• Brewing and soft drinks companies have traditionally lead from

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

the front in the design of truck bodies — particularly where high street delivery Vehicles are concerned.

Some pursue extraordinary concepts such as Scottish and Newcastle's Bruce Mk2 Freighter-based joint project with Leyland Daf. This strange beast achieves a knee-height load-bed thanks to its backto-front engine layout which drives the front wheels.

Many use the engineering skills of established chassis converters, such as Chassis Developments or York Transport Engineering, to lower the vehicle frame before having a body built on to it. Others have even convinced truck manufacturers such as Leyland Daf 4cid Seddon Atkinson of the value in 'altering the frame "inhouse", while ERF has taken the -ultimate step in having chassis rails pressed into a "dropped" profile.

One major drinks producer, Sheptsm Mallet-based Showerings, which is part of the Allied Lyons group and famous for its Babycham and Coates Gaymer cider, runs a predominantly Seddon Atkinson fleet.

It comprises 38-tonners for long-haul work to distant parts of the UK and the Irish Republic and two-axled 16/17-tonne rigids for medium and short distance deliveries to High Street outlets.

By last year, Showerings harbegun to replace its time-expired 200-series rigid Seddon Atkinsons with Phaser-engined 211s converted to a drop-frame design by its own engineering arm, Tachograph Services with nearby Taylor Bros of Keynsham providing the body.

After taking the first batch of eight, Showerings concluded that it would be more cost-effective for Seddon Atkinson to build the chassis-cab in-house at its Woodstock Factory in Oldham.

Using its own truck-building expertise. SA improved the design still further. It has already built 16 with 'several more .drop-frame orders "in the pipeline".

The production of such a chassis is, of course, volume-related. 'When siifficient numbers justify it, it can he is absorbed into the factory flow-line..

The 2-11 drop-frames are based on an extended 5.82m wheelbase chassis and supplied with a standard day czb, leaving any stretching to sleeper length to the bodybuilder.

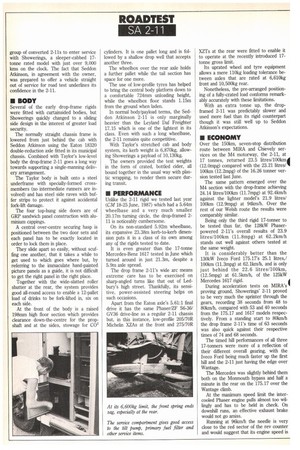

We have tested one of the most recent. group of converted 2-11s to enter service with Showerings, a sleeper-cabbed 17tonne rated model with just over 9,000 knis on the clock. The fact that Seddon Atkinson, in agreement with the owner, was prepared to offer a vehicle straight out of service for road test underlines its confidence in the 2-11.

• BODY

Several of the early drop-frame rigids were fitted with curtainsided bodies, but Showerings quickly changed to a sliding side design in the interest of greater load security.

The normally straight chassis frame is lowered from just behind the cab with Seddon Atkinson using the Eaton 18320 double-reduction axle fitted in its municipal chassis. Combined with Taylor's low-level body the drop-frame 2-11 goes a long way towards supporting a single-manning delivery arrangement.

The Taylor body is built onto a steel underframe with specially-formed crossmembers (no intermediate runners are involved) and has steel side raves with buffer strips to protect it against accidental fork-lift damage.

The four top-hung side doors are of GRP sandwich panel construction with aluminium cappings.

A central over-centre securing hasp is positioned between the two door sets and each panel has to be exactly located in order to lock them in place.

They slide apart so easily, without scuffing one another, that it takes a while to get used to which goes where but, by referring to the immaculate hand-painted picture panels as a guide, it is not difficult to get the right panel in the right place.

Together with the wide-slatted roller shutter at the rear, the system provides good all-round access to enable a 12-pallet load of drinks to be fork-lifted in, six on each side.

At the front of the body is a raised 198mm high floor section which provides clearance down-the-centre for the propshaft and at the sides, stowage for CO2 cylinders. It is one pallet long and is followed by a shallow drop well that accepts another three.

The wheelbox over the rear axle holds a further pallet while the tail section has space for one more.

The use of low-profile tyres has helped to bring the central body platform down to a comfortable 724mm unloading height, while the wheelbox floor stands 1.15m from the ground when laden.

In normal body/payload terms, the Seddon Atkinson 2-11 is only marginally heavier than the Leyland Daf Freighter 17.15 which is one of the lightest in its class. Even with such a long wheelbase, the 2-11 remains quite competitive.

With Taylor's stretched cab and body system, its kerb weight is 6,870kg, allowing Showerings a payload of 10,130kg.

The owners provided the test weights in the form of crated, bottled cider, all bound together in the usual way with plastic wrapping, to render them secure during transit.

• PERFORMANCE

Unlike the 2-11 rigid we tested last year (CM 18-25 June, 1987) which had a 5.64m wheelbase and a very much smaller 20.17m turning circle, the drop-framed 211 is noticeably cumbersome.

On its non-standard 5.92m wheelbase, its expansive 23.38m kerb-to-kerb dimension puts it in a class of its own among any of the rigids tested to date.

It is even greater than the 17-tonne Mercedes-Benz 1617 tested in June which turned around in just 21.3m, despite a 5.9m axle spread.

The drop frame 2-11's wide arc means extreme care has to be exercised on sharp-angled turns like that out of Ledbury's high street. Thankfully, its sensitive, power-assisted steering helps on such occasions.

Apart from the Eaton axle's 5.61:1 final drive it has the same Phaser/ZF S6-36/ GV36 drive-line as a regular 2-11 chassis but, in this instance, low-profile 205/70R Michelin XZAs at the front and 275/70R XZTs at the rear were fitted to enable it to operate at the recently introduced 17tonne gross limit.

Its uprated wheel and tyre equipment allows a mere 110kg loading tolerance between axles that are rated at 6,610kg front and 10,500kg rear.

Nonetheless, the pre-arranged positioning of a fully-crated load conforms remarkably accurately with these limitations.

With an extra tonne up, the dropframed 2-11 was predictably slower and used more fuel than its rigid counterpart though it was still well up to Seddon Atkinson's expectations.

• ECONOMY

Over the 1501cm, seven-stop distribution route between MIRA and Chievely services on the M4 motorway, the 2-11, at 17 tonnes, returned 23.5 litres/1001m (12.0mpg) compared with the 23.21 litres/1 100km (12.2mpg) of the 16.26 tonner version tested last June.

The same pattern emerged over the M4 section with the drop-frame achieving 24A4 litres/100km (11.7mpg) at 92.41crn/h against the lighter model's 21.9 litres/ 1001un (12.9mpg) at 941cm/h. Over the rest of our Welsh route the results were comparably similar.

Being only the third rigid 17-tonner to be tested thus far, the 128kW Phaserpowered 2-11's overall results of 23.9 litres/100km (11.8mpg) at 62.2km/h stands out well against others tested at the same weight.

It is considerably better than the 130kW Iveco Ford 175.17's 25.1 litres,/ 1001cm (11.3mpg) at 62.11cm/b, and is only just behind the 22.6 litres/100km, (12.5mpg) at 61.51cm/h, of the 125kW Mercedes 1617 rigid.

During acceleration tests on MIRA's proving ground, Showerings' 2-11 proved to be very much the sprinter through the gears, recording 38 seconds from 48 to 80Iun/h, compared with 53 and 40 seconds from the 175.17 and 1617 models respectively. From a standing start to 801cm/h the drop frame 2-11's time of 63 seconds was also quick against their respective times of 74 and 68 seconds.

The timed hill performances of all three 17-tonners were more of a reflection of their different overall gearing, with the Iveco Ford being much faster up the first hill and the 2-11 just having the edge over Wantage.

The Mercedes was slightly behind them both on the Monmouth bypass and half a minute in the rear on the 175.17 over the Wantage climb.

At the maximum speed limit the intercooled Phaser engine pulls almost too willingly and has to be held in check. On downhill runs, an effective exhaust brake would not go amiss.

Running at 96km/h the needle is very close to the red sector of the rev counter and would suggest that its engine speed is too high. Equally, it might deter the uninitiated driver from red lining it on empty return journeys.

Despite not having anti-roll bars, the 2-11's high centre of gravity load in its low-height body did not produce many adverse affects. In general it handled well, particularly around the twisting and uneven surfaced A-roads west of Witney.

On sharp left hand bends, however, it had to be slowed down more than normal to prevent what appeared to be the body rubbing against the tyres and causing smoke to emanate from underneath.

According to Tachograph Services, it is a phenomenon that is not unknown to Seddon Atkinson which recommends fitting a packing piece under the rear springs and the removal of some metal from the rear of the chassis rail in the vicinity of the helper spring leaf.

Vehicles in the Showerings fleet that are affected, are currently being modified in the TS workshops.

There was, however, nothing amiss with the brakes which were well-balanced and responsive, as the rolling road tests indicated. The park brake also held convincingly on the 25% test gradient, in either direction.

One worry for Showerings was a persistent air leak in the braking system, which in less than two hours had drained the reservoirs connected to number three gauge on the instrument panel. The leak, which lasted for several minutes and cost fuel to recharge the system, could just be heard issuing from under the cab on the driver's side, with the engine stopped.

With such a relatively low reading on the odometer, the "notchiness" of the gearbox could be forgiven, but not the unnecessarily high clutch pedal which was set very awkwardly at a mid-shin level.

• CAB COMFORT

For anyone of an average height, with the air-suspended seat positioned accordingly, the driver would need the leg fitness of a marathon runner, coupled to the fancy footwork of Michael Jackson when driving. in busy, city centre stop-go traffic.

Despite the 2-11 cab's future being controlled by the Enasa Cabtec programme it remains comfortable, yet practical and (apart from the roof ventilator) is none the worse for bodybuilders Taylor's sleepercab conversion.

It is well trimmed in the same oatmealcoloured material and has a fairly wide, single bunk with storage space beneath it.

All in all, it provides a roomy environment to work in, with a reasonable level of cross-cab access, instrumentation and driving visibility.

As usual, less important aspects tend to distract the driver's attention as it turned out: the very stiff window winder on the off-side (the passenger's side is electric), the annoying eye-level window frame and the heater fan which despite making a lot of noise was quite ineffective.

• SUMMARY

While the two-aided rigid sector of the commercial vehicle market commands high volumes, the drop-frame element, which is also used mainly for high street deliveries by brewers and caterers, sells in relatively small numbers, probably fewer than two hundred per year.

Seddon Atkinson is well-positioned to cater for the needs of operators such as Showerings. Having chosen a drive-line which gives a high level of performance, its good body/payload allowance provides an attractive proposition.

With Taylor's smart and effective body system, the 2-11-based delivery truck forms an efficient distribution combination that will quickly begin to pay back the high £36,189 initial investment over the six to eight years during which the company expects to be running it.

LI by Bryan Jarvis