomy Carburetter, with Several Distinctive Features ; it is Sell-contained in Respect of its Heating Device.

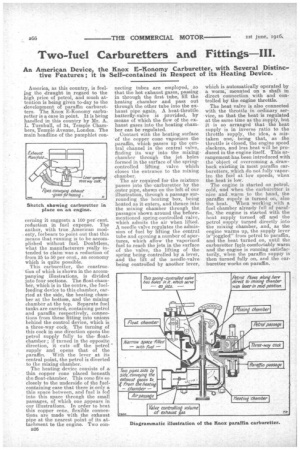

America, as this country, is feeling the draught in regard to the high price of petrol, and much attention is being given to-day to the development of paraffin carburetters. The Knox E-Konomy carburetter is a ease in point. It is being handled in this country by Mr. A. L. Turnbull, of 34, Temple Chambers, Temple Avenue, London. The main headline of the pamphlet con cerning it suggests a 100 per cent. reduction in fuel expense. The author, with true American mod. esty, forbears to point out that this means that running is to be accomplished without fuel. Doubtless, what the manufacturers really intended to claim was a reduction of from 25 to 50 per cent., an economy which is quite possible. This carburetter, the construction of which is shown in the accompanying .illustrations, is divided into four sections. The float-chamber, which is in the centre, the fuelfeeding device to this chamber, carried at the side, the heating chamber at the bottom, and the mixing chamber at the top. Separate fuel tanks are carried, containing petrol and paraffin respectively, corniceCons from these fitting into unions behind the control device, which is a three-way cock. The turning of this cock in one direction opens the petrol supply fully to the floatchamber ; if turned in the opposite direction, it cuts off the petrol supply and opens that of the paraffin. With the lever at its central point, the petrol is diverted to the mixing chamber. The heating device consists of a thin copper cone placed beneath the float-chamber. This cone fits so closely to the underside of the fuelcontaining case that there is only a thin space between, and fuel is fed into this space through the small passages, of which one appears in our illustrations. In order to heat this copper cone, flexible connections are made with the exhaust pipe at the nearest point of its attachment to the engine. Two con necting tubes are employed, no that the hot exhaust gases, passing in through the first tube, fill the heating chamber and pass out through the other tube into the exhaust pipe again. A heat-throttle butterfly-valve is provided, by menns of which the flow of the exhaust gases into the heating chamber can be regulated.

Contact with the heating surface of the copper cone vaporizes the paraffin, which passes up the central channel in the central valve, finding its way into the mixing chamber through the jet holes farmed in the surface of the springcontrolled lifting valve which closes the entrance to the mixing chamber.

The air required for the mixture passes into the carburetter by the .outer pipe, shown on the left of our illustration, through a passage surrounding the heating box, being heated as it enters, and thence into the mixing chamber through the passages shown around the beforementioned spring-controlled valve, which admits the air when lifted. A needle valve regulates the admission of fuel by lifting the central tube and opening a number of apertures, which allow the vaporized fuel to reach the jets in the surface of the valve, the lifting of the spring being controlled by a lever, and the lift of the needle-valve being controlled by another lever, which is automatically operated by a worm, mounted on a shaft in direct connection with and controlled by the engine throttle.

The heat valve is also connected with the throttle in ordinary service, so that the heat is regulated at the same time as the supply, but it is so arranged that the heat supply is in inverse ratio to the throttle supply, the idea, a mistaken one, being that, as the throttle is closed, the engine speed slackens, and less heat will be produced in the engine itself. This arrangement has. been introduced with the object of overcoming a drawback existing in most paraffin carburetters, which do not fully vaporize the fuel at low speeds, when the heat is low.

The engine is started on petrol, cold, -and when the carburetter is nice and .warm to the hand, the paraffin supply is turned on, also the heat. When working with a fuel chamber already full of paraffin, the engine is started with the heat supply turned off and the petrol supply turned directly into the mixing chamber, and, as the engine warms up, the supply lever is' joggled" from petrol to paraffin, and the heat turned on, until the carburetter feels comfortably warm and the engine is running satisfactorily, when the paraffin supply is then turned fully on, and the carburetter works on paraffin.