M a ur o Zz by Bill Godwin

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Norwegian Railways: intrain with demounts

RAILWAY administrations on the Continent generally use road transport in an ancillary role to serve areas without rail links and to provide pick-up facilities at railheads. However, in some countries the politics which nurture the conflicting interests of road and rail have made this a relationship in which hauliers outside the system regard rail facilities with more than a touch of suspicion. Consequently there is only a limited amount of cooperation.

An exception to this situation is practised in Norway where the State railways — NSB — are not only the operators of the largest single road fleet in the country but are partners in a national transport pattern which, for geographical reasons, is heavily dependent on intermodal equipment, i.e. demountable bodies and containers.

They are predominantly geographical or rather topographical reasons because the country with its staggering 54,000km of coastline in an endto-end distance of just 1,700km has a rail network of only just over 4,200km. The population of around four million is widely dispersed over an area larger than that occupied by West Germany.

While the railways are, understandably, only in third place in the handling of domestic freight tonnage, coastal shipping is second and road transport has a clear lead. Because of the physical limitations of the country's rail system, "Combi transport" or the combination of two or more different modes of transport in carrying freight over a given route has been practised for many years.

Coastal shipping, particularly on the so-called joint "Nord Poolen" (North Pole) route, originally used vessels with container cells based on ISO dimensions so that difficulties arose in the handling of the standard 7.15m demount units which had already been adopted by the railways and road hauliers.

New vessels introduced during the last few years have been adapted to cater for a wider range of sizes. A typical transfer point, to and from coastal shipping is at Bodo, north of the Arctic Circle. This is the most northerly point reached by direct rail services from Oslo, 1,200km • to the south, although Narvik, the important iron ore port even further north, is linked by rail with neighbouring Sweden. The Nord Poolen operators, which also serve Bodo on the seven day run from Oslo to Hammerfest and Kirkenes, have introduced their own variant of 20ft container, based on ISO practice but incorporating landing legs and a guide 'tunnel' compatible with the most widely used lorry-based demount systems.

Many road hauliers in Norway use the Lagab system, superficially similar to the German 7.15m long demount bodies but differing in certain critical dimensions particularly in leg spacing.

Then there is the so-called Norwegian standard swap body, again 7.15m long but providing yet another variant in leg location. That this variety of equipment standards is not conducive to efficient utilisation is well recognised by all parties concerned and efforts are being made to find a solution which does not give a monopoly to a single supplier of bodies and vehicle equipment.

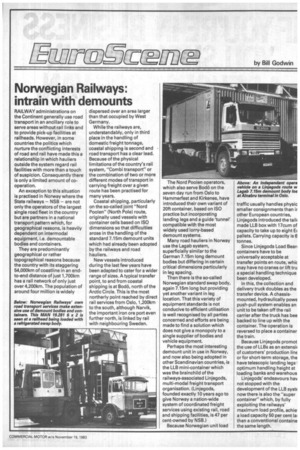

Perhaps the most interesting demount unit in use in Norway, and now also being adopted in other Scandinavian countries, is the LLB mini-container which was the brainchild of the railways-associated Linjegods, multi-modal freight transport organisation. (Linjegods, founded exactly 10 years ago to give Norway a nation-wide system of coordinated freight services using existing rail, road and shipping facilities, is 47 per cent-owned by NSB.) Because Norwegian unit load traffic usually handles physic smaller consignments than ir other European countries, Linjegods introduced the tail4 made LLB box with 17cum of capacity to take up to eight EL pallets. Carrying capacity is 6 tonnes.

Since Linjegods Load Bean containers have to be universally acceptable at transfer points en route, whic may have no cranes or lift tru a special handling technique been developed.

In this, the collection and delivery truck doubles as the transfer device. A chassismounted, hydraulically powE push-pull system enables an unit to be taken off the rail carrier after the truck has bee backed to line up with the container. The operation is reversed to place a container the train.

Because Linjegods promot the use of LLBs as an extensis of customers' production linE or for short-term storage, the have telescopic landing legs' optimum handling height at loading banks and warehous Linjegods' endeavours hay not stopped with the development of the LLB systE now there is also the "super container" which, by fully exploiting the railways' maximum load profile, achie. a load capacity 50 per cent lai than a conventional containe the same length.