THE COLLECTORS

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

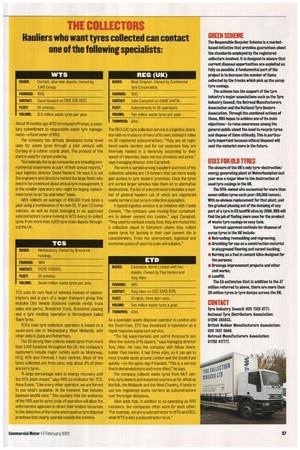

Hauliers who want tyres collected can contact one of the following specialists:

About 18 months ago WTS introduced vPrompt, a voluntary commitment to responsible waste tyre management—a forerunner of RRS.

The company has already developed some novel uses for waste tyres through a joint venture with Duralay in a rubber crumb plant. The product of this plant is used for carpet underlay.

"Increasingly the large companies are including environmental statements as part of their annual reports," says logistics director David Bavaird. He says it is not the engineers and directors behind the large fleets who need to be convinced about ethical tyre management, it is the smaller operators who might be buying replacement tyres on an "as-and-when" basis.

AWS collects an average of 400,000 truck tyres a year using a combination of its own 32,17 and 7.5-tonne vehicles, as well as those belonging to six approved subcontractors (some running in WTS livery) to collect tyres from more than 5,000 tyre chain depots throughout the UK.

TCS uses its own fleet of vehicles instead of subcontractors and is part of a larger transport group that includes Otis Vehicle Solutions (vehicle rental, truck sales and parts), Brandrick Truck, Brandrick Leasing and a tyre retailing operation in Birmingham called Team Tyres.

ICS's main tyre collection operation is based on a seven-acre site in Vi/ednesbury, West Midlands, with other sites in Zeais and Rotherham.

The 20-strong fleet collects waste tyres from more than 1,000 locations throughout the UK; the company's customers include major outlets such as Motorway, Hi-Q, NTA and Formula 1 Auto centres. Most of the tyres collected are from cars; only about 8% of them are lorry tyres.

''A large percentage went to energy recovery until the SITA plant closed,' says RRS co-ordinator for TCS, Anne Evans. "Like every other operator, we are forced to use what's available. At the moment, that includes licensed landfill sites." She explains that the existence of the RRS and its strict code of operation will allow the enforcement agencies to direct their limited resources to the detection of the more unscrupulous tyre disposal practices that clearly operate outside the scheme. The REG (UK) tyre collection service is a logistics operation with no trucks or drivers of its own; instead it relies on 26 registered subcontractors. "They are all registered waste carriers and for our purposes they are internally ranked in a hierarchy according to their speed of response, basic service provision and price," says managing director John Campbell.

The work is spread among suppliers and most of the collection vehicles are 7.5-tonners that can more easily gain access to tyre dealers' premises. Once the tyres are sorted larger vehicles take them on to alternative destinations. The fist of subcontractors includes a number of general hauliers (all of which are registered waste carriers) but no tyre collection specialists.

A typical logistics solution is an initiative with Castle Cement. "The company uses moving-Floor curtainsiders to deliver cement into London," says Campbell. "They used to run back empty Now, they are routed into a collection depot in Edmonton where they collect waste tyres for burning in their own cement kiln in Leicestershire. From the environment, logistical and economic points of view it is a win-win solution."

As a specialist waste disposal operator in London and the South-East, ETD has developed a reputation as a rapid-response waste tyre service.

The big supermarkets and petrol forecourts are often the victims of fly tippers," says managing director Tony Allen. He runs the company with fellow shareholder Paul Hanlon. It has three sites, so it can get to most trouble spots around London and the South-East quickly—on the same day if needed. "This is a service that is demanded more and more often," he says.

The company collects waste tyres from MoT centres, tyre dealers and industrial sources as far afield as Norfolk, the Midlands and the West Country. It tends to use two registered waste carriers as subcontractors over the longer distances.

Allen adds that, in addition to co-operating as RRS members, the companies often work for each other: "For example, we are a subcontractor to WTS and REG, while WTS is also a subcontractor to us."