Sweden Builds an Exceptional Vehicle

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

Says Laurence J. Cotton, M.I.R.T.E.

New Volvo 8-tonner Tested in Sweden Yields Economy at High Speed: Positions of Seat, Steering and Controls Make for Comfort on Long Distances

JUDGED by its build, the new Volvo 7-8-ton normal-control heaty-duty chassis well deserves the title name of Titan. It has been designed for fast long-distance haulage, as a solo machine or with trailer, and is equipped for this purpose with a 9.6-litre oil engine set to give 150 b.h.p. at 2,200 r.p.m.

Fast driving in Sweden, even on main roads, requires a sturdy chassis and extraordinary springing. The Volvo Titan is, therefore, well equipped for operation in other parts of the world, where, although the roads may be poor, the distance between main centres demands high average speed.

The Volvo 9.6-litre direct-injection engine is rather similar to contemporary British designs, except that the maximum governed speed is 2,200 r.p.m. It has unshrouded valves, with Zero-lash automatic hydraulic tappet adjusters, and wet cylinder liners. The crankcase and cylinder block are integral and a Tocco-hardened crankshaft, chromium-plated top compression rings and replaceable valve seats are used.

A direct gear drive is provided for the fuel-injection pump, which is pneumatically governed and is on the near side of the engine, as in British design. The dynamo and vacuum pump are belt-driven and 54 arranged on the opposite side of the cylinder block. Fuel passes through tandem filters attached near the fuelinjection pump and air for combustion is filtered by tandem oil-bath cleaners mounted directly on the induction manifold.

The 16-in.-diameter single-dryplate clutch and five-speed overdrivetop syncromesh gearbox are in unit assembly with the engine, having conventional mounting arrangements below crankshaft level at the front and outriggers from the • flywheel housing. These rear mountings have V-shaped ends which rest on the top flange of the chassis frame, but with rubber bobbin bushes on each side to absorb vibration and torque reaction.

Unusual details include a transmission hand brake, with the drum attached to the gearbox output shaft, a hypoid final drive, which is not normally found in a vehicle scheduled for a gross weight of about 14 tons, and alligator-pattern frame cross-members. A two-speed axle is available.

The braking system incorporates a Bendix Hydrovac booster when operated solo, but an air-pressureoperated hydraulic unit can be fitted when hauling a trailer or semitrailer having air-pressure braking equipment.

I picked out several features of the new Volvo during a one-day test, the most notable being the short time delay in the braking system and its

effectiveness. The Hydrovac unit has a 9f-in.-diameter air cylinder and 41-in. stroke.

On test, with the weight distribution as shown in the data panel, the two front and near-side rear wheels locked with a line pressure of 1,565 p.s.i. and the off-Side rear wheel began to skid at 1,460 p.s.i.

Another notable detail is the driving position. The seat is low, as in a private car, and the pedals are depressed forward and not vertically. Less effort is required in operating them, because the action is more direct. This increases comfort, especially with the steering column set at 32° to the frame.

With 11.00-20-in. tyres, a stout

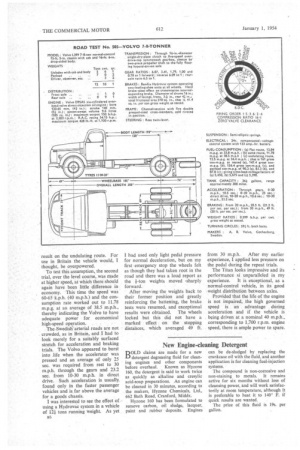

drop-sided body and the 261-gallon fuel tank filled, the Volvo weighed 5 tons 61 cwt. and with the crew and with a 7-ton load evenly distributed in the body, there was 4 tons 1 cwt. on the front axle and 8 tons 91 cwt. at the rear.

An 8-ton axle limit applies in the Gothenburg area of Sweden, and the Volvo was loaded above the regulation amount with the weights evenly distributed. In countries where the axle weight limit is higher, full advantage can be taken of the Volvo capacity for an 81-ton payload.

I drove from the works in Gothenburg to Partille for the hillclimbing tests, where the ample power available was shown by ascending the three-quarter-mile gradient of 1 in 13 average in third gear. Furthermore, stop-start tests were made in second gear on a 1-in-10 gradient and in third gear on I in 13.

Because of high labour cost, operators expect the Titan to operate the Gothenburg-Stockholm run of 320 miles in a normal working day, and my consumption test over a section of this route was made at about 40 m.p.h. The section used, from Landvetter towards Boraas, • is undulating and although most of it was covered in overdrive, there was occasion to use the direct drive for about 400 yd. on the outward run.

Dust clouds caused by oncoming lorries on a poor stretch of the road reminded me that air filtration under the bonnet must be of a high standard, and that cab dustproofing is an essential. Although, by the end of the day, the outside of the lorry was well coated with fine dust, the interior of the cab was spotless.

As the Volvo is geared for a maximum speed of about 52 m.p.h., cruising at 40 m.p.h., as it was for most part of this test, required only partthrottle and the engine was not severely taxed, its speed at this point being about 1,700 r.p.m.

Like most Continental built chassis, the Titan has a manually controlled blind in front of the radiator for rapid warming from cold, which helps to improve fuel consumption and reduce wear. A thermostat starts opening at 80° C.

(176° F.) and is fully open at 90°C. I am convinced that keeping the water temperature within this range had a material effect on the fuelconsumption return of 12.5 m.p.g. when averaging 34.4 m.p.h. for the course. On time-load-mileage, the Volvo is outstanding in performance.

The central and southern parts of Sweden are mainly level, so I made two further consumption tests over another course which is comparable with Continental manufacturers' trial grounds, being level and prac tically straight. The outward run was made at a nominal 50-55 k.p.h. (35 m.p.h.) and after the initial acceleration, the lorry was kept rolling in overdrive with light pressure on the throttle pedal.

There was little breeze to affect the result and the amount of fuel used and time taken in each direction were almost identical. This test produced a fuel return of 12.84 m.p.g. at 33.8 m.p.h. average speed, which was little different from the previous result on the undulating route. For use in Britain the vehicle would, I thought, be oyerpowered.

To test this assumption, the second trial, over the level course, was made at higher speed, at which there should again have been little difference in economy. This time the speed was 60-65 k.p.h. (40 m.p.h.) and the consumption rate worked out to 11.78 m.p.g. at an average of 38.5 m.p.h., thereby indicating the Volvo to have adequate power for economical high-speed operation.

The Swedish arterial roads are not crowded, as in Britain, and I had to look merely for a suitably surfaced stretch for acceleration and braking trials. The Volvo appeared to burst into .life when the accelerator was pressed and an average of only 25 sec. was required from rest to 30 m.p.h. through the gears and 23.2 sec. from 10-30 m.p.h. in direct drive. Such acceleration is usually. found only in the faster passenger vehicles and is far above the average for a goods chassis.

I was interested to see the effect of using a Hydrovac system in a vehicle of 12-i tons running weight. As yet I had used only light pedal pressure for normal deceleration, but on my first emergency stop the wheels felt as though they had taken root in the road and there was a loud report as the i-ton weights moved .sharply forward.

After moving the weights back to their former position and greatly reinforcing the battening, the brake tests were resumed, and exceptional results were obtained. The wheels locked but this did not have a marked effect on the stopping distances, which averaged 49 ft. from 30 m.p.h. After my earlier experience, I applied less pressure on the pedal during the repeat trials. The Titan looks impressive and its performance si unparalleled in my experience. It is exceptional, as a normal-control vehicle, in its good -weight distribution between axles.

Provided that the life of the engine is not impaired, the high governed speed is an advantage during acceleration and if the vehicle is being driven at a nominal 40 m.p.h., corresponding to 1,700 r.p.m. engine speed, there is ample power to spare.