The Battery-electric for Milk Delivery

Page 32

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Extracts from an Interesting Paper Delivered by the Chief Engineer of the Electric Vehicle Department of the Brush Electrical Engineering

Co., Ltd.

'THE outstanding advantages of the 1 battery-electric vehicle for such urban work as the delivery of milk were dealt with by Mr. 11. W. Heyman chief engineer of the battery-electricvehicle department of the Brush Electrical Engineering Co., Ltd., in a talk which he recently gave before the southern section of the Co-operative Dairy Managers Association.

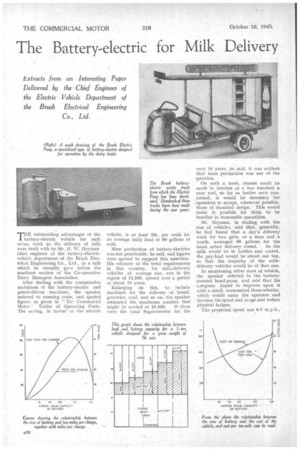

After dealing with the comparative usefulness of the battery-electric and petrol-driven machines, the speaker referred to running costs, and quoted figure as given in " Th-i Commercial Motor ' Tables of Operating Costs. The saving, in favour of the electric

vehicle, is at least 23s per week for an average daily load of 90 gallons of milk.

Mass production of battery-electrics was not practicable, he said, and figures were quoted to support this assertion. His estimate of the total requirements in this country, for milk-delivery vehicles of average size, was in the region of 12,500, spread over a period of about 10 years,

Enlarging on this, to include machines for the delivery of bread, groceries, coal', and so on, the speaker estimated the maximum number that might be needed at 25,000. If these were the total requirements for the next 10 years, he said, it was evident that mass production was out ofthe question.

On such a basis, chassis could be made in batches of a few hundred a year and, so far as bodies were concerned, it would be necessary for operators to accept, whenever possible, those of standard design. This would make it possible for them to be handled in reasonable quantities.

Mr. Heyman, in dealing. with the size of vehicles, said that, generally, he had found that a day's delivery work for two girls, or a man and a youth, averaged 90 gallons for the

usual urban delivery round. As the milk would be in bottles and crated, the pay-load would be about one ton, so that the majority of the milkdelivery vehicles would be of that size.

In mentioning other sizes of vehicle, the speaker referred to the batteryassisted hand-pram, and said that his company hoped to improve upon it with a small, economical three-wheeler, which would carry the operator and increase his.speed and range and reduce physical fatigue.

The projected speed was 6-7 mph..

as against the 21 m.p.h. of the pram, and, the 16-18 m.p.h. of the bigger vehicles. The brush Electric Pony, as it has been named, is designed to carry 75 gallons of milk, and ttill cover a daily stop-start. mileage of about 10. It is a development of the Brush indus

d trial truck, of which a large number has been supplied during the past six years.

For bulk deliveries, with daily mileages up to 40, there was a 2-3 ton flat-deck lorry that would be available. Special attention was being given to body design and construction to meet the specific requirements of the dairy trade. Apart from providing prqtection for the goods, the question of cab design was important, because of the frequency with which the driver and his assistant had to get in and out.

Dealing with chassis details, the speaker said that electric-vehicle motors, generally, may be said to be reliable. His own statistics offered proof that the average life of such a motor was 20 years before any major repairs became necessary.

Failures might be caused by sudden overloads promoting overheating of the windings.. War-time research had enabled, at least one electric-motor manufa.cturer practically to eliminate solder-throwing troubles by introducing copper brazing in place of the usual sOft soldering.

To render the insulation more resistant to heat, it is now quite a common practice to use glass cloth and other inorganic materials for insulation purposes. The use of two motors was undesirable, he said, as not only was efficiency reduced, but larger batteries were required.

Referring to the controller, the speaker said that the greatest proportion of maintenance work was, perhaps, expended on this unit. To increase the life of the drum segments or contactor tips, hard-metal alloys can now be used, being so designed as to reduce burning.

Methods of Control

On the subject of control, Mr. Heyman said that the method employed was the greatest single factor affecting efficiency. The most popular were the resistance method. and the parallel. seriessystem. With resistance control, energy was being absorbed in the resistance at low speeds, and the whole of the battery was being used. This was a wasteful procedure, particularly

latre many stops and starts are involved.

Parallel-series control, on the other hand, is so arranged that when the vehicle isrunning at half speed, only half the battery voltage is used. With this system, a definite half-speed position is provided, So that the driver is encouraged to use less current when speed is not really neccessary.

The average saving in battery size through the adoption of the parallelseries arrangerrient nia3r be said to be about 20 per cent. Additionally, the more frequent use of low speeds saves' the brake facings and, in a general way. reducea mechanical impacts when stopping.

For maximum efficiency combined with minimum weight, said the speaker, the motor should run at the maximum possible speed. His company, he said, employs a special double-reduction axle ; a 15 to 1 ratio was better than one of 6 to 1, he added.

Touching on the use of light alloys in chassis construction, it was found, said --Mr. Heyman, that the possible overall saving was toci small to permit of the fitting of a smaller battery for the same pay-load and range. On the other hand, it would be possible, through the use of such materials, to increase the pay-load by as much as 15 per cent.