Pagefield.

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

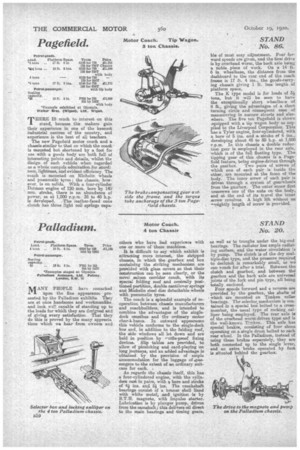

Motor Coach. Tip Wagon.

3 ton Chassis.

STAND No. 86:

THERE IS much to interest on this stand, because the makers gain their experience in one of the keenest industrial centres of the country, and experience is the best of all teachers.

The new Pagefield motor coach and a chassis similar to that on which the coach is mounted but shortened by a foot f ea use with a goods body are both full of interesting points and details, whilst the design of each vehicle when regarded as a whole compels admiration for stordi ness, lightness, and evident. efficiency. The coach is mounted on Michelin wheels and pneumatic tgres ; the chassis, however, is on solids. With a four-cylinder Daman engine of 120 mm. bore by 140 ram, stroke, there is an abundance of power, as at 1,000 r.p.rn. 38 to 40 h.p. is developed. The leather-faced cone .clutch has three light coil springs cape hie of most easy adjustment. Four forward speeds are given' and the final drive is by overhead worm, the back axle being a noble piece of work. On a 14 ft. 6 in wheelbase the distance from the dashboard to the rear end of the coach frame is 17 ft. 4 ins., the goods-carrying chassis giving 1 ft. less length of platform space. The K type model is for loads of 31 tons, but it will be seen to have the exceptionally short wbeelba:e of 8 ft., giving the advantages of a short turning circle and consequent ease of manceuvring in narrow streets and elsewhere. The five ton Pagefield is shown equipped with a tip wagon body as supplied to the Liverpool Corporation. This has a Tyler engine, four-cylindered, with a bore of 5 ins, and a. stroke of 6 ins., developing about 45 to 50 h.p. at 1,000 r.p.m. In this chassis a double reduction gear is employed in the rear axle, which is of the full floating type. The tipping gear of this chassis is a, Pagefield feature, being engine-driven through the gearbox. Two pairs of screws of which one of each pair is inside the other, are mounted at the front of the body. The inner screw of each, pair is driven through a system of gearwheels from the gearbox. The outer screw first unscrews one of the nuts on the body, and at the end of its taavel the inner screw revolves. A high lift without an ..tightly length of screw is provided.