Competitive Price and Performance

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

By

John F. Moon, A.M.I.R.T.E.

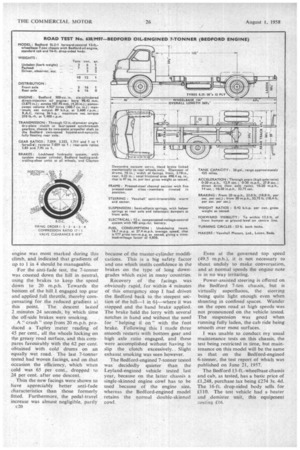

ONE of the most competitive fields in the British commercialvehicle industry is that centred around 7-ton chassis, these being considered suitable for use with payloads of up to 10 tons under favourable conditions—although not with the manufacturers' blessings, of course. The Bedford 7-tonner, with Bedford oil engine, is a worthy contestant in this struggle for the biggest share of the 7-tonner market, as its relatively low initial price, good all-round performance and well-tried basic design make it an attractive proposition to operators engaged on general haulage.

When the Bedford 300-cu.-in. oil engine was introduced early last year, it was offered in chassis of up to 6 tons nominal capacity only, although it was a reasonably safe bet that Vauxhall Motors, Ltd., would sooner or later fit it to their 7-ton models. Wisely enough, this was not done until thorough proving had shown it to be wholly suited to the extra loading, and even now it is offered only in conjunction with the new Bedford two-speed axle.

The combination of the flexible Bedford engine and what amounts to eight transmission ratios ensures a gear and a speed for almost all likely operating conditions, thus enabling high-speed schedules to be maintained without excessive fuel cost. Another important factor is the driver's aspect: in this respect also the Bedford is good, the engine being quiet and a good "slogger," both the gearbox and axle changes being light and simple, whilst the brakes are lighter to use and less prone to fade than on earlier 7-tonners, Basically the latest Bedford 7-tonner is little changed from the familiar S-type Big Bedfords introduced some eight years ago, apart from the use of c18 the new engine and rear axle. The 89 b.h.p. (net) oil engine is unitmounted with the standard Bedford four-speed synchromesh gearbox and the mounting layout is the same as that used when the alternative 114 b.h.p. (net) petrol engine is fitted. The other power unit option is the Leyland 0.350 oil engine, an example of which was tested and reported on on September 20, 1957.

The Bedford two-speed axle follows American General Motors' practice, and is a hypoid-bevel unit with epicyclic secondary-reduction gears, engagement of these being by dog clutch. Changes are made through a manual control which actuates a vacuum valve, and there is negligible delay in operation. The standard axle ratios are 5.83 and 7.95 to 1, but alternative gearing giving 6.40 and 8.72 to 1 can be specified for heavyduty operation, such as articulated or tipper work.

Extensive braking system modifications have been carried out since The Commercial Motor's last test of a Bedford 7-ton chassis. Moulded facings are standard, of course, as on all other Bedford vehicles, but other improvements include the use of a larger Clayton Dewandre vacuum servo, and bisector units with increased wedge angles. at the rear axle, these combining to give a higher proportion of braking on the front wheels. The stroke of the front-brake piston in the tandem master cylinder has been increased to allow greater front drum expansion before the piston bottoms, and hence greater safety on long down grades. The brake-pedal length has been increased to compensate for the

greater travel of the front-brake piston, and whilst this has not reduced the normal brake pedal travel, it gives a greater travel margin under fade conditions, minimizing the chance of the pedal's .touching the floorboards on such occasions.

A 13-ft.-wheelbase model was offered for test, this having a standard 16-ft. drop-sided timber body which brought the kerb weight up to 3 tons 61 cwt. Concrete blocks, weighing 7 tons 21 cwt., comprised the test load.

Weather conditions could hardly have been worse considering the time of the year, the rain falling continuously throughout the test and flooding occurring in many parts of south-east England the . same. day. Braking tests were out of the question, therefore, and had to be postponed until a later date. A check stop was made from 20 m.p.h., however, and the stopping distance was 25.5 ft., the front wheels locking but no dangerous skidding occurring. A hand-brake stop from 20 m.p.h. produced a Tapley meter figure of 29.5 per cent.

Repeat tests made on dry roads showed the braking efficiency to be high. When braking from both 20 and 30 m.p.h. none of the wheels locked, although the heavy marks on the road left by the front wheels indicated that they were on the point of so doing---an ideal condition. The figures obtained were better than average for this class of vehicle, which is particularly commendable in view of the simplicity of the braking system. The hand brake also was better than might be expected, 32 per cent. being recorded from 20 m.p.h.

Fuel-Consumption tests were made along the usual 6-mile undulating route between Barton and Clophill, on the A6 road. Several runs were made in very heavy rain, consumption rates of 16.4 m.p.g. being returned when I " drove and 15.7 m.p.g. in heavy traffic conditions when Vauxhall's Guy Tidbury drove. A third test was then made on almost dry roads, and on this occasion a figure of 16.7 m.p,g, was recorded. The average speed of 27.4 m.p.h. was almost the same as on the two previous runs, the maximum speed being kept at 35 m.p.h. wherever possible. Normal main-road traffic was encountered on the third test.

Throughout each run high axle ratio was used for most of the time, split shifting being employed only when ascending the hill to the south of Clophill and when turning at the halfway triangle. As has been shown before, this route gives fully representative fuel figures for normal working throughout Britain, although in very flat country the two-speed axle will give an added advantage and figures apprOaching 18 m.p.g. might be expected under favourable conditions. with at least 26 m.p.g. when unladen.

A series of acceleration tests was made using high, low, and a combinartion of axle ratios, and the best figures were obtained using high ratio and firSt, second and third gears when accelerating from 0-30 m.p.h., and low axle when making the direct-drive tests. Surprisingly good figures were recorded in both cases, and they serve to illustrate not only the good flexibility of the power unit, but also that there is ample power on hand to enable high average speeds to be main tained on long runs. . .

The +-mile ascent of Bison Hill, adjacent to Whipsnade Zoo, was used for the hill-climb and brake-fade tests, the average gradient of this hill being 1 in 101. The ambient temperature was 53 F., and the engine coolant was at 157. E. before making the climb. The ascent lasted only 4 minutes 40 seconds, and the lowest gear usedfirst-high — was engaged for 56 seconds, the minimum road speed being 8 m.p.h.

A temperature rise of only 7° F. was recorded, showing generous latitude in the cooling system, which is pressurized to raise the boiling point well beyond any temperature likely to be attained. in service. The pulling power of

engine was most marked during this climb, and indicated that gradients of up to I in 4 should be manageable.

For the anti-fade test, the 7-tonner was coasted down the hill in neutral, using th.e brakes to keep the speed down to 20 m.p.h.. Towards the bottom of the hill I engaged top gear and applied full throttle, thereby compensating for the .reduced gradient at this point. The descent lasted 2 minutes 24 seconds, by which time the off-side brakes were smoking.

A !` crash" stop from 20 m.p.h. produced a Tapley meter reading of 45 per cent., all the wheels locking on the greasy road surface, and this compares favourably with the 62 per cent. obtained with cold drums on an equally wet road. The last 7-tc+nner tested had woven facings, an.d on -that occasion the efficiency, which when cold was 65 per cent., dropped to 24 per cent. after one descent.

Thus the new facings were shown to have appreciably better anti-fade characteristics than those formerly fitted. Furthermore, the pedal-travel increase was almost negligible, partly • c20 because of the master-cylinder modifications. This is a big safety factor and one which instils confidence in the brakes on the type of long downgrades which exist in many countries.

Recovery of the facings was obviously rapid, for within 4 minutes of this emergency stop I had driven the Bedford back to the steepest section of the hill-1 in 64—where it was stopped and the hand brake applied: The brake held the lorry with several notches in hand and without the need for " helping it on" with the foot brake. Following this I made three smooth. restarts with bottom gear and high axle ratio engaged, and these were accomplished without having to slip the clutch excessively.. Slight exhaust smoking was seen however.

The Bedford-engined 7-tonner tested was decidedly quieter than the Leyland-engined vehicle tested last year, because on the latter chassis a single-skinned engine cowl has to be used because of the engine size, whereas the Bedford-engined model retains the normal double-skinned cowl.

Even at the governed top speed (49.5 m.p.h.), it is not necessary to shout unduly to make conversation, and at normal speeds the engine note is in no way irritating.

Power-assisted steering is offered on the Bedford 7-ton chat,sis, but is virtually _superfluous, the steering being quite light enough even when shunting in confined spaces. Wander on the open road at high speedswas not pronounced on the vehicle tested. The suspension was good when running fully laden, the cab ride being smooth over most surfaces.

I was unable to conduct my usual maintenance tests on this chassis, the test being restricted in time, but maintenance on this model will be the same as that on the Bedford-engined 6-tonner, the test report of which was published on June 21,.1957.

The Bedford 13-ft.-wheelbase chassis and cab, as tested, has a basic price of £1,248, purchase fax being £274 3s. 4d. The 16-ft. drop-sided body sells for £110. The test vehicle had a heater and demister unit, this equipment costing £16,