OPINIONS FROM OTHERS.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

The Editor invites correspondence on all subjects connected with the use of commercial motors. Letters &Ponta oe On One side of the paper only and typewritten by preference, The right of abbreviation is reserved, and no responsibility for views expressed is accepted.

The T-headed Bolt Belt Fastener.

The Editor, THE, COMMERCIAL MOTOR.

[1981] Sir,—In your isaue of July 18th you illustrated a belt connector which has been sent along to you by "A.T.G.," of Musselburgh r Roadside and Garage" feature..—En., Calf.1 it may interest your readers to know that this exact form of belt connector was brought out by the Albion Motor Car Co., Ltd., a couple of years ago, and has been used by them as standard since. A row of holes a5a in. apart are pierced in the belt to begin -kith, so that when adjustment is required it is only necessary to take up the belt another hole and cut off the projecting flap.

So far as we are aware, this belt connector was invented and introduced by us. The " T " head of the bolt effectively 'prevents the bolt from turning,. and the. nut is of the same oblong shape.—Yours faithfully, ALBION MOTOR CAR. CO., LTD.,

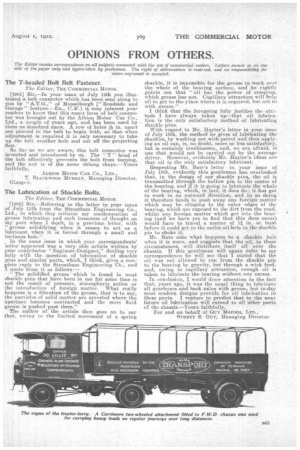

The Lubrication of Shackle Bolts.

The Editor, THE COMMERCIAL MOTOR.

11.952] Sir,-Ileferring to the letter in your is-sue of July 11th from the Streatham Engineering Co., Ltd., in which they criticise my condemnation of grease lubrication and such looseness of thought on my part when I dealt, in a previous letter, with " grease solidifying when it ceases to act as a lubricant when it is forced through a small and tortuous hole."

In the same issue in which your correspondents'. letter appeared was a very able article written by your contributor " Engineer-Designer.," dealing very fully with the question of lubrication of shackle pins and similar parts, which, I think, gives a complete reply to the Streatham Engineering Co., and I quote from it as follows The solidified grease which is found in most shackle pins that have been in use for some time is not the result of pressure, atmospheric action or the introduction of foreign matter. What really happens is a filtration of the grease, that is to say, the particles of solid matter are arrested where theaperture becomes contracted and the more fluid grease is pushed past them."

The author of the article then goes on to say that. owing to the limited movement of a spring shackle, it is impossible for the grease to work over the whole of the bearing surface, and he rightly points out that " oil has the Power of creeping, which grease has not. Capillary attraction will help oil to get to the place where it is required, but not so with grease."

I think that the foregoing fully justifies the -attitude I have always taken up—that oil lubrication is the only satisfactory method of lubricating shackle pins.

With regard to Mr. Hayter's Letter in your issue of July 18th, the method he gives of lubricating the shackles, by washing out with petrol and then applying an oil can, is, no doubt, more or less satisfactory, but is certainly troublesome, and, we are afraid, is one that would not he carried out by the average driverHowever, evidently Mr. .FIa.ythr's ideas are that oil is the only satisfactory lubricant.

Respecting Mr. Bate's letter in your issue of July 18th, evidently this gentleman has overlooked that, in the design of our shackle pins, the oil is transmitted through the hollow pin to the centre of the bearing, and if it is going to lubricate the whole of the bearing, which, in fact, it does do; it has got to work in an outward direction, and in so doing it therefore tends to push away any foreign matter which may be clinging to the outer edges of the bearing, which are exposed to the dirt from the road, whilst any foreign matter which got into the bearing (and we have yet, to find that this does occur) would have tu. travel a matter of 1i in.. at least before it could get to the outlet oil hole in the shackle pin to choke it.

Mr. Bate asks what happens to a shackle bolt when it is worn, and suggests that the oil, in these circumstances, will distribute itself all over the chassis. If this gentleman will again refer to my correspondence he will see that I stated that the oil was not allowed to run from the shackle pin to the bearing by gravity, but through a wick feed, and, Owing to capillary attraction, enough oil is taken to lubricate the bearing without any excess.

In conclusion, I would draw attention to the fact that, years ago, it was the usual thing to lubricate all gearboxes and back axles with grease, but to-day most modern designs provide for oil lubrication to these parts. I venture to predict thatin the near future oil lubrication will extend to all other parts of the chassis.—Yours faithfully,

For and on behalf of Guy MOTORS, LTD.,

SYDNEY S. GUY, Managing Director.