A MISCELLANY OF IDEAS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Suggestions by Our Driver and Mechanic Readers.

TN order to grind the interior working ifaces of brake drums " J.A.W.," of Londonderry, constructed a special device. The main part consisted of an engine stand, the bearers being removed, and used along with the adjustable bar to hold the two ends in position. Three feet of 11-in. shafting was passed through the bearings on top of the stand, carrying two cast-iron bushes turned so as to be a firm fit in the hub of the wheel to be dealt with.

Two wooden bearers for the grindingwheel spindle were made out of oak, 31 ins. by 2 ins., and hinged at one end. To keep the bearers parallel, the free ends were bolted to a piece of 14-in. hard wood, about 10 ins, wide, which rested upon a strong spiral spring supported on a plank passing across the stand. This spring tended to force the grinding spindle upwards, therefore a bolt was passed through its centre, and a wingnut provided the means of adjustment, thus giving a vertical feed for the grinding wheel.

The grinding spindle was made from a piece of Ford shafting, the bearings being two front-spring leaves which had broken off in service. An ordinary flat belt drove the srAndle, and the road wheel under treatment was revolved by hand, being fed horizontally at the same time.

This week's prize of 15s. is awarded to "J'.A.W." for his contribution, OWING to the inconvenient angle of the filler neck of some petrol tanks a certain amount of fuel is lost when filling from a pump. "II.H.B.," of Rothrham, experienced considerable difficulty in this connection, and suggests tha_ his idea may be of use to other drivers.

A flexible tube of 2 ins, bore is taken and the end which is intended to go into the petre tank filling orifice has a small piece of brass tube of approximately g in. diameter fastened on to the outside to act as an air vent. The opposite end of the flexible pipe has a rubber washer inserted. The internal diameter of this washer is of such a size that the tube will fit the majority of nozzles on the filling-pump hose. By fixing the device on to the nozzle and inserting the flexible tube into the tank, splashing and consequent waste will be avoided. The diameter of the flexible tube, of course, should be selected in accordance with the size of the petrol tank filler.

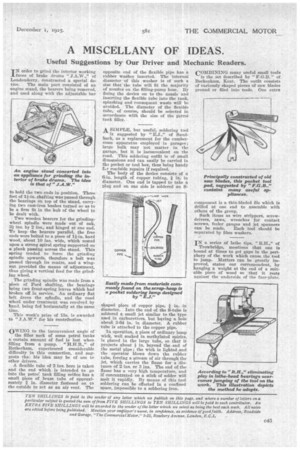

A SIMPLE, but useful, soldering tool

is suggested by " E.J.," of Sandbaeh, as a replacement for the cumbersome apparatus employed in garages ; large bulk may not matter in the garage, but it is inconvenient on the road. This soldering outfit is of small dimensions and can easily be carried in ths pocket or tool box, thus being handy f,,r roadside repairs if required.

The body of the device consists of a 6-in, length of copper tubing, g in. in diameter. One end is tapped to take a plug and on one side is soldered an 5 shaped piece of copper pipe, 4 in. in diameter. Into the end of the S-tube is soldered a small jet similar to the type used in carburetters, but having a hole about\ 3-64 in. in diameter. A rubber tube is attached to the copper pipe.

In operation, a piece of ordinary lamp wick, well soaked in methylated spirits, is placed in the large tube, so that it projects about 4 in. beyond the end of the metal pipe; the wick is lighted and the operator blows down the rubber tube, forcing a stream of air through the jet, which carries the flame for a distance of 2 ins. or 3 ins. The end of the flame has a very high temperature, and if concentrated on a stick of solder will melt it rapidly. By means of this tool soldering can be effected in a confined space, impossible to a soldering iron.

COMBINING many useful small tools is the set described by " F.G.13." of Beckenham, Kent. The outfit consists of variously shaped pieces of saw blades ground or filed into tools. One extra component is a thin-bladed file which is drilled at one end to assemble with others of the group.

Such items as wire strippers, screwdrivers, saws, wrenches for contact screws, feeler gauges and jet spanners can be made. Each tool should be separated by fibre washers.

IN a series of lathe tips, " of Trowbridge, mentions that one is bound at times to get gaps in the periphery of the work which cause the tool to jump. Matters can be greatly improved, states our correspondent, by hanging a weight at the end of a suitable piece of wood so that it rests against the underside of the face-plate.