R enauit Truck Industries (RTI) in the UK, has recently replaced

Page 109

Page 110

Page 111

Page 112

If you've noticed an error in this article please click here to report it so we can fix it.

virtually all of its range. The latest models to be introduced are the new Midliner range, which covers the 8.5 to 13 tonne gross weight sector.

Higher power is a feature of the new Midliners all of which, apart from the Perkins-powered S120 variant, have Renault engines.

The model featured here, the 103 kW (138hp) SI40 is effectively Renault's lowest powered mainstream 7.5-tonner. This situation arises as the 89.5 kW (121hp) output S120 is primarily offered for municipal/public utility applications.

These new models, although externally similar to their predecssors, have been considerably redesigned paying particular attention to making major time savings in the routine servicing schedules.

Renault dealer Rawson's service director Don Parkes explained that standard Midliner services are required at 15,000km intervals. These can be extended to 30,000km frequency if the truck uses long life MV8, MV3 or MV4 engine oil and is mainly operated on long-distance road haulage.

Midliners' have three levels of routine servicing. The service cycle is A, B, A, C. Recommended time, according to Midliner model, for the A service is only 0,3 hour, the intermediate B service, 3.4 hours and the major C service 5.4 hours.

To see how these service time reductions have been achieved Workshop watched Rawson's hard worked Midliner S140 demonstrator through its service.

As the Midliner is only newly available, senior technician David Acott, 24 years with Rawsons, undertook to outline the key elements from all three routine Midliner services.

by Phil Reed The engine oil has to be drained and the oil filter changed at every service. Special attention also has to be paid to draining the engine's oil cooler element at the same time as changing the oil and filter. Acott has a spanner on the oil cooler element drain plug to show its position. His left hand is on the coolant water filter/treatment element, which is also grouped in this service area. This needs changing every two years. Like the oil filter, this is a spin on canister. The water filter/treatment housing self-seals when the canister is removed removing the need to drain or bleed the coolant system after changing the element.

1

2 Midliners at 7.5 tonnes have

drum brakes. The condition of the linings can be easily check ed through inspection windows in the brake back plates. The brakes are self adjusting on both axles. Parabolic springs are fitted to the Midliner 7.5tonners front axle. Acott indicates the jacking points that should be used if an operator is lifting a wheel. The jack should not be positioned on the vehicle's springs. Acott also points out that care should be taken when using a large trolley jack to lift the front end of the Midliner. The jack's lifting cradle must be positioned so that it applies pressure only to the beam axle — and not the anti-roll bar.

3 With one exception all the 15

grease points on this particular Midliner can be reached from under the vehicle. Most are very easy to see and attend to with the grease gun. RTI stress that the propellor shaft grease nipples, often overlooked, should receive regular attention. Acott also indicates here the clutch release bearing greasing point as being another frequently missed item by operators carrying out their own servicing. The only grease point requiring attention above ground is on the brake-lever bell crank. This is positioned at the forward end of the chassis and can be reached when the cab is tilted.

Acott believes in paying proper attention to the areas of lubrication which do not have grease points. The Renault service sheet lists a number of these items, including lubricating cab door hinges, window winders, locks and the like. Over the years Acott has devised his own comprehensive list of items needing regular lubrication. These points he automatically covers with every vehicle service. Acott's study of the new Midliner marks the cab tilt mechanism, accelerator cable, gear linkage extension tube (pictured) and under-cab-floor gearlever mechanism as being worthy of regular lubrication.

One of the maintenance reducing features of the new Midliner is the self-adjusting clutch. This is a hydraulically actuated, single-plate unit using asbestos-free linings. It thus requires little other than routine attention at services. Hydraulic fluid level has to be checked and the slave cylinder unit inspected. Acott is seen here checking the protective cover around the slave cylinder to ensure the unit's seal is not leaking. This clutch checking procedure should be carried out every service. Both rear axle and gearbox oil level/fill plugs are magnetic and easy to get at. Acott points out that when these items are checked to the plug should be left out for a few minutes after topping up. Gear oil is fairly thick and at the completion of the filling/topping up operation it takes time for the excess oil to drain away through the leveUfill hole. It is advisable to let the level settle and the excess oil drain away — as too much oil in the axle or gearbox can cause excess internal pressure and hence blow oil seals. Midliner gearbox and axle oil should be drained and changed every Cservice.

7 Another item requiring atten

tion at the C-service is the brake load-sensing valve. If this requires attention Renault distributors have special equipment to check and reset this item. This measures input and output pressures on the brake's air system, and is quickly fitted. While in this area an experienced look at the main spring assembly of the load sensor indicated to Acott that some judicious pruning was required. A rapid application of a hacksaw removed the excess metal from the short section of the load sensing mechanism which was protruding below the level of the lowest point of the rear axle. Headlamp beam adjustment and front indicator/headlight bulb replacement can be carried out without using any tools. Access to the back of each headlight is made through individual hinged panels each side of the grille. The front indicator lamp assemblies are carried in this panel. Headlight beam adjustment can also be carried out, without any further disassembly, at this stage. To change the headlight bulb the light unit has to be detached from three clips which allows it to be lifted forward to obtain access to the bulb. At both the B and Cservice, Renault recommends that the engine breather is cleaned. This is mounted on the engine rocker cover and easy to get at. Care should be taken not to tear the gasket (nearest the camera) between the breather assembly and the rocker cover. Once the breather is removed from the engine's rocker cover casting it can be disassembled for cleaning on the bench. No gasket is fitted between the breather's vent tube and the main breather casting. Silicon sealer should be used to make this joint before re-assembly.

10 Valve tappet clearances

should be checked on the C-service. First, isolate the battery by using the switch as the electrical connections for the preheater solenoid, mounted on the top of the rocker cover, has to be disconnected. The rocker cover is retained by domed nuts. These have rubber 0-ring seals which should be replaced on assembly. Acott also stresses that the rocker cover should be removed very carefully to prevent its gasket, which loops over two cylinder-head studs, from tearing. Acott points out that for adjustment purposes number 1 cylinder is the rearmost one, not the front one as with most other engines.

11 The MIDS.060212 engine

has four cold-start heater plugs mounted in the inlet air cross-over. Renault recommend that these plugs are changed every C-service. These plugs are easy to check for operation as they are wired so that if one unit falls, none will work. Thus to check the operation of the heater plugs at A or B-services requires only that the cold start is actuated. If all the plugs are working the heating effect can be felt on the outside of the cross-over. If no heat can be felt then at least one of the plugs has failed. In normal service, however, Acott's believes that these heating plugs are reliable.

12 The power-steering fluid

level should be routinely checked — a dipstick is provided for this operation. At the C-service the gauze filter unit, which is in the power-steering reservoir filler neck, should be renewed. Acott also believes that it is essential to check that the main pipes to and from the reservoir are secure and not chafing. The pipework of the new Midliner, be it for brakes or power steering, is well grouped and bracketed. Provided these brackets and the associated clips and fixings are properly maintained, pipe chafing should be eliminated.

13 The service schedule calls

for the exhaust brake op eration to be checked at regular intervals. Acott also believes in cleaning the cab-floor around the actuator button to prevent any chance of the actuator being jammed. Acott is seen here actuating the button by hand to see whether the external mechanism of the butterfly exhaust brake is working. A second person is needed to check that the shut-off lever on the fuel pump is working at the same time the brake actuator is pressed. A guillotine-type exhaust brake is also used on the Midliner.

14 Renault advises that the

Midliner's spin-on fuel fil ter element is changed at every service. The Midliner fuel system is designed so that it is easy to bleed after the filter is changed. Loosen off the bolt on top of the filter housing and prime the filter using the hand pump on top of the fuel injection pump, shown here. When bled the bleed screw can then be tightened and the injectors bled through. Acott points out that the injector pipes are very thoroughly clamped and carefully routed. Where there is a possibility that chafing can take place, plastic sleeves have been fitted over the injector feed pipes.

15 Renault has a special tool

available to measure fan belt tension. However, an experienced fitter can measure the correct tension by feel. In the case of the 5140 Midliner the belt should have no more than about 6mrri of play in either direction on the longest unsupported part of the belt length. This length of belt can be easily reached just below and in front of the alternator. If the belt needs adjusting the single screw adjuster on the alternator mounting (shown) is provided for tensioning. At the same time as the belts are checked for tension, they should also be visually inspected for cracking on the inner faces.

16 The Midliner's dry element

air filter should be inspect ed every service. It is posi tioned rearwards of the offside front wing. Blow out the filter with an airline and check the outer rubber seating ring to ensure that it is clean and intact. The seal on the rear face of the dry filter element must also be checked for damage. While the filter element is out, the inside of the casing should be thoroughly wiped clean and the same time the gauze in the intake cowl should be cleared of leaves or other debris. If the filter clog indicator shows too high a degree of restriction, the dry element must he replaced.

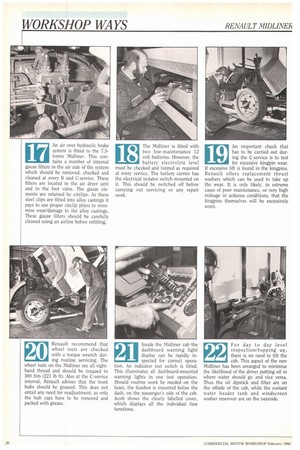

17 An air over hydraulic brake

system is fitted to the 7.5 tonne Midliner. This con thins a number of internal gauze filters in the air side of the system which should be removed, checked and cleaned at every B and C-service. These filters are located in the air dryer unit and in the foot valve. The gauze elements are retained by circlips. As these steel clips are fitted into alloy castings it pays to use proper circlip pliers to minimise wear/damage to the alloy castings. These gauze filters should be carefully cleaned using an airline before refitting.

18 The Midliner is fitted with two low-maintenance 12

volt batteries. However, the battery electrolyte level must be checked and topped as required at every service. The battery carrier has the electrical isolator switch mounted on it. This should be switched off before carrying out servicing or any repair work.

19 An important check that has to be carried out dur

ing the C-service is to test for excessive kingpin wear. If excessive lift is found in the kingpins. Renault offers replacement thrust washers which can be used to take up the wear. It is only likely, in extreme cases of poor maintenance, or very high mileage in arduous conditions, that the kingpins themselves will be excessively worn.

20 Renault recommend that wheel nuts are checked

with a torque wrench dur ing routine servicing. The wheel nuts on the Midliner are all righthand thread and should be torqued to 300 Nm (221 lb ft). Also at the C-service interval, Renault advises that the front hubs should be greased. This does not entail any need for readjustment, as only the hub caps have to be removed and packed with grease.

Inside the Midliner cab the 21 dashboard warning light

display can be rapidly in spected for correct operation. An indicator test switch is fitted. This illuminates all dashboard-mounted warning lights in one test operation. Should routine work be needed on the fuses, the fusebox is mounted below the dash, on the passenger's side of the cab. Acott shows the clearly labelled cover, which displays all the individual fuse functions.

22 For day to day level

inspection/topping up, there is no need to tilt the cab. This aspect of the new Midliner has been arranged to minimise the likelihood of the driver putting oil in where water should go and vice versa. Thus the oil dipstick and filter are on the offside of the cab, while the coolant water header tank and windscreen washer reservoir are on the nearside.