M ANY CONCERNS have been led by the shortage of petrol

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

during the war to experiment with suction-gas producers to replace liquid fuel for driving motor vehicles. Details of some of these have already been published, and we are now able to give particulars of another outfit which has been the subject of considerable experiment, and the main details of which have been covered by Patents Nos. 12,759 and 9,277.

The Experimental Arrangement.

The preliminary work was carried out on a Ford car, and the two photographs which we reproduce give an idea of the appearance of the outfit. It is not intended, of course, that the apparatus is to be considered as suitable for driving a car of this type. It was tried on the Ford because this was the only vehicle available at the tune, and, in addition, the experimenters were familiar with the behaviour of this car on petrol, and could, therefore, judge the comparative values of the two fuels. It must be understood that the. experimental arrangement differs as regards the layout of the plant from that recommended for permanent use on a commercial vehicle. We will, however, cluscribe briefly the outfit as made and then proceed to explain in detail the arrangement covered by the patents and shown in the diagrams which we reproduce on this page.

Referring to the apparatus as fitted to a Ford, it will be seen that the producer is mounted on the offside. It consists of the usual firebrick lining mounted in a sheet iron case. Between the sheet iron and the firebricks is a sand filling. Outside the inner sheet iron easing is another somewhat similar, the space between the two being filled with a non-conducting material.

The idea in making the casings of sheet iron is, of course, to reduce the weight of the outfit. A cast iron bottom is fitted to give strength and to form the ash pit. Fuel is fed in at the top. This is not done automatically, a supply of fuel being put in sufficient for a run of from three to four hours. The fuel feeds itself down as required, the vibration assisting this. From the producer the gas passes along a series of cooling pipes under the car. These pipes are most effective, and render unnecessary a water and coke scrubber. From the cooling pipes it passes to a sawdust scrubber which is fitted in the space designed for the petrol tank. From here the gas passes through a Mixing valve to the engine. On the near side of the car are fitted the water tank, fuel box and starting fan. The water tank is fixed at about the same level as the producer, so that it is impossible to supply water to he producer by gravity. A small pipe is therefore taken from the exhaust to the water tank, and this not only heats the water, but gives sufficient pressure to force the water over into the producer as required. In the latter is a vaporizing coil with its exit at the

boitom of thel AIr grate so that Confra, the water vapour is led to the base of the fuel zone.

Trial Run'.

Several successful runs have been made with this experimental car. The engine gives the best results after a run of about a mile, when the producer get s thor oughly hot. Plenty of power is then obtained, and a speed of 35 m.p.h. can be reached on the level with four persons in the car.

A certain number of difficulties has been...experi enced. The first was with the brickwork of the producer, which developed air leaks owing to cracks, and the vibration of the road. This was verylargely overcome by fitting spring bolts which hold the brickwork down on to its seating. The next trouble was in proportioning the correct amount of water vapour,

air and fuel, Ulti in ate", this was overcome by designing a • water carburetter which will be referred to later. The testing outfit is, or course, of a v_e r y temporary nature, but on the whole it would be fair to say that the results ob. tamed are quite as good as one would expect considering the crudenese of

the present apparatus, and the fact that it is not intended for such a light vehicle.

As Designed for a Van.

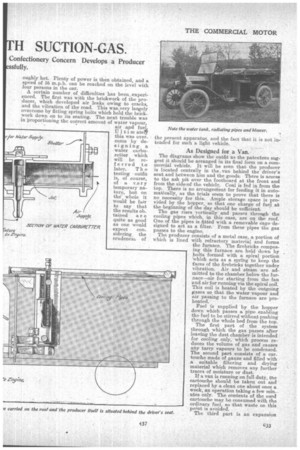

The diagrams show the outfit as the patentees suggest it should be arranged in its final form on a com mercial vehicle. It will be seen that the producer is located centrally in the_ van behind the driver's seat and between him and the goods. There is access to the ash pit over the footboard at the front and from the side of the vehicle. Coil is fed in from the top. There is no arrangement for feeding it in automatically, as the trials seem to prove that there is no necessity for this. Ample storage space is provided by the hopper, so that one charge of fuel at the beginning of the day should be sufficient. The gas rises vertically and passes through the cooling pipes which, in this case, are on the roof. One of the pipes is fitted with a removable cage designed to act as a filter. From these pipes the gas passes to the engine.

The producer consists of a metal case, a portion of which is lined with refractory material and forma the furnace. The firebricks composing this furnace are held down by bolts formed with a spiral portion 'which acts as a spring to keep the faces of the firebricks together under vibration. Air and steam are admitted to the chamber below the furnace—air for starting from the, fan and air for running via the spiral coil. This coil is heated by the outgoing gases so that the water vapour and air passing to the furnace are preheated.

Fuel is supplied by the hopper down which passes a pipe enabling the fuel to be stirred without pushing through the whole bed from the top.

The first. part of the system through which the gas passes after leaving the dust chamber is intended for cooling only, which process reduces the volume of gas and causes any tarry vapours to be condensed. The second part consists of a car-Loathe made of gauze and filled with a suitable filtering and drying material which removes any further

traces of moisture or dust. • If a van is running on full duty, the cartouche should be taken out and replaced by a, clean one about once a week, an operation taking a few minutes only. The contents of the used cartouehe may be consumed with the ordinary fuel, so that waste on this point is avoided. The third part is an expansion chamber which provides a liberal volume of gas close to the engine so that it can get its charge freely without straining the mixture or "wire drawing" it.

The mixing valve is attached to the gas pipe close to the engine ; it has been carefully proportioned and designed BO that the correct mixtures of gas and air may be obtained under road conditions with a minimum amount of air adjustment. The passages are so arranged that the air and gas are intimately mixed before entering the engine. The non-return valve works quite automatically and prevents air getting into the system at the wrong place and thereby weakening the gas, in the event of the engine stopping.

The usual type of wet scrubber has been entirely discarded, and the gas is cooled and cleaned effectively by the apparatus already described. The heat is readily abstracted from the gas by the cooling effect of the outside air acting on the large surface of the cooling pipes when the car is travelling along the road.

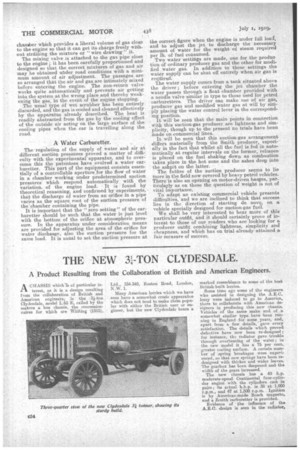

A Water Carburetter.

The regulation of the supply of water and air at different suction presSures proved a matter of difficulty with the experimental apparatus, and to over Come this the patentees have evolved a water carburetter. This part of the equipment consists essentially of a controllable aperture for the flow of water in a chamber working under predetermined suction pressures which respond automatically with the variation of the engine load. It is found by theoretical reasoning, and confirmed by experiments, that the discharge of water from an orifice in a pipe varies as the square root of the suction pressure of the chamber containing the pipe.

It is important that the "zero setting" of the carburetter should be such that the water is just level with the bottom of the orifice at atmospheric pressure. In the apparatus under consideration means are provided for adjusting the area of the orifice for water dischaaige, .also the suction pressure for the same load. It is usual to set the suction pressure at the correct figure when the engine is under fall load, and to adjust the jet -to discharge the necessary amount of water for the weight of steam required per lb. of 'fuel consumed. Two water settings are made, one for the produo tion of ordinary producer gas and the other for modified water gas. In addition to these settings the water supply can be shut off entirely when air gas is recittired. The water -supply cemes from a tank situated above the driver ; before entering the jet chamber the water passes through a float chamber provided with a needle valVe similar in type to those used for petrol carburetters. The driver can make use of air gas, producer gas arid modified water gas at will by simply placing the water control lever in the corresponding position. It will be seen that the main points in connection with this suction-gas producer are lightness and simplicity, though up to the present no trials have been made on eommercial It will be seen that this suction-gas arrangement differs materially from the Smith producer, especially in the fact that whilst all the fuel is fed in automatically at regular intervals on the former, reliance is placed on the fuel shaking down as combustion takes place in the hot zone and the ashes drop into the ashpit on the latter.

The futfire of the suction producer seems to lie more in the field now covered by heavy petrol vehicles. There is also an opening on motor-driven barges, particularly as on these the question of weight is not of

vital importance.

To adapt an existing. commercial vehicle presents diffieulties,"and we are inclined to think that success lies in the direction of starting de novo, on a vehicle specially designed for suction-gas fuel.

We shall be very interested to hear more of this particular outfit, and it should certainly prove of interest to those of our readers who are looking for a producer outfit combining lightness, simplicity and cheapness, and which has on trial already attained a fair measure of success.