TECHNICAL IMPRESSIONS PARIS SHOW

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

A FTER a close study of the exhibits at Olympia It was interesting in the same week to visit the commercial-vehicle show at Paris. This actually opened last Thursday while the London one was still attracting great attention.

' Frankly, there can be no comparison between the two shows, quite apart from the question of size. Interesting the Paris affair certainly is, but it does not reflect nearly the same degree of progress in vehicle design—either in chassis or coachwork.

We are told that French makers are so busy in the production and sale of vehicles that while such a good market exists for almost any type of machine they are loth greatly to alter their programmes. There are, of course, exceptions,.eand amongst these are to be found several new and particularly Interesting chassis, including one built with a Diesel engine as its base.

Diesels at the Salon.

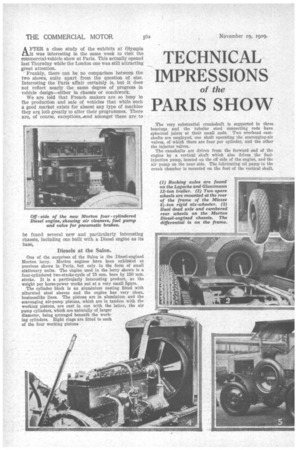

One of the •surprises of the Salon is the Diesel-engined Morton lorry. Morton engines have been exhibited at previous shows in Paris. hut only in the form of small stationary units. The engine used in the lorry shown is a four-cylindered two-stroke-cycle of 75 mm. bore by 150 ram. stroke. It is a particularly interesting product, as the weight per horse-power works out at a very small figure.

The cylinder block is an aluminium casting fitted with niturated steel sleeves and the engine has very clean, businesslike lines. The pistons are in aluminium and the scavenging air-pump pistons, which are in tandem with the working pistons, are cast in one with the latter, the air pump cylinders, which are naturally of larger diameter, being arranged beneath the working cylinders. Eight rings are fitted to each of the four working pistons

The very substantial crankshaft is supported in three bearings and the tubular steel connecting rods have spherical joints at their small ends. Two overhead camshafts are employed, one shaft operating the scavenging-air valves, of which there are four per cylinder, and the other the injector valves.

The camshafts are driven from the forward end of the engine by a vertical shaft which also drives the fuelinjection pump, located on the off side of the engine, and the air pump on the near side. The lubricating oil pump in the crank chamber is mounted on the foot of the vertical shaft. Special interest attaches to the system of fuel supply and injection. This comprises four small reciprocating pumps, a form of hydraulic accumulator and a rather curious injector. The fuel pumps are driven by eecentrics and are fitted with ball valves, whilst the accumulator consists of a cylindrical chamber in which the fuel is temporarily stored under pressure while on its way to the engine, the pressure being maintained by a spring-loaded plunger. Powerful coil springs keep the pressure between 4 kilos. and 5 kilos. per square c.m. An escape valve is provided by means of which surplus oil can return to the tank. Turning to the injector, fuel entering thi& inated

the cylinder by means of it mechanically operated valv2 through a venturi type of opening. At the Moment that the fuel valve opens a second valve admits compressed air, which tmingles with the fuel and assists in its diffusion.

The rockers for fuel and air-injection valves'arelisuperimposed and operated by the same cam. The main air supplied by the scavenging pumps enters through the four valves in the cylinder head and escapes through exhaust ports at the bottom of the stroke.

Water pump and dynamo are mounted in tandem on the near side of the engine and are driven by the same belt as the fan. The dynamo is employed only for lighting as the Hertzmark compressed air system is used for starting the engine. It may be mentioned that the-fuel pump can be hand operated before starting, in order to get up thd necessary pressure in the hydraulic accumulator. On the bench the Morton engine is said to have given 60 b.h.p. at 3,000 r.p.m. The normal engine speed, however. is 2,400 r.p.m., at which 45 b.h.p. is obtained.

A remarkable degree of flexibility is claimed for this interesting product, which is made by Moteurs Morton, 108 bis, Rue Carnot, Suresnes, Seine.

Another very interesting Diesel exhibit is that of the Compagnie Lilloise de Moteurs, a branch• of the Peugeot concern, which again shows the Junkers engines for which it has the French manufacturing rights. No particular change is made this year in the design, but two of the small single-cylindered motors are shown embodied in vehicles. The Junkers is a two-stroke-cycle type with opposed pistons arranged somewhat after the style of certain marine engines, that is to. say with twin connecting rods for the upper pistons, having a tractive effort on the cranks. The pumps for the scavenging air are located above the working ;Cylindet1 and the pump pistons are mounted on top of the working pistons.

Two types only are produced ; the single-cylindered engine, which has a bore of 60 mm. and a total stroke of 210 mm. counting the movement of the two pistons, and a twincylindered model with a bore of 80 mm. and a total stroke of 300 mm., giving a working cylinder capacity of 3 litres.

The engines develop their power at remarkably low speeds as the single gives 8 h.p. at 1,000 r.p.m. or 10 h.p. at 1,200 r.p.m., whilst the twin develops 40 h.p. at 1,000 r.p.m. and 45 h.p. at 1,200 r.p.m. The weight of the small engine, with flywheel, is 210 kilns., and that of the twin 460 kilos.

Fuel injection is effected by means of a reciprocating pump, the action of which is under the direct control of a centrifugal governor. The Compagnie Lilloise does not make complete vehicles.

LM Diesels have, however, been already adopted by several French firms, including Soniva, and, naturally, the industrial-vehicle section of the Peugeot Co. These engines are equipped with electric starters of a normal type. At the end of each working stroke the scavenging air supplied by the pump enters the working cylinder tangentially through ports at the top, blows the burnt gases out through the lower ports and continues to fill the cylinder after the closing, of tile exhaust ports. The cylinder is thus filled with clean air in readiness for the next compression stroke.

These engines are made by the Compagnie Lilloise de Moteurs, 71, Rue Marius Aufan, Levalloise, Seine, and in its Lille factory.

Other Diesel engines to be seen at the Paris Salon include the big Mercedes-Benz and the Saurer. The Mercedes-Bens unit is shown in the concern's 10-ton six-wheeled chassis.

The Saurer Diesel four-cylindered four-stroke unit shows no change since it was exhibited last year, and this engine has been fully dealt with in these columns. The engine operates on the true Diesel system, with solid injection. Pure air is taken in by the pistons on their induction stroke. Separate fuel pumps supply oil to the injector of each cylinder. A six-cylindered type is on view.

Two important innovations in the Diesel-engine field are power units made in the Renault factory. One is a fourcylinderecl engine mounted in a chassis and the other is a six-cylindered type. They have not yet been tested but are shown to indicate to the public that this maker is alive to Diesel possibilities. Both work on the four-stroke cycle, have solid injection by Bosch pump, all valves are overhead and are operated from, a single camshaft. The design of these motors is very clean.

826

Engines and Auxiliaries.

In all the Unic chassis the fan is mounted on the dynamo spindle and is belt-driven. The dynamo is carried in an aluminium cradle which is spigoted into a split housing cast with the timing-ease cover. Adjustment is provided by a large setscrew which allows the cradle to rise or fall.

Detachable-headed side-valve engines are the most popular, Latil having fallen into line in this respect recently, but the 6-ton A.S. still has one-piece cylinders and heads. Some of the smaller engines have overhead valves, as the units are also used for private motorcars. Three-point suspension is the most popular system.

An interesting new unit is the Laffly six-cylindered model with dual ignition by coil. One plug is used in each side of each cylinder. The vertical inlet pipe passes through the exhaust manifold ; a Vokes air-cleaner is installed and the governor is an American Handy operated by suction.

The engine of the new Ballet 30-seater has six cylinders, two detachable heads, three-point suspension, a combined starter and dynamo and auxiliaries driven by a cross-shaft.

Small dynaihos--to British eyes—are widely employed, many of them being driven by small belts. A common design is to mount the fan on the extended armature of the dynamo. The A.S. three-tonner is a typical example. The engine of the straight-eight Miesse, which develops 100 b.h.p., has two carburetters, two exhaust systems and double fuel tanks.

Dual ignition is found on Liberty engines and the A.S. six-tonner. The magneto of the latter can be slid along to replace the dynamo if that unit should fail.

Gearboxes.

Unit construction of the engine and gearbox is commonly adopted in new designs, but the Bullet six-cylinder chassis for 30-seater bodies is an exception. Three selector rods from the gate to the box is general practice, just the reverse of British procedure. The. Lilloise 1-ton Diesel-engined chassis has the gearbox mounted on the rear axle. The new Laffly " six " has an auxiliary two-speed gearbox with helical-toothed gears and dog-dutch engagement, behind the main box. A heavy Somua chassis has both main and subsidiary boxes housed in a common easing.

Transmission.

Chains are found on certain heavy-duty chassis of French origin, but the vast majority has cardan-shaft drive. Torque tubes or torque members are more widely used than in this country. Offset transmission is not usually adopted. On the Pierce-Arrow the rear axle is located by radius rods and a torque arm is employed. The A.S. three-tanner has separate components to counter torque and drive stresses, but the six-tonner has Hotchkiss drive.

A central bearing in the torque tube is used in one De Dion design, whilst another has a one-piece tube anchored to a pendant link at its forward end. Transmission brakes naturally affect the shaft layout on many makes.

Axles and Final Drives.

Unics seem fond of double-reduction axles, there being either spur-and-bevel or bevel-and-spur tyres on all models of this make.

Bernard, Rochet-Schneider and others also employ double reductions to a remarkable extent. A dual-type axle with vertical banjo and external driving shafts to internal gears in the hubs is used on the Soma bus chassis. The Morton Diesel-engined machine has a dual dead axle carrying cambered wheels which are driven by universally jointed shafts from a sprung differential. The Mathis light six-wheeler has one dead and one live axle in the bogie, the former having a wider track than the latter.

Underslung worms are used in the Miesse bogie: the springs are not arranged to pivot on the axles. La Licorne and Berliet use, in certain instances, truss rods below the axles.

Suspension.

The Cottin and Desgouttes ambulance has a front cross spring and the stub axles mounted on vertical plungers carried in tubular housings fixed to extensions of the frame front cross-member. The rear• wheels are carried on four laminated cross springs, the drive being from a sprung dif ferential via cardan shafts. Quarter-elliptic springs are secured to the ends of the frame on the Peugeot 201 chassis for .8-cwt. loads. These springs run forward and splay out to the rear axle, to which they are shackled. The axle itself has a torque tube and underneath-worm drive. Reverse-cambered springs are common, the Berliet 30seater being a good example. The Miesse six-wheeler has underslung front springs and rebound dampers. A Delahaye 16-seater employs double-acting friction-type dampers. A.S. and Liberty models have oil reservoirs in the spring shackles.

Brakes.

The transmission-brake drum of the largest Cottin and Desgoutte,s passenger chassis is mounted at the rear end of the forward half of the propeller shaft immediately in front of the double pressed-steel cross-member supporting the torque tube spherical housing. There are actually three brakes, a foot acting through the Dewandre, on all four wheels, and a hand brake only on rear wheels, in addition to the transmission brake. This is a precaution considered

necessary, for work in mountainous country. It is one

which might well be considered for some British vehicles. The Unic mechanical booster for the foot brake is used on all models of this make. It affords a rapid take up and increasing leverage. Rubber bushes in small steel brackets prevent whip on the brake rods of the Unic. The cables of the Bernard chassis are protected by rubber and canvas tubes at points where they might be frayed against adjacent parts. A conductor's emergency brake lever is provided on the rear platform of the Somua overtype bus. Two hand brakes and a foot-operated brake with Westinghouse servo are provided on this make of bus chassis. One hand brake acts on a transmission drum behind the gearbox. Oil operation of the brakes is used on the Dewald chaindriven lorry. Compressed-air braking is installed on the Morton chassis, whilst the other machines usually employ vacuum-servo devices. Cables are more widely used than in Great Britain. The new Lath "six" has three brakes, two being band operated and one—on all wheels—by foot. The Marelli

servo is used. Compensation is very popular, and, in general, this leads to rather untidy and complicated designs. Three Bosch Dewandre servos are used on the MercedesBens Diesel-engined six-wheelers, one large type for the front wheels and those of the bogie forward axle whilst two are provided for the brakes of the bogie rear axle. The connection to the cylinders runs to a junction and thence to the rear brakes.

Frame Construction.

Most of the frame arches over the back axles are reinforced by short lengths of channel steel either inside or outside the main-frame members. In the Cottin and Desgouttes there is a liner and an outer plate above and below, the liner being cut away in the web for lightness.

Built-in front bumpers are much in favour, whilst triple bars, spring-mounted, are usual on large chassis intended for passenger duty.

Two spare wheels are supplied with certain Mathis and Miesse machines. On the six-wheeler Miesse they are carried vertically at the extreme rear of the chassis.

-R-sdiator guards' are installed on heavy models of most makes of American origin, as are towing hooks.

Trailers.

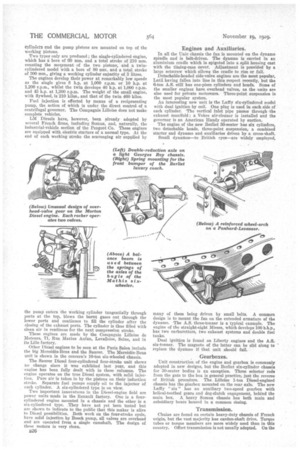

A notable exhibit is the Lagache and Glaszmann sixwheeled trailer with the four rear wheels set in line in pairs on short axles, the single springs of which are permitted a rocking motion, rubber cushions limiting the movement. The trailer forms part of a Chenard-Walcker tractor and trailer outfit, and, in some respects, is not unlike a wellknown British make.

A Coder trailer is shown with a ball-bearing turntable.

Publicity.

Paquette stages a neat van with a roller-blind type of announcing device showing through cut-away panels at each side.

One of the most striking publicity vehicles is the ChenardWaleker Dunlop van with a body by Des Garages de France. The word "Dunlop" is in polished aluminium raised lettering on the sides. At the back is a figure, the mouth of which forms the stop light, whilst the illuminated arms are direction signals.

Road Tractors.

A new development is the six-wheeled 21)-ton tractor of Chenard-Walcker construction. The rocking beam is centrally pivoted and the drive to each wheel is by gears. The

axles are mounted at the ends of laminated springs, and volute damper springs carried on frame brackets limit the rocking of the beams. The design resenibles that of the Scamp-mil rigid six-wheeler, except that the ends of the rocker beams are joined by the two axles. A novelty is

Dewandre servo braking for the trailer. Two examples of the Ara chain-track tractor are on view, the larger equipped with a gas-producer standing at a height of about l ft. and giving the machine a most unwieldy appearance.

A rather interesting form of rubber-pad non-slip device for bolting in sections over twin-tyred wheels is being used by Chenard and Walcker. The pads are carried in staggered pairs by castings, the latter being secured by right and left-hand threaded bolts.

Bodywork.

The Fauraux and Chaussende ambulance body on ia Cottin and Desgouttes chassis has much the appearance of a private car. There are doors at each side, double doors at the back, one stretcher and a single seat facing forward.

Some coaches have small let-down tables in seat backs, a picture of some scenery being mounted under the glass cover.

In Fauraux and Chaussende coaches armrests on. the gangway side are permitted a 2-in, movement, otherwise the gangway would be so narrow as to forbid the passage of portly Persons. Even with this precaution, the space is very restricted. Other bodies of the same make have hinged seats with -hinged backs for gangways.

Rena= has a handsome boxvan with metal panels up to the waistline, and canvas. over wood above this and in one with, the roof. The back is divided horizontally and the parts are hinged at top and bottom respectively.

Another Renaux service bus has standing accommodation in front, two hinged seats and the driver's seat barred off by a tubular pillar and horizontal members, one member being hinged to permit access. There is a luggage ladder at the back and a window is protected by a neat wire grill.

One van with roof accommodation has a long binged step at each side at the waistline level.

The Unic milk float is well arranged for loading, affording access from the front beside the driver's seat, at the sides and at the back. It provides extra room by means of a removable second tier.

One of the most striking bodies on Unic chassis is a well-arranged coffee stall with unusually complete and wellarranged fittings, such as a large sink and mimeriMs cupboards. The body is by Paquette, and is lined in thick paper,' made to imitate beaten metal, and celltilbse'painted. The wind-back sunshine roof on the Fauraux and Chanssende body of the Bernard Six is operated by a handle in the roof of the driver's compartment There is a neatly arranged lavatory at the back and a rear door giving access to the luggage compartment beside the lavatory. We noted with interest that the water-filler cap for the basin-supply tank is situated under the last seat on the left side.

A double set of twin folding doors is used for the rear entrances of the Somua bus : each folding section is only C ins. wide. This gives entrance and exit simultaneously.

. True Weymann construction was to be found on a few vehicles, a notable example being by Paquette on a Somua, this, incidentally, being the coach with a Rex gas-producer, The Somua bus for Poland has perfectly flat metal panels with a kind of buffer strip along each side, apparently to avoid scratching the main panels in case of a minor collision.

At the rear of the Peugeot taxicab is a permanent extension forming a wide luggage carrier, and the corner buffer bars are mounted on this extension. The arrangement is practical but presents a somewhat curious appearance when not loaded. It would constitute a heaven-sent opportunity for the small boy hanger on.

Incidentally the meter on this cab is the smallest gild neatest which we have ever seen. It measures approximately 7 ins. by 6 ins. by 3 ins. and. is built unden the A. Brun licence by Goury, Martin, Calliat and Co., 3 his Rue de l'Essai, Paris.

On the coach by Meulemeester Freres on a Bernard chassis the sliding roof is operated by a pinion with skew teeth meshing with a larger gear which is itself meshed with a second gear of the same size. Each of these large gears carries a chain sprocket which drives the roller chain for its side of the roof. On the roof at each side is a long rod with short arms pressing down on to the roof material, and release cords pass through to the interior of the vehicle.

There is -a very handsome Renault coach for the services of the P.L.M., the armchairs being upholstered in real leather and having roll headrests. Each seat has a combined table and map carrier in the back. There are woven leather hand• grips on the front bulkhead and seats, lockers over the wheelarthes, parcel nets at sides and a domed roof.

The Solcar on a Laffly six-wheeler is almost like a diningsaloon with its movable armchairs and little round tables. They are actually attached to special places on the floor by means of a single coil tension spring for each.

A four-wheeled Mercedes-Benz is shown with all-steel bodywork of the riveted pattern. This vehicle has a single wide entrance with double folding doors opening on to a central vestibule; a second door is provided for the driver's seat and as an emergency exit for the passengers.

The driver's seat is enclosed and a single seat for a passenger is positioned at the side of his cabin. The kicking plates and lower panels in the vestibule, etc., are in beaten copper.

Tipping Gears.

On the Bernard tipper the gear used is a twin-ram hydraulic pattern. The rams act on a bar which is secured by links to the frame of the body ; this method enables the gear to be secured rigidly to the main frame.

The tipping gear on the Somua is a twinram hydraulic with pivoting cylinders; it is known as the Pillot. A cross-bar for the rams is, in. this case, carried in brackets bolted to the body frame.

A large single hydraulic ram of the pivoting pattern is used on the Dewald tipper. The hand-operated Pinot tipping gear has curved racks operated through a reducing gear.

A type of curved-rack gear closely resembling the Pilot is staged by Fernand Geneve, who also had two types of the Woods Horizontal Hydraulic, one for end tipping only and the other for three-way operation.

In each case a ram with rollers at its end forces up a cam-shaped casting. In the three-way gear the cam ends in a cup holding a large steel ball which runs along a casting constituting a curved track and bolted to the body.

In the foregoing paragraphs we have made no reference to mechanical details on chassis which are sold in Great Britain. These, of course, have, from time to time, been described in full, and many of them were on view last week at Olympia. In our next issue we shall deal with further aspects of the Paris Show.