INGENUITY i RAILER DESIGN

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Suspension Systems Figure Prominently in the Latest Developments in the Design of Trailers and Semi-trailers

trailers developments itrailerss for road work and operation on rough ground have been of outstanding interest. The trailer that could not get into the Commercial Motor Show building and the trailer which did so. with half an inch to spare, were both new unit.s built to exacting specifications for special overseas requirements The Cranes eight-wheeled oilfields semi-trailer for the Thornycroft Mighty Antar tractor. with a width of 10 ft. 2:1 ins., was too large for the doors and passages of Earls Court; the Dyson 50-ft. 70-ton trailer, with an overall width of 9 ft. 3 ins., was manceuvred through the doors and on to the stand by means of the hand-operated steering on the rear bogie. The Dyson trailer was designed for work at the new Singapore power station.

The Cranes trailer is mounted on four axles arranged in pairs which oscillate on roller-bearing rocker beams and has a detachable swan neck that remains in unit with the tractor whcn separated from the load deck. Built-in hydraulic jacks support the front end when stationary

Urt, to 100 Tons

Apart from the main frame, all the parts of the Dyson trailer are standard components. Vehicles with loadcarrying capacities up to 100 tons and more are built from stock components and the rapidity with which specific requirements can be met is indicated by the designing and construction of the 70-tonner in under three months.

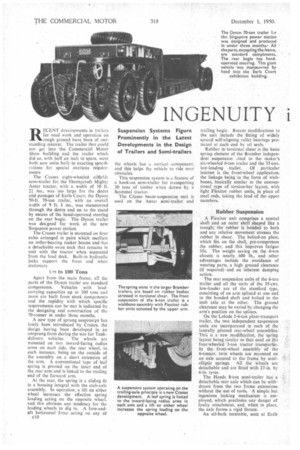

A new type of sprung suspensian has lately been introduced by Cranes, the design having been developed in an unsprung form during the war for Tankdelivery vehicles. The wheels are mounted on two inward-facing radius arms on each side, the rear wheel, in each instance, being on the outside of the assembly on a short extension of the arm. A conventional type of leaf spring is pivoted on the inner end of the rear arm and is linked to the trailing end of the forward arm.

At the rear, the spring is a sliding fit in a housing integral with the stub-axle assembly. In operation, a lift on either wheel increases the effective spring loading acting on the opposite wheel. and this obviates any tendency for the leading wheels to dig in. A fore-andaft horizontal force acting on any of c 1 0 the wheels has a .vertical component,' and this helps the vehicle to ride over obstacles.

This suspension system is ci feature of a hook-on semi-trailer for transporting 30 tons of timber %Oen drawn by a Scammel tractor.

The Cranes beam-suspension unit is used on the Antar semi-trailer and trailing bogie. Recent modifications to the unit include the fitting of widely spaced self-aligning roller bearings protected at each end by oil seals.

Rubber in torsional shear is the basic spring element of the Bramber independent suspension .1tted to the maker's six-wheeled 6-ton trailer and the 35-cwt. low-loading trailer. Of particular interest is the front.wheel application. the linkage being in the form of wishbones, basically similar to the conventional type of torsion-bar layout, with light Flexitor rubber units, in place of steel rods, taking the load of the upper metnbers.

Rubber Suspension

A Flexitor unit comprises a central shaft and an outer shell shaped like a trough; the rubber is bonded to both and any relative movement stresses the rubber in shear. The bolted-on plate, which fits on the shell, pre-compresses the rubber, and this improves fatigue life. The weight saving on the 6-ton chassis is nearly 600 lb., and other advantages include the avoidance of wearing parts, a high ground clearance (if required) and an inherent damping action.

The rear suspension units of the 6-ton trailer and all the units of the 35-cwt. low-loader are of the standard type, consisting of an arm splined at one end to the bonded shaft and bolted to the stub axle at the other. The ground clearance may be varied by changing the arm's position on the splines.

On the Lolode 5-6-ton plant-transport trailer, the two independent suspension units are incorporated in each of the laterally pivoted rear-wheel assemblies. This is a new modification, the spring layout being similar to that used on the four-wheeled 3-ton tractor transporter. In the front-wheel assembly of the 6-tonner, twin wheels are mounted on an axle secured to the frame by semielliptic springs. All the wheels are detachable and are fitted with 27-in. by 6-in. tyres.

The Hands 8-ton semi-trailer has a detachable rear axle which can be withdrawn from the two frame extensions without the use of tools. A simple but ingenious locking mechanism is employed, which precludes any danger of faulty attachment, and, when in place, the axle forms a rigid fixture.

An oil-bath turntable, seen at Earls Court, on a 4-ton cable-drum trailer, is another interesting Hands feature. The load is taken by a large machined pin, which turns in a cylinder filled with oil. The pin is cut away to increase the volume of oil and to promote continuous lubrication of the parts.

Facilities for winching the load on to the platform from behind are provided on a Hands 10-12-ton straight-framed trailer. The unit exhibited at the Show was the first of a fleet intended for oilcompany service in Sarawak.

The Carrimore retractable turntable was designed to reduce the space allowed for the relative movement of the cab and the front of the semitrailer. The towing link comprises a pin, bushed at both ends, and a sliding cross-head, by means of which the distance between the tractor cab and the semi-trailer is maintained at a minimum, whatever the angle of turn.

The Carrimore 2-3-ton tipping trailer provides a continuous ramp for loading wheeled vA:cles.

In many overseas countries the incorporation of a withdrawable-wheel

assembly in a plant trailer to provide extreme low loading is not considered necessary and the Tasker 20-ton dropframed semi-trailer was staially designed to compete with the fixedwheel American designs. With 8.25-in. by 15-in. tyres, the loading height is 3 ft., the particular tyre size being chosen because it is universally obtainable.

A feature of the Tasker 10-ton drop

framed semi-trailer is the use of a trailing axle which is removed, complete with road springs and mudguards, for end loading. Designed for carrying machinery, the trailer May be loaded from the side or end. A Tasker prototype fifth-wheel coupling, which requires a sub-frame -to suit the 'towing. vehicle, used,. is still in the development stage.

An interesting neW product of the .British Trailer CO.,' Ltd., is a 50-seater semi-trailer coach with 'an. Austin Loadstar tractor. *Fitted with the B.T.C. S.A.E.coupling, the semi-trailer may be used with any' type of tractor

and the prefabricated, coach is,deaigned to reduce to_a minimum landed costs in overseas ports. The semi-trailer incorPorates. the B.T.C.' TwinsPring suspension system, with an upper and lower leaf spring on each .side of the axles, which is particularly suitable for high-speed running over bad road surfaces.

The latest lVfultiwheeler 6-ton semitrailer of all-steel construction has a

main platform with fittings designed to acconinaodate large crates of glass in a vertical position. Four &mountable vertical stanchions are adjustable for height by means of a screw, and may be ,.stowed on the top ',platform when not in use.

For, the 'past 12 Months, the 'Eagle. Engineering Co.,Lid.. Warwick, has been using an Austin short-Wheelbase vehicle alternately as -a 5-ton tipper and as a tractor with-a semi-ttailer: -Easy conversion h-as made. it possible to run one vehicle in place of two on mixed transport Work, thereby .yielding a--big saving in overall running costs.

The tipping body is hued with deep mounting brackets and is installed on the prime mover with the trailer rocking-carriage in position, the tipping !am being tied to the back of the cab.

The use of a four-legged sling attached to the lifting lugs enables the body to be handled by a hoist, and the conversion is completed by two men in about 10 minutes. If a hoist be not available, the body may be fitted or removed with the help of barrels.

The semi-trailer is a standard Eagle 6-8-ton unit with a welded channelsection chassis and a deep-sided body with oak framing.

Manufacturers mentioned in this article arc: Cranes (Dereham). Ltd., Ilereham; R. A. Dyson and Co., Ltd., Grafton Street, Liverpool: Bramber Engineering Co.. Ltd.. 'Waterloo Road, London, N.W.2: Low Loading Trailer Co. Ltd.. Goldington Road. Bedford; Harids (Letchworth), Ltd.. Icknield Way. Letchworth; Carrimore Six Wheelers, Ltd.. Great North Road, London, N.12; Taskers of Andover (1932), Ltd.. Andover: British Trailer Co., Ltd., Farm Lane, London, s.w.6; Multiwheelers (Commercial Vehicles), Ltd., Rogeth Green Avenue, South Harrow; Eagle Engineering Co.. Ltd.. Wa nvick.