Problems of Packing for Export

Page 96

Page 97

If you've noticed an error in this article please click here to report it so we can fix it.

A Wide Variety of Methods is Employed in Packing Commercialvehicle Chassis, etc., and some of the Difficulties to be Met in this

Connection are Here Outlined

THE packing and delivery of corn rnercial-vehicle chassis, bodies and components for export is largely in the hands of specialists in this class of work, although certain concerns, which despatch to overseas operators a large number of their products, run their own packing departments.

Among the manufacturers which carry out their own packing may be mentioned Morris Industries Exports, Ltd., Cowley, which handles the products of the Morris group of companies, Rootes, Ltd., which forms the export department of the Cornmer-Karrier group and has its packing shops at Luton, and Vauxhall Motors, Ltd., also of Luton, which, each year, ships overseas a large number of Bedford machines.

Many haulage concerns specialize in packing for delivery abroad, and one of the best-known for commercialvehicle work is LEP Transport, Ltd., which maintains a special department for dealing with private cars and goods and passenger machines at River Wharf, Chiswick, London, W.4.

The way in which a vehicle is despatched abroad varies within wide limits, and depends to a great extent upon the conditions which are prevalent at its destination, For example, chassis for Australia are generally dismantled and packed in cases, in order. to obtain the benefit of the special

duties applicable to this class of goods. Moreover, chassis for Australia and New Zealand are frequently sent without tyres as it is cheaper to pnrchase the tyres there than pay the extra duty on imported covers and tubes.

On the other hand, vehicles are often sent to other countries complete and unpacked ; buses, in particular, are a class of machine that is sent in this way. Between these two extremes, however, many methods are adopted to suit conditions in the various countries to which the vehicles are assigned.

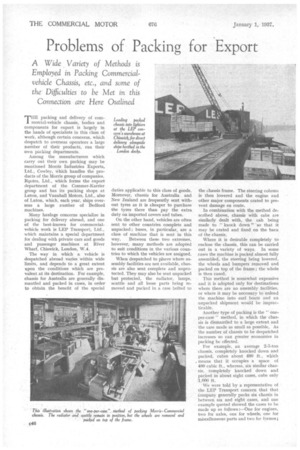

When despatched to places where assembly facilities are not available, chassis are also sent complete and unprotected. They may also be sent unpacked but protected, the radiator, lamps, scuttle and all loose parts being removed and packed in a case bolted to the chassis frame. The steering column is then lowered and the engine and other major components crated to prevent damage en route.

In combination with the method described above, chassis with cabs are similarly dealt with, the cab being made to ," knock down " -so that it may be crated and fixed on the back of the chassis.

Where it is desirable completely to enclose the chassis, this can be carried out in a variety of ways. In some cases the machine is packed almost fully assembled, the steering being lowered, the wheels and bumpers removed and packed on top of the frame; the whole is then cased.

This method is somewhat expensive and it is adopted only for destinations where there are no assembly facilities, or where it may be necessary to unload the machine into surf boats and an unpacked shipment would be impracticable.

Another type of packing is the " oneper-case" method, in which the chassis is dismantled to a large extent and the case made as small as possible. As the number of chassis to be despatched increases so can greater .economies in packing be effected.

For example, an average 2-3-ton chassis, completely knocked down and packed, cubes about 480 ft., which means that it occupies a space of 480 cubic ft., whereas, six similar chassis, completely knocked down and packed in about eight cases, cube only 1,000 ft.

We were told by a representative of the LEP Transport concern that that -company generally packs six chassis in between six and eight cases, and one

• example quoted showed the cases to be made up as follows :—One for engines, two for axles, one for wheels, one for miscellaneous parts and two for frames; the last-named are sometimes sent un

packed. At each stage of the dismantling, bolts, nuts, washers, small parts, etc., are placed in linen bags and clearly labelled, they are also re ferenced to the assembly instructions, which are enclosed, to facilitate erection on arrival.

As previously mentioned, cabs are knocked down for export, and body

work is frequently dealt with in the same way. Bodies are, therefore, shipped in convenient sections, each section being numbered or coloured to make easy the work of assembly at the end of its journey.

Haulage concerns in all parts of the country transport chassis and vehicles, either packed or unpacked, to the various docks, and LEP Transport, Ltd., is one concern which holds many contracts for handling vehicles for export. At its Chiswick premises

full facilities are available for dismantling arid packing chassis, bodies and components for export, also for reassembling vehicles that are imported into this country.

To save dock dues in the London river, loads are shipped by lighter front Chiswick to the various docks, where they moOr alongside outgoing ships. The cases are then transferred direct to the ships' holds without assistance from the dock staff. From Chiswick, LEP Transport delivers an average weight of 2,000 tons a month to ships in the London docks, and this tonnage is largely made up of commercial-vehicle chassis and components: Considerable ingenuity is necessary to reduce the dimensions of cases to the minima, and this must be done without weakening the packing case, and, in certain circumstances, without dismantling more of the vehicle than is absolutely essential. When a new type of machine is exported experiments are made to 'ensure that the smallest possible cube is obtained.

As an example of the way in which the overall dimensions are reduced, we learn that Morris Industries Exports, Ltd., when shipping a Morris-Commercial 30-cwt, chassis and cab, reduces the overall height from about 7 ft. to as low as 4 ft. 6 ins. This is done by knocking down the cab and crating it, lowering the steering and removing the scuttle, radiator, lamps, etc. The chassis is still marmenvrabIe, however, for stowage and when unloading at its destination.