Special shell pipe lifter

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

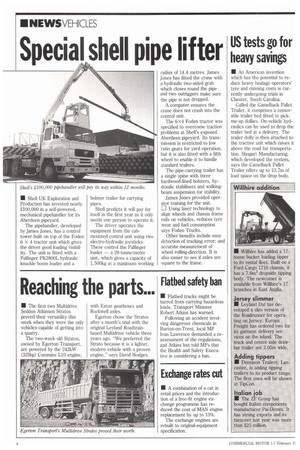

• Shell UK Exploration and Production has invested nearly £100,000 in a self-powered, mechanical pipehandler for its Aberdeen pipeyard.

The pipehandler, developed by James Jones, has a control tower built on top of the Foden 6 x 4 tractor unit which gives the driver good loading visibility. The unit is fitted with a Palfinger PK2800L hydraulic knuckle boom loader and a bolster trailer for carrying pipes.

Shell predicts it will pay for itself in the first year as it only needs one person to operate it.

The driver operates the equipment from the cabmounted control unit using two electro-hydraulic joysticks. These control the PaWinger loader — a 28-tonne/metre unit, which gives a capacity of 1,500kg at a maximum working

radius of 14.4 metres. James Jones has fitted the crane with a hydraulic two-sided grab which closes round the pipe and two outriggers make sure the pipe is not dropped.

A computer ensures the crane does not crash into the control unit.

The 6x4 Foden tractor was specified to overcome traction problems at Shell's exposed Aberdeen pipeyard. Its transmission is restricted to low ratio gears for yard operation, but it is also fitted with a fifth wheel to enable it to handle standard trailers.

The pipe-carrying trailer has a single spine with three hardwood-lined bolsters, hydraulic stabilisers and walkingbeam suspension for stability.

James Jones provided operator training for the unit.

Using laser technology to align wheels and chassis frame rails on vehides, reduces tyre wear and fuel consumption says Foden Trucks.

Other benefits include easy detection of tracking error; and accurate measurement of wheel roiling-direction. It is also easier to see if axles are square to the frame.