Automatic Coupling for Heavy Tractor-trailers

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

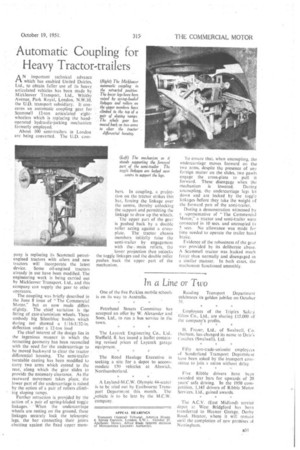

AN important technical advance which has enabled United Dairies, Ltd., to obtain fuller use of its heavy articulated vehicles has been made by Mickleover Transport, Ltd., Whitby Avenue,. Park Royal, London, N.W.10. the U.D. transport subsidiary. It concerns an automatic coupling gear for Scammell 12-ton articulated eightwheelers which is replacing the handoperated hydraulic-jacking mechanism formerly employed.

About 100 semi-trailers in London are being converted. The U.D. corn pony is replacing its Scammell petrol.engined tractors with oilers and new tractors will incorporate the latest device. Some oil-engined tractors already in use have been modified, The engineering work is being carried out by Mickleover Transport, Ltd., and this company can supply the gear to other operators.

The coupling was briefly described in the June 8 issue of "The Commercial Motor." but as now made differs slightly. The chief variation is tl)e fitting of cast-aluminium wheels. These embody big Silentbloc bushes which during test showed a 1/16-3/32-in. deflection under a I2-ton load The chief interest of the design lies in the ingenious manner in which the retracting geometry has been reconciled with the need for the undercarriage to be moved backward to clear the tractor differential housing. The semi-trailer turntable casting has been modified to carry two arms which extend to the rear, along which the Oar slides to provide the necessary clearance. As the rearward movement takes place, the lower part of the undercarriage is raised by the action of a pair of rollers climbing sloping ramps.

Further retraction is provided by the action of a pair of spring-loaded toggic linkages... When the undercarriage wheels are resting on the ground, these linkages securely lock the telescopic legs, the bar connecting their joints abutting against the fixed upper mem

hers. In coupling, a projection on the tractor strikes this bar, forcing the linkage over the centre, thereby unlocking the support and permitting the linkage to draw up the wheels.

The upper part of the gear is pushed back by a double roller acting against a crossplate. The tractor chassis members initially take the semi-trailer by engagement with the . main rollers, the lower projection then unlocks the toggle linkages and the double roller pushes back the upper part of the mechanism. To ensure that, when uncoupling, the undercarriage moves forward on the two arms, despite the presence of any foreign matter on the slides, two pawls engage the cross-plate to pull it forward. These disengage when the mechanism is lowered. During uncoupling, the undercarriage legs let down and are locked by the toggie linkages before they take the weight of the forward part of the semi-trailer.

During a demonstration witnessed by a representative of "The Commercial Motor," a tractor and semi-trailer were connected in 10 secs. and uncoupled hi 5 sees. No allowance was made for time needed to operate the trailer hand brake.

Evidence of the robustness of the gear was provided by its deliberate abuse. A Scammell tractor was backed much faster than normally and disengaged in a similar manner. In both cases, the mechanism functioned smoothly.