SPECIFICATION OF W.O. VEHICLE.

Page 18

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

The Army Calls for a 30-cwt. Vehicle Designed to Run on Pneumatic Tyres, and Built to Conform to Certain Requirements which are Epitomized,Below.

Four-cylinder vertical engine, minimum bore 100 mm., minimum R.A.C. rating 24 11.p., capable of maintaining a h.h.p. not. less than R. A.C. rating for three hours' rim at a speed equivalent to 22 m.p.h. Inlet and exhaust valves mechanically operated.' Valve stems enclosed in removable dust-proof covers. It is desirable that valves or parts of same cannot enter the cylinder if fracture occurs. If gudgeon pins work loose they must not score cylinder walls.

Provision to be made for dropping the lower half of the crankcase without disturbing the main bearings. If crankshaft runs on ball bearings, this stipulation will be waived Means of adjustment to be provided for timing chains. Test plugs to indicate high and low oil-levels and a plunger type

of lubrication indi

-cator are required, Tropical the latter to be fitted to the dash so that the driver may feel the plunger. The oil filter must be ac_ cessible' large and efficient, and its withdrawal should not involve the loss

f the main body

The engine must be in a bonnet, which must be entirely removable and must rest on angle steel or similar supports independent of the radiator. The engine must not he under the driver's seat, and the exhaust pipe should, so far as possible, pass outside the undershield.

Righ-tension magneto ignition of approved type. If automate advance is fitted, complete control should be provided for connecting it up to contact breoker of standard magneto, in case the latter should have to be fitted as a replacement. It is desired that. magneto should be as standardized in the British Engineering Standards Association's Report, No. 80, dated 1917; if not, it must be interchangeable with standard. Couplings should also be as laid down ; if not, proviaron must be made for fitting a standard coupling. The ignition timing must be clearly marked on the flywheel to a fixed pointer with stamped directions. The starting handle shoald preferably be carried on an extension of the crankcase; folding or detachable types are not desirable. The handle should be kept vertical when not in use, and renewable dogs must be fitted to both crankshaft and handle spindle.

Maximum petrol consumption, one gallon per 40 gross ton. miles, lower consumption desirable.

The engine must be efficiently cooled under all conditions, or must be capable of simple modification to enable it to function effectively in tropical climates. A pump is essential, but if it fails circulation must continue. The temperature of the cooling water must not exceed 100 degrees above

A suggested method for varying speed of fan to suit climate.

°of oil. that of the atmosphere. Provision should be made for fitting a radiator cover of the apron type for use, in cold climates.

Adequate draining of all parts must be arranged for, pre. ferably by one accessible cock not less than in: bore This cock must be so fitted as to prevent accidental opening. Provision must be made for cleaning the' cylinder water jockets and passages. An undershield held by spring clips, extending ai far back as the gearbox and provided with drain holes, must be fitted.

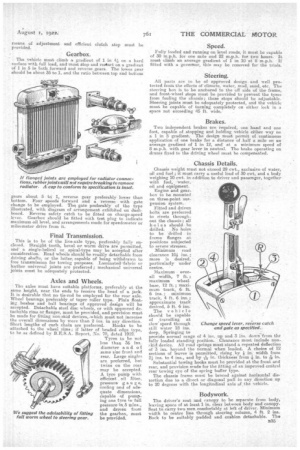

Radiator.

by flat belt. Drive to be readily accessible for repair and adjustment. Petrol Supply.

Petrol tank, minimum capacity 15 gallons. Adequate supply must be ensared to engine on all gradients up to and including 1 in 4i and any road camber. .A gravity feed with two-way cock for retaining 2i gallons is preferable. Supply cock to the carburetter to be operated from outside frame. If pressure system is used, auxiliary gravity tank to hold at least 2gallons must be fitted. In this case a cock is to be fitted on the main petrol tank and an approved pressure gauge provided. The vehicle should travel 200 miles fully loaded on its tank capacity and spare supply, the latter to be contained in two or more two-gallon tins carried in special racks provided as part of the body equipment. Tanks should be made of the following materials :—Welded steel, galvanized after making ; copper or brass, brazed and riveted and stayed at soldered joints; sheet steel tinned, if tanks of approved de sign. Lead-coated steel is not. desired. Petrol gauge of a.pproved type and adequate removable gauze filter in filler hole are necessary. Petrol tank filler to be outside frame, and means provided for cleaning tank. Filler orifice, minimum diameter 2 ins., cap of hinged type tightened by screw with no loose parts. Ariceesible fitter of approved type to be provided in supply system. Petrol must not leak on to exhaust pipe.

Clutch.

Plain cone or single disc type, with satisfactory means of lubrication to clutch spigot and withdrawal collar or thrust bearing ; to be of ample capacity and designed to facilitate gear changing, ample wearing surfaces, accessible means of adjustment and efficient, clutch stop must be provided.

Gearbox.

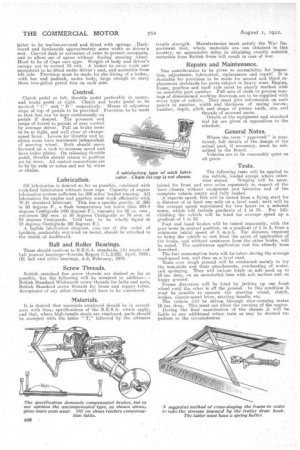

The vehicle must climb a gradient of 1 in 4+ on a hard surface with full load, and-must etop and restart on a gradient of 1 in 5 in hoth forward and reverse gears. The lower gear should be about 35 to 1, and the ratio between top and bottom gears about 5 tee 1, reverse gear preferably lower than bottom. Four speeds forward and a reverse with gate chimes to be employed. The gate preferably of the type illustrated, with diagram of areangement exhibited on dashboard. Reverse safety catch to be fitted on change-speed lever. Gearbox should be fitted with test plug to indicate maximum oil level, and arrangements made for speedometer or mileometer drive from it.

Final Transmission.

This is to be of the live-axle type, preferably fully enclosed. Straight tooth, bevel or worm drive Are permitted, and a single-Helical or spiral-type may be accepted after consideration. Road wheels should he readily detachable from driving ehafte, or the latter, capable of being withdrawn to free transmission for towing purposes. Laminated 'fabric or leather universal jointe are preferred ; mechanical universal joints must be adequately protected.

Axles and Wheels.

The axles must have suitable platforms, preferably at the same height, near, the ends to receive the head of a jack. It is desirable that no tie.rod be employed for the rear axle. Wheel bearings preferably of taper roller type. Plain floating bushes and bell bearings of approved design will be accepted. Detachable steel disc wheels or with approved detachable rims or flanges, must be provided, and provision most be made for fitting. non-skid deviees,,which must not increase the overall dimensions by more than 2 ins. in any direction.

Short lengths of curb chain are preferred. Hooks to be attached to the wheel lime; if latter of beaded edge type, to be as defined by HE.S.A. Report, No. 70, dated 1919.

Tyres to be not less than 36 ins. diameter a nd of same size front and rear. Large singles are preferred, but twins on the rear may be accepted. A tyre punip with efficient', i1 filter, pressureg au g e, cooling and of adequate dimensions, capable of pumping one tyre FAI full pressure ire5 mine., and driven from the gearbox, nnest be provided.

Speed.

. Fully loaded and running on level roads, it must be capable of 30 m.p.h. for one mile and 22 m.p.h. for two houre. It must climb an average gradient of 1 in 10 at 8 m.p.h. If fitted with a governor, this may be removed for the trials,

Steering.

All parts are to be of approved design and well protected from the effects of climate, water, mud, sand, etc. The steer-big box is to be anchored to the off side of the frame, and front-wheel stops most be provided to prevent the tyres from fouling the chaesis; these stops should be adjustable. Steering joints must be adequately protected, and the vehicle must be capable of turning completely on either lock in a space not exceeding 45 ft. wide.

Brakes.

Two independent brakes are required, one hand and one foot, capable of stepping and holding vehicle either way on a 1 in 5 gradient. The design must permit of -continuous application of one brake for a distance of half a mile on an average gradient of 1 in 12, and at e minimum speed of 8 m.p.h. with gear lever in neutral. The brake operating on drums fixed to the driving wheel must be compensated.

Chassis Details.

Chassis weight must not exceed 29 cwt., exclusive of water, oil and fuel ; it must carry a useful load of 30 cwt, and a body weighing 10 cwt. in addition to driver and passenger, together with fuel, Water, oil and equipment.

Enginie and gearbox to be mounted on three-point suspension system.

Fitted and driven bolts are preferred to rivets throughout the chassis; all holes should be drilled. No holes to be drilled in frame flanges at positions subjected to severe stresses.

Minimum road clearance 10+ ins.; more is desired; particularly under centre.

;Maximum overall width, 7 ft.; maximum wheel. base, 12 ft.; maximum track, 6 ft. 6 ins.; minimum track, 4 ft. 6 ins.e approximate track desired, 5 ft. 6 ins.

The vehicle should be capable of travelling at

slow speed through Change speed lever, reverse catch still water 18 ins and gate as specified.

deep. Springing to •

provide normal range of 4 ins, up and 3 ins. down -from the fully loaded standing position. Clearance Most include non.

skid device. All road springs must stand a repeated deflection

of 3 ins. beyond the normal when loaded. A choice of 12 sections of leaves is permitted, rieinge.loy + in. width from 2L ins. to 4 ins., and by ix,e in. thickness from A in, to le in. Substantial towing hooks must be provided at the front and rear, and provision' rrade for the fitting of an improved central rear towing eye of the spring buffer type.

The chassis frame must be braced against horizontal distortion due to a direct or diagonal pull in any direction up to 20 degrees with the longitudinal axis cif the vehicle.

Bodywork.

The driver's seat and canopy to be separate from body, leaving space of at least 1 in. clear between body and canopy. Seat to carry two men comfortably at left of driver. Minimum width to centre line through steering column, 4 ft. 2 ins. Back to be suitably padded and cushion detachable. The latter to be leather-covered and fitted with springs. ,Dashhoard and footboards approximately same width as driver's seat. Curved dash or extension of same to protect occupants, and to allow use of apron without fouling steering wheel. Hood to be of Cape cart type. Weight of body and driver's canopy not to exceed 10 cwt. A lockerto carry tools anti equipment to be fitted under driver's seat, and accessible from left side. Provision must be made for the fitting of a locker, with bar and padlock, under body, large enough to carry three two-gallon petrol tins on each side.

Control.

Clutch pedal at left, throttle pedal preferably in centre, and brake pedal at right. Clutch and brake pedal to be melted "C" and, " B" respectively. Means of adjusting slope of top of pedals to be provided. Provision to be made so that feet can be kept continuously on pedals if desired. The pressure and range of travel to permit of easy control by average driver. Pull on brake lever to be at right, and well clear of changespeed lever. Levers for throttle and ignition most have Movement independent of steering wheel. Both should move forward on a rack to increase speed and have index plates. On releasing throttle pedal, throttle should return to position set by lever. All control connections are to be by rods or tubes and not by wires or chains.

Lubrication.

Oil lubrication is desired so far as possible, combined with wick-feed lubricators without loose caps. Capacity of engine lubrication system sufficient for 200 miles' loaded running. All lubiicators for engine and gearbox must work efficiently with W.D. standard lubricant. This has a specific gravity of .895 at 60 degrees F., a flash temperature not lower than 204.4 degrees Centigrade (400 degrees F.)' viscosity for 50 cu. ems., minimum 260 secs. at 60 degrees Centigrade or 70 secs. at 99 degrees Centigrade. Cold test, to be wholly liquid at 10 degrees Centigrade (50 degrees F.).

A legible lubrication diagram, also one of the order of ignition, preferably engraved on metal, should be attached to the inside of dashboard.

Ball and Roller Bearings.

These should conform to B.E.S.A. standards, (A) single rot ball journal eReport C.L.2,582, April, 1919; (B) ball and roller bearings, A.8, February, 1919,

Screw Threads.

British standard fine screw threads are desired so far as possible, but the following will be accepted in addition:— British Standard Whitworth screw threads for bolts and nuts, British Standard screw threads for brass and copper tubes. Acceptance of any other thread will have to be considered.

Materials.

It is desired that materials employed should be in accordance with thosi specifications of the B.E.S.A. which apply, and that, where high-tensile steels are employed, parts should be stamped with the letter "T," followed by the ultimate tensile strength. Manufacturers -must satisfy the War Department that, where 'materiali are Mit obtained 'in this Country, no appreciable delay in obtaining exactly suitable materials from British firms will result in case of war,

Repairs and ,Maintenance.

Due consideration to be given to accessibility for inspea. tion, adjustment, lubrication, replacement and repair': it is desirable for provision to be made for second and third replacement standards for parts subject to heavy wear. Engine, frame, gearbox:. and back axle must be clearly marked with an 'assembly part number. Full sets of cloth or process tracings of dimensioned working drawings are to be supplied with every type of vehicle. They must give information on such points as number, width and thickness of spring leaves; number, depth, pitch and shape of pinion teeth, size and threads of screwed parts.

Details of the equipment and standard tool kit are given in appendices to the schedule.

• General Notes.

Where the term " approved" is mentioned, full details of the design of the actual part, if necessary, must be submitted to the 'Board.

Vehicles are to be reasonahly quiet on all gears.

Tests.

The following tests will 'be applied to the vehicle, loaded except where other

wise stated. Weights will he ascertained for front and rear axles separately in respect of the bare chassis without equipment and batteries and a the complete vehicle empty and fully. loaded.

A regards speed, this will be tested from a flying start for a distance of at least one mile on a level road; next will be the average speed maintained for two hours on a selected route, which will include gradients of 1 in 15. For hillclimbing the vehicle will be tried for average speed up a gradient of 1 in 10.

'Foot and hand brakes will be tested separately, with the gear lever in neutral position, on a'gradient of 1 in 5, from a minimum initial speed of 5 m.p.h. The distance reeuired to bring the vehicle to rest from the point of application of the brake, and without assistance from the other brake, will be noted. The continuous application test has already been described.

The fuel consumption tests will be taken during the average' road-speed test, and then on a level road.

Tests over rough ground will be conducted mainly to try the non-skids and their attachments, overheating of water, and springing. They will include trials on soft sand, up to 10 ins, deep, on an uninetalled lane with soft surface and on boggy ground.

Frame distortionwill be tried by jacking up one front wheel until the other is off the ground. in this condition it must be passible to operate the steering wheel, clutch, brakes, change-speed lever, starting handle, etc.

The vehicle will be driven through slow-running ;water 18 ins. deep. This must not affect the running of the engine.

During the final examination of the chassis it will be liable to any additional minor tests as may be deemed expedient in the circumstances