WHAT CONSTITUTES A PERFECT MOTORBUS?

Page 10

Page 11

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

A Summary of the Opinions of the General Manager of the Fifth Avenue Coach Co., of New York, who as a Briton was Associated with Early Bus . Developments in this Country

I N NO CITY has motorbus traffic been developed to such an extent as in London, which has virtually set the fashion, in public-passenger services to the world. The London General Omnibus Co., Ltd., is the largest organization of its kind, and the experiences of the company over a term of rears have served as an invaluable guiae to other similar, but smaller, organizations established in different parts of the world. In fact, many of those who were intimately associated with the pioneer days of bus development in this country have migrated to foreign fields, there to disseminate valuable knowledge connected with the maintenance and operation of motorbuses.

A case in point is that of Mr. G. A. Green, a Briton, whose name is known to all those associated with the early days of bus development. Mr. Green left this country some years ago and threw in his lot with the Fifth Avenue Coach Co., of New York, a company (controlled by the New York Transportation Co.) of which he is now the general manager. Mr Green has done much to bring New York's buses to their present high state of efficiency, and we may take some credit. for this, in so far as he maintains very close touch with developments in. road passenger transport vehicles in this country. We are led to write in this manner after perusal of a copy of a paper which Mr. Green read before the Society of Automotive Engineers at their recent 1326 summer meeting, and in view of the many points of technical and general interest dealt with in it, we propose making fairly extensive excerpts, feeling sure that many of our readers will be interested to make comparisons between English and American views and practices.

In its broadest sense, Mr. Green says, the Fifth Avenue Coach Co. believe the factors controlling the design of the motorbus in the order of their importance are :—(1) Safety„ (2) comfort and convenience of the public, (3) minimum operating cost. Safety easily heads the list, and a very large proportion of the engineering development, work must be concentrated under this heading..

Basic Features of Bus Design.

The design of a motorbus from a safety standpoint includes certain basic features which must be incorporated in the general constructional plan. These are :— 1. Low centre of gravity. 2. Wide frame, track and spring centres and general dimensions.

3. Effective brakes.

4. Short turning radius.

Beyond doubt, Mr. Green says, the future bus will be low hung. The inherent danger in • connection with any other form of construction is the possibility of overturning. His company have found that a safe and practical height of the frame From the ground for a singledeck bus is 25 ins, and for a double-deck

bus 18 ins. The centre of gravity of the Fifth Avenue Coach Co.'s type-L doubledeck vehicles, with a full complement of passengers on both decks, is 52 ins, from the ground. With their type-J singledeck bus this dimension is 38 ins. It is interesting to note that when rounding corners, even at a high rate of speed, skidding will occur, due to centrifugal force, but overturning is scarcely possible. Furthermore, rolling or side sway is practically eliminated.

The sectional views of the J and L type buses reproduced in Figs. 1 and 2, indicate clearly how this condition has been reached. With type L it will be seen „that the frame and rear axle construction is somewhat unconventional. The rear axle is of the internal-gear type. The spiral bevel gear and.differentiel assembly is in unit form and can be entirely assembled, and adjusted on the bench. The carrying member is a heattreated forging.

From the sectional drawing shown in Fig. 3 the general construction of the type-L axle will be clean It will be seen that the ends of the carrying member are cranked, the wheel spindles being above the drive shaft centre line. It is in this manner that the low-level construction has been accomplished. . The carrying member and driving gear assembly emphasize the general simplicity and accessibility of construction. Due to the fact that the drive shaft pinions are in the vertical plane, a special form of tooth has been developed for the internal gear to provide adequate clearance and at the same time permit of maximum silence even after a certain amount of wear has occurred.

Constructional Difficulties.

Among the constructional difficulties in connection with the production of lowlevel equipment, one of the problems is to obtain a flat floor.

In construction, wide frame, track and spring centres are features which are necessary to provide for adequate vehicular stability and, in conjunction with a low centre of gravity, make for tnaximum safety. The necessity for providing proper stability applies equally to single and double deck vehicles. It may he said that the added risk due to the top deck load with the latter is more than equalled by the higher speed of the single-deck unit. Apart from the matter of safety, a wide. frame is necessary in connection with the body construction. Obviously it is desirable to support the body as far out as possible, for in all cases the seating arrangement is such that the passengers are grouped about the outer edges. Then the wide frame admits of the lightest possible form of body underframe. The wide frame also is a factor from the standpoint of the passengers' comfort.

Mr. Green expresses the view that the overall length of a motorbus for city service should not exceed 26 ft., the total width 7 ft. 6 ins., and the overall height for single-deck vehicle 9 ft. With the double-deck bus the last-named dimension should be such that a person standing on the top deck can clear a. 14-ft. structure. With these dimensions his company have found it possible to accommodate comfortably 51 seated passengers with their double-deck and from 25 to 29 with their single-deck vehicle. Next. there is the question.of important dimensions, such as the wheelbase, other than those overall, which naturally affect the axle load distribution, the turning radius and the general comfort,

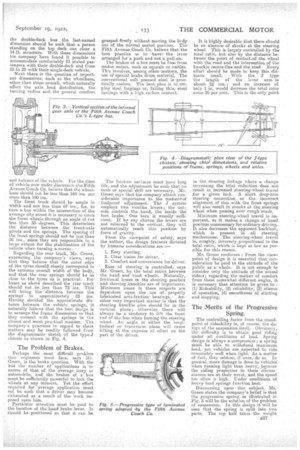

and balance of the vehicle. For the class of vehicle now under discussion the Fifth Avenue Coach Go. believe that the wheelbase should not be leas than 168 ins, nor more than 180 ins.

The front track should be ample in width and not less than 67 ins., for, to turn a bus within the intersection•of the average city street it is necessary to move the front wheels through an angle of rot less than 35 degrees. This determines the distance between the front-axle pivots and the springs. The spacing of the front springs should not be less than 36 ills., since they are responsible to a large extent for the stabilization of the vehicle when turning a corner.

Regarding the rear track, Mr. Green, expressing the company's views, says that they believe that the outer edge of the tyres should closely correspond to the extreme overall width of the body, and that the rear springs should he as close to the tyres as is practical. For buses as above described the rear track should not be less than 72 ins. This will bring the distance between the springs to approximately 52 ins. Having decided the approximate distance between the vehicle springs, it naturally follows that the best design is to arrange the framedimensions so that they -connect with the springs in the closest and most practical manner. The company's practicesin regard to these matters may be readily followed from the diagrammatic sketch of the type-J chassis as shown in Fig. 4.

The Problem of Brakes.

Perhaps the . most difficult problem that engineers must face, says Mr. Green, is the brake question. With the lana the number of applications is in excess of that of the average lorry or automobile, and the brakes of a bus must be sufficiently powerful to lock the wheels at any moment. Yet the effort required for average application must not be such that a driver may become exhausted as a result of the work imposed upon him.

Particular attention must be paid to the location of the hand brake lever, It should be positioned so that it can be grasped firmly without moving the bccly out of the normal seated position. The Fifth Avenue Coach Co. believe that the best practice is to •.have' the lever. arranged for a push and not a pull-on. The brakes of a. bus must be free from undue noises, such as squeals olarattles. This involves, among other.matters, the use of special brake drum material. The conventional soft pressed steel is practically useless. The best plan is to employ steel forgings or, failing this, steel castings with a high carbon content..

The friction surfaces must have long life, and the adjustment be such that no tools or special skill are necessary. Mr. Green says that his company attach considerable importance to the mattergof s foolproof adjustment. The j system employs two vicelike levers; the out: side controls the hand, the inside the foot brake. One 'turn is usually sufficient. If by any chance the levers are not returned to the vertical, they will automatically reach this position by force of gravity.

From the viewpoint of safety, says the author, the design features dictated by humane considerations are 1. Easy steering.

2. Clear vision for driver,

It is highly desirable that there should he an absence of shocks at the steering wheel. This is largely controlled by the total ratio, but also by the distance between the point of contact,of the wheel with the road and the intersection of the knuckle centre-line and the road Every effort should be made to keep this distance small. With the 3type the length of the lever arm is about, n ins.; and an increase of only 1 in. would decrease the total ratio some 36 per cent. This is the only point

in the. steering linkage where a change increasing the total reduction does not _ result in increased steering-wheel travel for a given lock. A short drop-arm steering connection or the incorrect alignment of this with the front springs will also result in shocks at the steering wheel when passing over rough roads.

Minimum steering-wheel travel is important, as it makes a change of hand position unnecessary for ordinary driving. It also decreases the apparent backlash, which is present in all steering mechanisms. The steering-wheel travel is, roughly, inversely proportional to the total ratio, which is kept as low as possible for this reason.

Mr. Green continues : From the viewpoint of design it is essential that consideration be paid to the attitude of the public as a whole._ It is not enough to consider only the attitude of the actual riders; regarding the matter of comfort from these somewhat different angles, it is necessary that attention be -given to : (1) Ricieability, (2) reliability, .(3) silence of operation, (4) smoothness of starting and stopping.

The Merits of the Progressive Spring.

The controlling factor from the standpoint of rideability is, of course, the design of the suspension itself. Obviously, the difficulty is to obtain' good riding under all conditions of load. Spring design is always a compromise; a spring must be able to withstand maximum load, yet vehicles are expected to ride reasonably well when light. As a matter of fact, they seldom, if ever, do so. In general, more damage is done to vehicles when running light than heavy, because the riding properties in these circumstances are at their worst, and the speed too often is high. Under conditions of heavy load springs function best.

Discoursing upon this subject, Mr. Green states the company's belief is that the progressive spring as illustrated in Fig. 5 will be the solution of the problem of suspension. In this design it will be seen that the spring is split into two parts. The top half takes the weight of vehicle body and a certain proportion of load. The bottom part or helper comes into action progressively. The top part must make a rolling contact with the bottom. One of the great advantages of this system is that, for no additional cost or weight., a marked improvement in performance is possible. The theory behind the company's choice of the progressive spring and the advantages that v be derived from its employment can readify be seen from an examination of the rear-spring deflection curve for both the progressive and the conventional semi-elliptic designs reproduced in Fig. 6. No doubt it will be appreciated that to secure comfortable riding with a small number of passengers it is necessary to have a spring of not, over 670 lb. per inch deflection. But a spring having these characteristics is not a practical arrangement, for the result Would be too great a difference in body and step height between the minimum and maximum number of passengers. This point is clearly shown in the graph, where the proportion of the

The deflection curve of a simple semielliptic spring is a straight line showing a constant load per inch. But as the progressive element comes into play gradually, a curve is apparent. The departure from a straight line (which is shown shaded) represents the load carried by the progressive element which can be designed to come into action at any desired point. It has been found most satisfactory to design this spring so that the stiffened action begins very gradually, that is,to say, after a limited number of passengers have been taken on. Obviously, as the progressive element comes into action there is a gain in the stability of the vehicle.

From the graph above referred to it is exceedingly interesting to note the change in rate of progression as a result of a variation in passenger load. The figures based on increments of 10 pass sengers given in Table 2 bring this point out in a striking manner.

For their single-deck equipment the New York company have standardized the Mack type of rubber shock insulator. This arrangement, in conjunction with the progressive system, markedly improves the riding conditions. It also avoids the necessity for lubrication and for replacement of shackles, shackle-pins and bushings; also, no spring-eyes are required,

The Question of Silence.

Mr. Green says it is a problem to produce a silent vehicle. It is doubly difficult to retain this state throughout the life of the vehicle. Silence necessitates freedom from engine vibration, quiet transmission gears, evenly stepped gears, a quiet rear end, and generally the elimination dl all rattles and squeaks from both body and chassis.

From the standpoint of silence, the Fifth Avenue Coach Co.'s greatest difficulty has been, and still is, the matter of transmission gears. They employ a four-speed gear and, three-speed chain transmission. The silent-chain transmission is particularly useful for city service where there are frequent stops and starts, and where the percentage of direct-gear operation is relatively small. Substantially it is similar to a. constantmesh gear transmission, but chains are used in place of gears. The shift is extremely short and very easy to effect. Such transmissions remain quiet throughout their useful life, and from observation it is stated that one can expect at least a year's service from the chains, which-are cheaper to replace than gears.

A Clutch with -Unconventional Features.

Of the various features that make for efficient and economical operation, the clutch is, perhaps, one of the most important. According to Mr. Green, the Fifth Avenue Coach Co. employ exclusively a clutch of the single-plate type, From Fig. 7 it will be seen that this has several unconventional features. Particular attention is drawn to the fact that the spring pressure is evenly distributed over the entire surface of the friction members by 29 small springs, the levers are balanced against centrifugal force, and the disc is exceedingly light, thus simplifying the changing of gears. Incidentally, a clutch-brake has been found unnecessary. The removal of the clutch body is an extremely simple operation, as is also the adjustment of the levers.

It is fundamentally necessary that the design of a motorbus be such that inspection and repairs can be carried out quickly and economically. It is impera-. tive, Mr. Green continues, expressing his company's views, that separate unitary construction be followed.

In connection with the matter of accessibility, Mr. Green states that it should be remembered that repairs and adjust. meats must be occasionally carried out at night, sometimes under the most unfavourable conditions. Again, assuming the use of low-level equipment, the

design should be such that inspections-, repairs and renewals can in practically all instances be undertaken from the sides or underneath the vehicles.. This means the use of pits. The practice of providing trap-doors inside buses is not desirable. Trap-doors weaken the bodies, are a possible source of accidents, cannot be kept tight in place, permit exhaust gases to leak through, and create undue noise.

The author of the paper, in dealing with the dependence of the cumulative additions or subtractions of small amounts expended on either labour or material upon the success or failure of a bus-operating concern, refers to the Fifth Avenue Coach Co.'s cost per bus for 1921 under some of the chief headings. The following figures are based on the , average of all buses in the service of the company:— Petrol ... ... $1,125.94 Lubrication ... ... 109.42 Tyres ... • ... 284.34 Repairs to chassis : Labour, 8676.97; material, $759.81 ... ... 1,436.78 Repairs to bodies : Labour, $359.00; material, $162.44 ... ..• 521.44 Drivers ... ... 3,071.71 Conductors ... ... 2,692.48

From a casual study of these data it will be seen that a relatively small percentage of saving, if applied to any of the items and then multiplied by a largo number of vehicles, must total a vast sum annually. If one assumes that the equipment in question is of goad design and that its maintenance is economically undertaken, then how much more important does this issue become when the reverse is true.

Mr. Green mentions the fact-that the Fifth Avenue Coach ,Co. exclusively employ the sleeve-valve engine for • bus work, and points to the basic advantages of this type which make for economy of operation.

The performance of a correctly designed engine is, continues the author, largely a function of its carburettor; therefore, a wide variety of results is obtainable with different settings. The points which are brought out in Inc following table are of special interest

Horse-power and Torque Data for Type J Bus.

Power developed at 1,000 r.p.m., .horse-power Power developed•per cubic inch ot displacement, horse-power .. 0.12 Weight of vehicle per horse-power, pounds Weight.of vehicle per cubic inch of displacement, pounds ... £6.2 Maximum torque, pounds-feet ... 194 Speed for maximum torque, r.p.m. .800 Decrease in torque at 400 r.p.m.,

per cent, ... 5.1 Decrease in torque at 1,400 r.p.m.,

per cent ... ... 11-9 Speed for maximum torque with a 5.4 to 1 rear-axle ratio, m.p.h.... 16.1

g01 During 1921 the entire fleet of buses of the Fifth Avenue Coach Co. averaged 50.7 ton-miles per gallon. The carbu. Aetter is of the Zenith type. Talking of tyre troubles, Mr. Green says that it is the company's practice to rentove a tyre when the rubber has kvorn

to within of the hard base.

In looking back over the records of the company, it is extremely interesting to note that in 1911 their cost per mile for tyres was 4.93 cents. From -that date a steady reduction has been effected; the figure for 1921 was 0.87 'cent per mile.

It is significant that, in concluding, Mr. Green states that, as the result of long experience in connection with the design, construction and operation of buses, his company are convinced more than ever that trucks or automobiles, modified or unmodified, are absolutely incapable of giving satisfactory and economical service if operated as buses.

We are indebted to our contemporary Automotive Industries for much of the matter and the illustrations contained in this article.