A RIGID SIX-WHEELER FOR 10-TON LOADS.

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

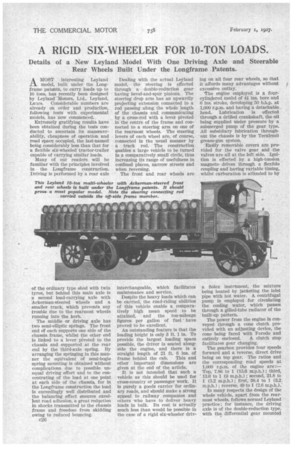

Details of a New Leyland Model With One Driving Axle and Steerable Rear Wheels Built Under the Longframe Patents.

AMOST interesting Leyland model, built under the Longframe patents, to carry loads up to 10 tons, has recently been designed by Leyland -Motors, Ltd., Leyland,

a on numbers are

cs. Considerable nd

already on order a production, following tests with experimental models, has now commenced. Extremely gratifying results have been obtained during the tests conducted to ascertain its manceuvrability, cheapness of operation and

road space occupied, the last-named that being considerably less than at for a flexible six-wheeled tractor-trailer capable of carrying similar loads.

Many of our readers will be familiar with the principles involved in the Longframe construction. Driving is performed by a rear axle

of the ordinary type shod with twin tyres, but behind this main axle is a second load-carrying axle with Ackerman-steered wheels and a smaller track, which prevents any trouble due to the rearmost wheels running into the kerb. The middle or driving axle has two semi-elliptic springs. The front end Of each supports one side of the chassisframe, whilst the other end Is linked to a lever pivoted to the chassis and supported at the rear end by the third-axle spring. By arranging the springing in this manner the equivalent of semi-bogie spring mounting is obtained without complications due to possible unequal driving effort and to the concentrating of the load at one point at each side of the chassis, for in the Longframe construction the load Is exceedingly well distributed and the balancing effect ensures excellent road adhesion, a great reduction In shocks transmitted to the chassis frame and freedom from skidding owing to reduced bouncing.

c26

Dealing with the actual Leyland model, the steering is effected through a double-reduction gear having bevel-and-spur pinions. The steering drop arm has an upwardly projecting extension connected to a rod passing along the whole length of the chassis and communicating by a cross-rod with a lever pivoted in the centre of the frame and connected to a steering arm on one of the rearmost wheels. The steering levers of each wheel are, of course, connected in the usual manner by a track rod. The construction enables a large vehicle to be turned in a comparatively small circle, thus increasing its range of usefulness in confined places, narrow streets and when reversing.

The front and rear wheels are interchangeable, which facilitates maintenance and service.

Despite the heavy loads which can be carried, the road-riding abilities vehicle enable a e ena

of this veh compara

tively high mean speed to be attained, and the ton-mileage figures per gallon of fuel ' have proved to be excellent.

An outstanding feature is that the loading height is only 3 ft. 1 in. To provide the largest loading space possible, the driver is seated alongside the engine, and there is a straight length of 21 ft. 6 ins. of frame behind the cab. This and other important dimensions are given at the end of the article.

It is not intended that such a vehicle as this should be used for cross-country or passenger work. It is purely a goods carrier for ordinary roads, and should make a strong appeal to railway companies and others who have to deliver heavy loads in bulk. Its cost is actually much less than would be possible in the case of a rigid six-wheeler driv

jag on all four rear wheels, so that it affords many advantages without excessive outlay.

The engine employed is a fourcylindered model of 4i ins, bore and 6 ins. stroke, developing 50 b.h.p. at 1,000 r.p.m. and having a detachable_ head. Lubrication is effected through a drilled crankshaft, the oil being supplied under pressure by a submerged pump of the gear type. All subsidiary lubrication throughout the chassis is by the Tecalewit grease-gun system. Easily removable covers are provided for the valve gear and the valves are all at the left side. Ignition is effected by a high-tension magneto driven through a flexible coupling and having variable timing, whilst carburation is attended to by

a Solex instrument, the mixture being heated by jacketing the inlet pipe with hot water. A centrifugal pump is employed for circulating the cooling water, which passes through a gilled-tube radiator of the built-up pattern. The power from the engine is conveyed through a cone clutch provided with an adjusting device, the cone being faced with Ferodo and

entirely enclosed. A clutch stop facilitates gear changing. The gearbox provides four speeds forward and a reverse, direct drive being on top gear. The ratios and the corresponding road speeds at 1,000 r.p.m. of the engine are:— Top, 7.86 to 1 (15.6 m.p.h.) ; third, 13.6 to 1 (9 m.p.h.) ; second, 21.8 to 1 (5.2 m.p.h.) ; first, 38.4 to 1 (3.2 m.p.h.) ; reverse, 49 to 1 (2.6 m.p.h.);

In many respects the design of the whole vehicle, apart from the rearmost wheels, follows normal Leyland practice; for instance, the driving axle is of the double-reduction type, with the. differential gear mounted

on the bevel-wheel shaft in front of the axle, the final reduction being through spur gears, whilst the large. inspection cover enables the': whole of the gear to be removed Without disturbing the rest of. the axle.. The' torque and driving stresses are taken. through the usual tubular torque member surrounding the propeller shaft and ending in a ball supported by a ball socket on the frame: .

Two independent brakes are. employed. One,' of theexternal-contrading type and controlled by foot, nets on a drum mounted on the gear. shall; the .other,. operated by hand,. . expands shoes in drums mounted on the two driving Wheels. No 'brakes are employed on the rearmost wheels.

The frame is of exceptional strength, the side-members having a maximum depth of 8i ins, and a width of 21 ins., whilst strong crossmembers of high-carbon steel are provided.

The road wheels are of cast-steel With tubular spokes and are all mounted on Timlfen taper-roller bearings. The tyre. equipment is 180 nun. for 850 mm. rim, singles for the first and third axles, and 180 mm. for 850 mm. twins for the driving wheels. •

The petrol tank is situated. 'under . the driver's seat and has a capacity of 27 gallons; fuel is fed-to the. carburetter by gravity.

The main dimensions are:— Wheelbase (front axle to driving axle). 1.4 ft. 41-4-g ins.; driving axle to third axle, 4 ft. di ins.; front

track, 5 ft. 8 ins.; driving-axle track, 5 ft. 11 ins.; track of third axle, 5 ft. 8i ins.; overall width, 6 -ft. 11 ins.; overall length, 27 ft.; length of frame behind cab, 21 ft. 6 •ins.; width of frame, 3 ft. 7 ins.;

turning circle, 62 ft. 3 ins. The weights of the vehicle unladen, but complete with cab and body, are:— Front s.xle, 2 Ions 4 cwt. 2, qrs.; centre axle, 2 toes' ewt. 2 qrs.; rear-axle,1 ton 2 'qrs., making a total of 5 tops •13 cwt. 2 qrs. The corresponding weights when the vehicle is, carrying its full load are :—Front axle, 4 tons 1 cwt.

2 qrs.; centre axle, 7 tons 11 cwt.

3 qrs.; rear axle, 4 tons 2 cwt. 1 qr.; total, 15 tons 15 cwt. 2 qrs. The net chassis weight is 5 tons 10 cwt., which is light considering the load.