BRITISH TRACTORS AT THE ROYAL.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Fuller Details of the New Productions. • The Triumph of the British Makers.

AT LAST I Those of us who are keen Britishers, and who happen to be interested in agrimotors will thuswise exclaim, as we realize the enormous change which has been brought about during the last few months, a change which is demonstrated perfectly and unmistakably by this year's notable Royal Show. .

The British tractor industry—we have in mind that section which is concerned with the manufacture of the lighter machine, intended for solely agricultural use—has come into its own. Seemingly swamped by a flood of American machines which, Governmentaided, swept over the land and occupied it while our engineers were concentrating all their energies and inventive skill on direct war work, it almost appeared that the trade was irrevocably lost to us.

Look around this "Victory Royal," however, and what do we find? Not only do the tractors of British make easily outnumber those of American origin, but they possess features which for practical merit are unsurpassed by anything from the other side of the "herring pond" and which, for inventive genius and sheer originality, leave America standing.

Consider the Illackstene. It is, in a way, a " hushhush " production, and we may not say so much as we should like about it. But, even confining ourselves to its engine, there is a power unit which, after the first preliminary hand turn, may be stopped and started at will for almost an indefinite time. It embodies a compressed air' starter. It is reversible, and by the simple turning of a. lever, may be started, stopped, started again in the reverse direction of rotation, stopped, and so ad infinitum.

Finally, it satisfactorily consumes paraffin from the outset, needing no preliminary doping with petrol, nor any equipment of vaporizer, water injection or • any other, what might almost be termed, artificial aids to fuel digestion. Three strong claims to originality any one of which would have sufficed to gain the title. cal2 To start this engine from cold, or, as it were, from scratch, a few turns of the starting handle serve to fill, by means of a small compressor on the front of the engine, a set of pipes. The movement of a lever, and the air thus compressed, enters the cylinder, carrying with it an injection of fuel, finely sprayed.

A movement of the control lever, and the mixture is fired, thus starting the engine. As it runs, it .continues to drive the compressor, whieh pumps air under pressure into a suitable receiver, where it is available for starting purposes at any time. The rest of this tractor is equally ingenious and full of novelty but, as we have said, we have been asked, for the present) to preserve a discreet silence. Its engine develops 30 h.p. on. the brake at 750 revs, per mm. It has two speeds, for ploughing and road work, and should be capable of cutting three average furrows in almost any • soil, and four in some.

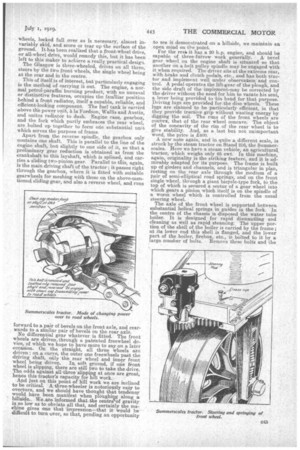

Now take the Glasgow, a product of a Scottish firm. It is remarkable rather for the bold way in which known problems have been tackled and the directness of the solutions obtained. Anyone who has watched a tractor demonstration will have observed the common fault of all rear-driven front-steered machines, when turning sharply, as at the headlands; the front wheels, locked full over as is necessary, almost invariably skid, and score or tear up the surface of the ground. It has been realized that a front-wheel drive, or all-wheel drive, would remedy this, but it has been left to this Maker to achieve a really practical design. The Glasgow is three-wheeled, drives on all three, steers by the two front'wheels, the single wheel being at the rear and in the centre.

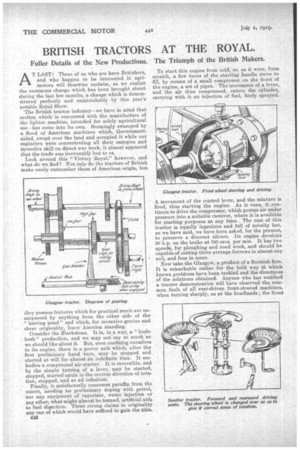

This of itself is of interest, but particularly engaging is the method of carrying it out. The engine, a norMal petrol-paraffin burning product, with no unusual or distin.otive features, occupies the famtiar position behind a front radiator, itself a capable, reliable, and efficient-looking component. The fuel tank is carried above the power unit, a in Fordson, Wallis and Austin, and unites radiator to dash. Engine case, gearbox, and the fork which partly embraces the rear wheel, are bolted up together to form one substantial unit which serves the purpose of frame.

Apart from the reverse spindle, the gearbox only contains one shaft. This is parallel to the line of the engine shaft, but slightly to one side of it, so. that a preliminary gear redaction is obtained as from the crankshaft to this layshaft, which is splined, and carries a sliding two-pinion gear. Parallel to this, again, is the main driving shaft of the tractor ; it passes right through the gearbox, where it is fitted with suitable gearwheels for meshing with those on the above-mentioned sliding gear, and also a reverse wheel, and runs

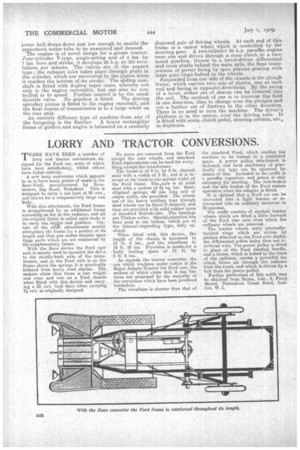

forward to a.pair of bevels on the front axle, and rearwards to a similar pair of bevels on the rear axle.

No differential gear whatever is fitted. The front wheels are driven,through a patented freewheel device, of which we hope to have more to say on a later occasion. On the straight, all three wheels are driven ; on a curve, the outer one freewheels past the driving shaft, ()illy the rear wheel and inner front wheel being driven. In. soft ground, if one front wheel is slipping, there are still two to take the drive. The odds against all-three slipping at once are great, hence this tractor's capacity for hill work. And just on this point of hill work we are inclined to be critical. A:three-wheeler is notoriously estiy to overturn, and we should have thought that tendency would have been manifest when ploughing along a hillside.. We are informed that the centrel'of gravity is so low as to obviate all that, and certainly the machine gives one that 'impression—that itwould be difficult to turn over, so that, pending an opportunity to see it demonstrated on a hillside, we maintain an open mind on the point. For the rest it has a 20 h.p. engine, and should be capable •of three-furrow work generally. A bevel gear wheel on the engine shaft is situated so that another on a belt pulley spindle may be engaged with it when required. The driver sits at the extreme rear, with brake and clutch pedals, etc., and has both tractor and implement well under observation and control. A pedal operates the lift-gear of the plough, and the side draft of theimplementanamy be corrected by the driver without the need for him to vacate his seat, a lever being provided to his hand for that purpose. Driving lugs are provided forthe disc wheels. These lugs are claimed to be particularly efficient, in that they provide tractive grip without wasting energy by digging the soil. The rims of the front wheels are convex, that of the rear Wheel concave. The object of the concavity of the rim of the rear wheel is to give stability. And, as a last but not unimportant word, the price is 2400. A new note again, and in quite a different scale, is struck by the steam tractor on Stand 216, the Summerscales. Here we have a steam vehicle, an agricultural tractor, which weighs only 65 cwt. In this machine, again, originality is the striking feature, and it is admirably adapted for its purpose. The frame is built up of girders and channels, and is triangular in plan, resting on -the rear axle through the medium of a pair of semi-elliptical road springs, and on the front single wheel, through a giant bicycle-type fork, to the top of which is secured a sector of a gear wheel into which gears a pinion which itself is on the spindle of a worm wheel which is controlled from the usual steering wheel. The axle of the front wheel is supported between substantial helical springs in guides in the fork. In the centre of the chassis is disposed the water tube boiler. It is designed for rapid dismantling and cleaning as Well as rapid steaming. The upper portion of the shell of the boiler is carried by the frame ; at its lower end this shell is flanged, and the lower part of the boiler, firebox, etc., is bolted to it by a largo number of bolts. Remove these bolts and the :tower half drops down jitst low enough to enabld the uppermost .water tube to be examined and cleaned. The engine is of novel design for a .13 team tractor. Jour-cylinder V-type, single-acting and of 4 ins. by 7 ins, bore and stroke, it develops 25 h.p. at 350 revolutions per minute. The valves are of the poppet type ; the exhaust inlet takes place through ports in the cylinder, which are uncovered by the piston when it reaches the bottom of its stroke. The sliding camshaft is fitted with duplex taper cams, whereby not only is the engine reversible, but can also be controlled as to speed. Further control is by the usual throttle valve. No gearbox is fitted. The driving sprocket pinion is fitted to the engine camshaft, and the final means of transmission is to i large wheel on the rear axle.

An entirely different type of machine from any of the foregoing is the Santler. A heavy rectangular frame of girders and angles is balanced on a centrally disposed pair of driving wheels. At each end of this frame is a castor wheel which is controlled by the steering gear. A two-cylinder 25 h.p. paraffin engine near one end drives through a cone clutch to a twospeed gearbox, thence to a bevel-driven differential and cross shafts bebind the main axle, the final transmission of power being by spur pinions gearing with large gear rings bolted to the Wheels.

Suspended from one side of the chassis is the plough frame, which carries two sets of shares, one at each end and facing in opposite4lirections. By the swing of a lever, either set of shares can be lowered into the soil. . The method of use is to traverse the field in one direction, then to change over the ploughs and cut a further set of furrows in the other direction. There is no need to turn the machine. The driver's platform is in the centre, over the driving axle. It is fitted with seats, clutch pedal, steering column, etc., in duplicate.