• A STRIKING A.E.C. PASSENGER CHASSIS.

Page 35

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

With an Entirely New Engine and Other Major Units Embodying the • Improvements Made During Five Years, the A.E.C. Reliance Model has Been Designed to Give Fast, Safe and Silent Running.

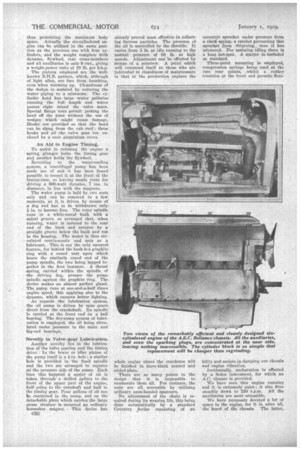

Othe new Reliance passenger AsIchassis, designed by the Associated Equipment Co., Ltd., Windmill Lane, Southall, Middlesex, whilst the major portion of the chassis is developed from existing models and embodies improvements which have been found advisable during four or five years, the engine is built on entirely new lines, practically all the older ideas having been abandoned.

Before going into details of the construction it will be of interest to say exactly what the chassis has been designed for. It is intended for high-el ass, fast passenger-carrying vehicles which shall possess the comfort and running performance of a modern private car, particular attention having been paid to the power developed, the braking, smoothness in running and silence—and these combined with long life, and general efficiency.

The capacity is for bodies to seat 30 to 35 persons. The chassis weight is 3 tons 1 cwt., of which I ton 11 cwt. is on the front axle and 1 ton 10 cwt. on that of the rear. The turning circle is GO ft. and the clearance under the rear axle 7S ins. As regards the main dimensions of the chassis, these are as follow:— Wheelbase, 16 ft.; overall length, 26 ft.; track (max.), 6 ft. I& ins. The new engine has been on test since September 29th. A large number of the chassis is in course of manufacture, and there are five vehicles actually in service. An unusual feature of endurance has been performed by the

engine, which ran. a• 100-hours fullpower non-stop test, during which time it made 9,500,000 revolutions. The average consumption was .57 pt. per b.h.pehour—an excellent figure: the curve showing horse-power gave a straight line up to 2,000 nests, and the maximum of 102 b.le.p. at 2,500 r.p.m.

.The bore and stroke of the six cylinders are 100 mm. and 130 rum. respectively. La the interests of general efficiency and accessibility for valve adjustment an overhead camshaft and overhead valves are employed. This camshaft is driven by a Duplex roller chain followed by a pair of helicalspurgears, the first pinion of which is split, the halves being separated • by two light compression springs, thus taking up any backlash and giving silent sunning.

small friction clutcle is provided in the fait centre and the drive is by enclosed chain. Only the one chain is employed in the timing, as the helicalspur pinion for the camshaft drive is

mounted on the fan spindle, which is carried on ball bearings. The camshaft is carried in an oil trough and the valves are operated through the medium of rocker arms with adjustable pins bearing on the valve stems. These stems have double coil springs.

One of the aims in the design has been to provide such a simple block of cylinders that it would be less expensive to replace the whole block than to regrind them and Kt new pistons.

A most successful effort has also been made to clean up the whole design and to keep the off side clear of any auxiliaries; even the sparking plugs are at the near side, and, considered as a whole, the unit is one of the nicest pieces of engineering rwe have seen for a long time.

Seven bearings are provided' for the 2S-iii. diameter crankshaft, the pins of which are bored out eccentrically to reduce the rotating mass, the ends of the bored holes being closed by pressed-steel cups retained by a bolt. The bearing for taking the thrust on the crankshaft is at the front end for an important reason. With a bearing situated at the rear of the crankshaft the differenee in expansion between the crankshaft and the aluminium crankcase is apt to make the timing chain run askew. This is a point which is not often appreciated.

The connecting rods are of highquality steel with the small ends clamped on to the hollow gudgeon pins. To give great strength the crankcase is heavily webbed and the cylinder-holding-down bolts pass right through to carry the main-bearing caps. These

constructional featares and the monobloc cylinder casting, combined with perfect balancing of the various parts, make the engine entirely free from periods and vibrations'. The unit is extremely compact, the overall length from the front of the fan to the back of the cylinders being only 3 ft. 9 ins„ thus permitting the maximum body space. Actually the six-cylindered engine can he utilized in the same position as the previous one with four cylinders, and the weight complete with dynamo, flywheel, rear cross-members and all auxiliaries is only 9 cwt., giving a weight-power ratio of 10 lb. per b.h.p.

The pistons employed are the wellknown B.H.E. pattern, which, although of light alloy, are free from knocking, even when warming up. Cleanliness of the design is • assisted by reducing the water piping to a minimum; The cylinder head has large -.water galleries running -the full length and water passes right round the valve seats. Special flange nuts permit jacking the head off the joint without the use of wedges Which might cause damage. Hunks" are provided so that the head can be slung from the cab roof ; these hooks and all the. valve gear ore enclosed by a neat aluminium cover.

An Aid to Engine Timing.

To assist in retiming the engine a spring; plunger locks the timing gear and another holds the flywheel. .

Reverting to the water-cooling system, a centrifugal pump has been made 118C of and it has been found possible to mount it at the front of the timing-case, so leaving ample room for driving a 600-watt dynamo, 7 ins. in diameter, in line with the ina,gneto.

The water pump is held by two nuts only and mot be removed in a few moments, as it is driven by. means of a dog and /IRS to be withdrawn only

in. to become free. The rotor spindle runs in a white-metal hush with a spiral groove. so arranged, that, when running, water is induced to the rear end of the hnsh and retail-us by a straight groove below the bush and cut in the housing. The water is thus circulated continuously and acts as a lubricant.. This is not the only unusual feature, for behind the bush is a graphite ring with a .coned seat upon which bears the similarly coned end of the pump spindle, the two being lapped together in the first instance. A thrust .spring, carried within the spindle of the driving dog, presses the pump spindle, against, the graphite ring. The device makes an almost perfect gland. The .pump runs at one-and-a-half times engine speed, this applying also to the dynamo, which ensures better, lighting.

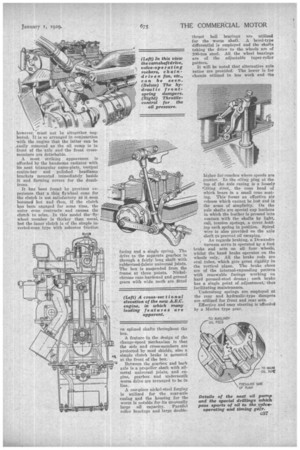

As regards the lubrication system, the oil pump is driven by spur gears direct from the crankshaft. Its spindle is carried at the front end on a ball bearing. The dry-sumpsystem of lubrication is employed, the oil being circulated under pressure to the main and big-end bearings.

Novelty in Valve-gear Lubrication.

Another novelty hies' in the lubrication of the valve gearing and the timing drive. In the lower or idler pinion of the pump itself is a Fin. hole ; a similar hole is 'provided in the fixed spindle and the two are arranged to register On the pressure side of the pump. Each time this happens a squirt of oil is taken through a drilled gallery to the front of the upper part of the engine, half going to the camshaft and half to the timing gear. Four gallons of oil Can be cantained in the sump, and on the detachable plate which carries the large gauze strainer is mounted an ordinary horseshoe magnet. . This device has

already proved most effective in collecting ferrous particles. The pressure of the oil is controlled by the throttle. It varies from 5 lb. at idle running to the normal pressure of 60 lb. at high speeds. Adjustment can'be effected by means of a setscrew. A point which will commend itself to those who are interested in cleanliness of maintenance is that in the production engines the whole engine above the crankcase will he finished in stove-black enamel and nickel-plate.

There are so many points in the design that it is impossible to enumerate them all. For instance, the nuts are all accessible by utilizing ordinary open-handed spanners.

No adjustment of the chain is required during its wearing life, this being done automatically by a standard Coventry .device consisting of an

eccentric sprocket under .pressure from a clock spring, a ratchet preventing this sprocket from retnrning„ once it has advanced. For assisting idling there is a long.hot-spot. A starter is-included as standard.

Three-point mounting is employed, compression springs being used at the

two rear points, a rubber trunnion at the front end permits flexi

bitity and assists in damping out chassis and engine vibration.

Incidentally, carburation is effected by a Solex instrument, for which an A.C. cleaner is provided.

We have seen this engine running and it is extremely quiet; it also fires steadily down to 150 r.p.m. All the auxiliaries are most accessible.

We have purposely deviated a lot of space to the engine, for it is, after all, the heart of the' chassis. The latter, however, must not be altogether neglected. It is so arranged in conjunction with the engine that the latter can be _easily removed as the oil sump is in front of the axle and the front crossmembers are detachable.

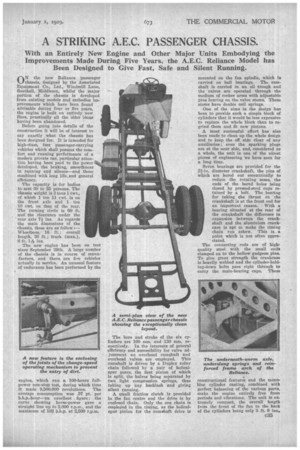

A most striking appearance is afforded by the handsome radiator -with its neat triangular name-plate, vertical centre-bar and polished headlamp brackets mounted immediately beside it and forming covers for the dumbirons.

It has been found by previous experience that a thin flywheel cone for the clutch is not satisfactory as it soon becomes hot and thou, if the clutch has been engaged for some time, the outer cone contracts and causes the clutch to seize. In this model the flywheel member is thicker than usual, hat the inner clutch is of the simple inverted-cone type with asbestos friction facing and a single spring. The drive to the separate gearbox is through a fairly long shaft with rubberized-fabric universal joints. The box is suspended from the frame, at three points. Nickelchrome case-hardened and ground gears with wide teeth are fitted

on splined shafts throughout the box.

A feature in the design of the chauge-speed mechanism is that the side and cross-members are protected by mud shields, also a simple clutch brake is mounted at the front of the box.

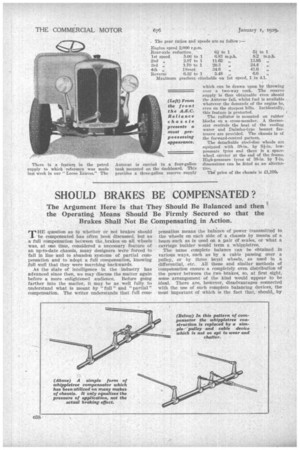

Between the gearbox and back axle is a propeller shaft with allmetal universal joints, and engine, gearbox and Underneath worm drive are arranged to be in line.

A one-piece nickel-steel forging is utilized for the rear-axle casing and the housing for the worm is notable for its unusually large oil capacity. Parallel roller bearings and large double thrust ball bearings are utilized for the worm shaft. A bevel-type differential is employed and the shafts taking the drive to the wheels are of 100-ton steel. All the wheel bearings are of the adjustable taper-roller pattern.

It will be noted that alternative axle ratios are provided. The lower is for chassis utilized in bus work and the higher for coaches where speeds are greater. In the oiling plug at the top of the axle casing is a loosely *fitting rivet, the cone head of which bears in a small cone seating. This forms an effective air release which cannot be lost and i$ the acme of simplicity: On the axle shafts are special cup leathers in which the leather is pressed into contact with the shafts by light, coil, tension springs, a covet holding each spring in position. Spiral wire is also provided on the axle shaft to prevent oil escaping.'

; As regards braking, a Dewandre vacuum servo is operated by a foot brake and acts on all four wheels, whilst the band brake operates on the wheels only. All the brake rods are oval tubes, which give great rigidity in the vertical plane. The brake shoes are of the internal-expanding pattern with renewable facings working on hard pressed-steel drums ; each brake has a single point of adjustment, thus facilitating maintenance.

Underslung springs are employed at the rear and hydraulic-type dampers are utilized for front and rear sets.

Effective and easy steering is afforded by a Marks type gear. There is a feature in the petrol supply to which reference was made last week in our "Loose Leaves." The Autovac is carried in a four-gallon tank mounted on the dashboard. This provides a three-gallon reserve supply which can be drawn upon by throwing over a two-way cock. The reserve supply is thus obtainable even should the Antovac fail, whilst fuel is available whatever the demands of the engine he, even on the steepest hills. Incidentally, this feature is protected.

The radiator is mounted on rubber blocks on a cross-member. A thermostat controls the beat of the cooling water and Daimler-type bonnet fasteners are provided. The chassis is of the forward-control pattern.

The detachable steel-disc wheels are equipped with 38-in. by 8i-in. lowpressure tyres and there is a sparewheel carrier at the end of the frame. High-pressure tyres of 38-in. by 7-in. dimensions can be fitted as an alternative.

Theprice of the chassis is 11,100.