MAKING BEST USE OF THE FORD.

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport which will Appeal to the Owner, Driver and Repairer.

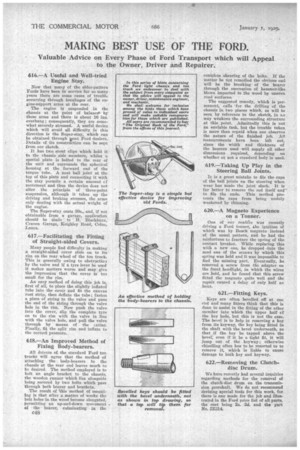

616.—A Useful and Well-tried Engine Stay.

Now that many of the older-pattern Fords have been in service for so many years there are some cases of trouble occurring through breakages of the engine-support arms at the rear.

The engine is suspended in the chassis at the point of balance* by these arms and there is about 16 ins. overhang; consequently, they are somewhat severely stressed. A useful device which will avoid all difficulty la this direction is the Super-stay, which can be obtained through West Ford dealers. Details of its construction can be sect-, from our sketch.

It has two stout dips which hold it to the chassis side members, whilst a special plate is bolted to the rear of the unit and surrounds the spherical housing at the forward end of the torque tube. A neat ball joint at the top of this plate and connecting it with the stay permits a certain amount f movement and thus the device does not alter the principle of three-point suspension, although it takes up the driving and braking stresses, the arms only dealing with the actual weight of the engine.

The Super-stay costs 30s., and, if not obtainable from a garage, application should be Made to'H. Blackburn, Craven Garage, Keighley Road, °cane, Lancs.

617.—Facilitating the Fitting of Straight-sided Covers.

Many people find difficulty in making a straight-sided cover elide on to its rim on the rear wheel of the ton truck. This is generally owing to obstractioa by the valve and if a tyre lever be used it makes matters worse and may give the impression that the cover is too small for the rim.

An easy method of doing this job is, first of all, to place the slightly inflated tube into the cover and fit the canvas rust strip, then deflate the tube ; fasten a piece of string to the valve and pass the end of the string through the valve hole in the rim. Now push the valve Into the cover, slip the complete tyre on to the rim with the valve in line with the valve hole, and pull the valve through by means of the Urine,. Finally, fit the split rim and inflate to the correct pressure.

618.—An Improved Method of Fixing Body-bearers.

All drivers of, the standard Ford ton trucks will agree that the method of attaching the body-bearers to the chassis at the rear end leaves much to be desired. The method employed is to bolt an angle bracket to the chassis, the wooden runner which lies alongside being secured by two bolts which pass through both bearer and brackets.

The result of 'this method of mounting is that after a matter of weeks the bolt holes in the wood become elongated, permitting an up-and-down movement of the bearer, culminating la the

018 complete shearing of the bolts. If the matter be not remedied the obvious end will be the breaking of the bearer through the succession of hammer-like blows imparted to the wood by uneven road surfaces.

The suggested remedy, which is permanent, calls for the drilling of the chassis in two places which, as will be seen by reference to the sketch, in no way weakens the surrounding structure at this point. Admittedly this is not an enviable task, but the trouble taken is more than repaid when one observes the nature of the finished job. All measurements have been left out, since the width and thickness .of the bearers used will supply all other dimensions required, depending on whether or not a standard body is used.

619.—Taking Up Play in the Steering Ball Joints.

It is a great mistake to file the caps of the ball joints on the steering when wear has made the joint slack. It is far better to remove the rod itself and to file the ends. This method prevents the caps from being unduly weakened by thinning.

620.—A Magneto Experience on a Tonner.

One of our readers was recently driving a Ford Nailer, the ignition of which was by Bosch magneto instead of the usual pattern, and he had the • misfortune to fracture the spring of the contact breaker. While replacing this with a new one, he dropped into the mud one of the screws by which this spring was held and it was impossible to find the missing part. Eventually, he removed a screw from the adapter on the front headlight, in which the wires are held, and he found that this screw fitted the magneto quite well and the repair caused a delay of only half an hour.

621.—Fitting Keys.

Keys are often bevelled off at one end and many fitters think that this is done to assist in the fitting of the other member into which the upper half cf the key beds, but this is not the case. The bevel is to help in removing a key from its keyway, the key being fitted in the shaft with the bevel underneath, so that if the key be tapped above the bevel, even if it be a tight fit, it will jump out of the keyway; otherwise chiselling often has to be resorted to to remove it, which is liable to cause damage to both key and keyway.

622.—Removing the Clutchdisc Drum.

We have recently had several inquiries regarding methods for the removal of the clutch-disc drum on the transmission gearshaft. We do not recommend devising special tools for this work, for there is one made for the job and illustrated in the Ford price list of all parts, the cost being 2s. 3d. and the part No. 5Z314.