Tread ightl

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Since John Boyd Dunlop invented the pneumatic lyre in 1888 the manufacturers have been trying to sell those black round things by saying theirs last longer or give better grip. Now they have, almost in unison it appears, taken a new tack...

"ours uses less fuel".

Continental started the trend for fuelfriendly tyres in a small way with its EOT trailer tyres, but Michelin is now starting production of its Energy tyre, Pirelli, Avon and Dunlop have products under development. Although Continental has EcoPlus, a range of low rolling resistance truck and trailer tyres on sale on the Continent they won't be available in the UK until later this year. Bridgestone has a product in the US but does not think it is as applicable to the European market. Goodyear has just launched its G465 which has elements in its design to reduce rolling resistance.

So how do tyres save fuel? By lowering the rolling resistance, chorus the tyre companies. Given that tyre companies use super computers to design the tread pattern how can they suddenly say that they have cut rolling resistance, and what effect will it have anyway?

Quite considerable, is the answer from Michelin. It reckons that a 20% reduction in tyre rolling resistance equates to an (initial) 6% saving in fuel. It says operators often don't notice savings below 5%. With fuel accounting for about 66% of the running costs of an artic, such economies can amount to many thousands of pounds every year.

However, such savings are not for everyone, insists Michelin, you need to be on long-distance work This is because the technology employed means the tyre is not as good at resisting the repeated stop/start motoring with tight cornering endured in multi-drop operations. Basically if you are wearing out A-type tyres (XZA and so on) in under 130,000km (80,000 miles) your operation is too arduous to get a benefit out of low rolling resistance tyres, says Michelin. 'A' Replacement

wear Its fuel economy calculations are based on a diesel

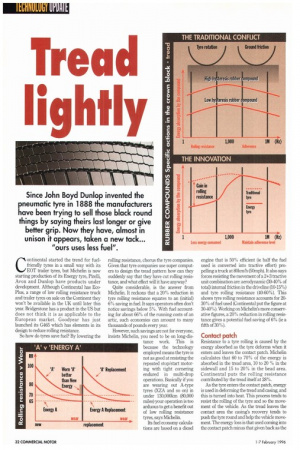

engine that is 50% efficient (ie half the fuel used is converted into tractive effort) propelling a truck at 80km/h (50mph). It also says forces resisting the movement of a 2+3 tractive unit combination are: aerodynamic (30-40% of total) internal friction in the driveline (10-15%) and tyre rolling resistance (40-60%). This shows tyre rolling resistance accounts for 2030% of fuel used (Continental put the figure at 30-40%). Working on Michelin's more conservative figures, a 20% reduction in rolling resistance gives a potential fuel saving of 6% (ie a fifth of 30%).

Contact patch

Resistance to a tyre rolling is caused by the energy absorbed as the tyre deforms when it enters and leaves the contact patch. Michelin calculates that 60 to 70% of the energy is absorbed in the tread area, 10 to 20 % in the sidewall and 15 to 20% in the bead area. Continental puts the rolling resistance contributed by the tread itself at 28%.

As the tyre enters the contact patch, energy is used in deforming the tread and casing, and this is turned into heat. This process tends to resist the rolling of the tyre and so the movement of the vehicle. As the tread leaves the contact area the casing's recovery tends to push the tyre round and help the vehicle movement. The energy loss is that used coming into the contact patch minus that given back as the

tyre leaves the road (called hysteresis). Lowhysteresis rubber, redesigned casings and new tread patterns are keys to reduce rolling resistance. All the manufacturers are now coming up with low hysteresis rubber, not for the tread (as wear and grip dictate the compound), but for the under tread area.

Although this low hysteresis concept has been around for some time, the problem has been that it did not allow the tread to grip well enough at high frequencies—where it is needed for adhesion to the road surface.

Basically, the harder rubber wouldn't deform quickly enough to allow adequate contact with the road. The manufacturers seem to have cracked this problem by producing a rubber that changes properties depending of the frequency

Rolling resistance

Reducing the zig-zag tread pattern to a predominantly radial gioove is an industrywide move as this not only reduces the rolling resistance, but also the noise. While these give excellent steering, work had to be done on adhesion under braking—traditionally supplied by the lateral part of the grooves. Michelin has replaced these with small cuts (sip es) across the tread, to the full depth of the tread, and with cuts down the side of the main tread grooves. It says these provide adhesion for braking effort while reducing "tread shuffle" and thereby rolling resistance.

On the drive axle the need to transmit the tractive effort dictates a tread pattern with lots of lateral grooves. Michelin has opted for a tread pattern with "self supporting" blocks which are inclined forward by 12. As the tread flexes when it comes into the contact patch, the blocks stand upright and lock against each other. However, this means the tyre can only be fitted one way round. Michelin says that lowering the "tread shuffle" reduces wear and allows shallower tread depth without loss of tyre life. This not only further reduces rolling resistance but also noise.

Continental has concentrated its efforts primarily in the casing area, arguing that changing the tread pattern to lower rolling resistance could compromise the grip and tyre life. While its treads have been redesigned these are in the light of operational considerations and not to reduce rolling resistance. To lower this Conti has made the belt wider to stabilise the tread, and used low hysteresis rubber in the casing.

Michelin has reprofiled the crown of the casing to make the tyre sit flatter on the road thereby equalising the pressure on the ground. This reduces thread "shuffle" and so reduces the energy absorbed.

Also Mercedes has reduced the angle of inclination of the wires in the first working ply from 26 to 18° to increase the rigidity of the tread band, reducing deformation and hence energy consumption.

Before everyone gets carried away and rushes out to buy a set for comparison to the rest of the fleet, Michelin points out some difficulties As tyres wear their rolling resistance decreases. So while Energy tyres, new for new, have a rolling resistance 20% lower than existing tyres, a new Energy tyre still has a higher rolling resistance than a well worn ordinary tyre!

Net result

As Energy tyres wear, their advantage in lower rolling resistance falls from 20% (on a new-for-new comparison) to around 5% (when comparing worn-for-worn). Therefore the potential fuel savings decrease from an initial 6% to give an overall net result of 4%, says Michelin. This figure includes regrooving and removing tyres before they are fully worn down to be sent for retreading.

All the manufacturers say that a great deal of the advantages of their low rolling resistance tyres can be lost in retreading. Pirelli puts the figure at 65%, Michelin won't be drawn. Within a year or so it will be possible to have Energy tyres retreaded with new rubber to the original compound. The others will all inevitably follow suit after their products are launched.

On the cost front, Michelin says its Energy tyres carry a 7% premium over their A-type counterparts. On list price that equates to around £30 or about £360 fora 2+3 com bination. If Michelin's figures are correct that sum would be easily recovered over 130,000km of the tyres life—and then there is the retread.

For those on long-distance haulage where low rolling resistance tyres come into their own a 4% fuel saving must be worth a try. U by Colin Sowman

Reducing the zigzag tread pattern to a predominantly radial groves is an industry-wide move as this not only reduces the rolling resistance, but also the noise.