Power-propelled Plant for ROAD-CONSTRUCTION WORK

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

TIIE speed with which mechanical methods nowadays gain ascendancy over hand labour is, perhaps, nowhere better exemplified than in the case of road construction. Only a short time ago—or so it seems—the pick and the shovel were almost the sole mechanical equipment of the road maker. He used horses and carts for transport and turned to power for assistance only when a roller was needed to finish off his.; work. Now there is hardly an operation in road niaking and road mending for which there is not suitable mechanical equipment Furthermore, an increasingly rapid growth of this tendency to use power-driven appliances would, no doubt, prevail but for the -..fact that., so far as municipal authorities, at least, are concerned, there is a certain amount of constraint towards the use of manual labour wherever reasonably possible so as to provide a certain amount of work for the unemployed.

This is not a suitable occasion for labouring a point which has, in this• connection, often occurred to us, but it may be as well just to mention that, in our view, the more widespread use of mechanical equipment, accompanied by such extensions of operationsas would ,enabie employment to be found for those without work, would be a more logical and practicable Way of tackling that 'particular difficulty.

To show how mechanical equipment facilitates the operations of road breaking and making, a short rkurne of the methods and appliances that are employed' will be of interest, and, as an examPle, we propose to take the case.of a concrete ,road, with Tarmac covering, which is being broken up and renewed.

Road Surface. The Task of Removing the

The first Operation is the removal of the Tarmac covering or carpet. The thickness of this surface varies, but in the case of most roads which have been laid sufficiently long to necessitate the procedure that we have in mind, about 2 ins. is what may be generally expected. This is broken up, as 'a rule, by hand picks, and the first use of mechanical appliances is that of a motor lorry to take this material away to some place where it can he remelted, for it has the advantage that .it may he' used over and over again. In the case of wood blocks, the same procedure is adopted, except that, of course, the blocks are :taken away and finally burnt.

-There is a peculiar feature about these road coverings which is worthy of note. The material, as a rule, comes clean away from the surface of the concrete upon which it is laid, unless it has been laid down upon a wet surface. Wood blocks, an the other hand, ceme. clean away:tram the under surface—inCleed, they are apt to come away prematurely if that -surface 'was

I318 wet at the time at which the blocks were put down. Having taken off the carpet, the next procedure is the breaking down of the concrete which forms the body of the road.

For this •purpose pneumatically driven concrete breakers are used. To drive them compressed air is necessary, and this is usually provided by means of portable compressors which are powered by petrol engines. The alternative—electrically driven compressors —is available for cases in which it is possible to take current from the mains. The petrol-driven type is at present, however, the more popular.

Type of Compressor Used.

These eompressers, as a rule, vary in output between 100 and 400 cubic. ft. per minute, these figures indicating the volume of air before it enters the compressor. More correctly, it should be set down as 100 to 400 cubic ft. of free air. The compression pressure is apr proximately 80 lb. per square end 100 cubic ft. per minute will• serve about four pneumatic 'picks. An esiential feature of a good compressor is its • capacity to run for long periods without attentidn, .and this involves, amongst other things, ample radiator capacity, sothat -there is 4o tendency'

manufacture useful equipment of this class.

Some constructors favour the use of portable air ,compressors which. are capable of being moved under their own power. As a rule, an internal-combustion-engined tractor is , the main element of these units, and the tractor engine serves as the power unit of the compressor. . .

Pneumatic Tools for Road Destruction.

The pneumatic tools that are used in this work are four'in number. There is, the 'pneumatic pick,_ the concrete breaker "(which is 'a More powerful tool of. a tVpe: similar to' the .pick), end. a " spader " (which is -usedmainly for clearing the subsoil, when, for purposes of 'construeting a new road, it is necessary to go a little deeper than was pteviously thoUght to be needful). The fourth tool, 'a tamper, is Used, as its name implies, for tamping down the. material with ,which any trench or road has been filled. • .

As the old road material is broken up it has to be cleared 'away, 'ind; far 'this purPose, -motor lorries 'are; of 'course, invaluable. In the majority at eases they are. loaded by hand; but where.the work' which IS going forvirard is on a more-than-usually ambitious scale, and

in instances in which there is a large quantity of Material to be moved, power shovels, as made by the Chaseside Engineering Co., or similar to that shown at Olympia in connection with the Rushton tractor, and produced by Muir Hill (Engineers), Ltd., of Manchester, arc used. Equipment of this kind will shovel 20-30 tons per hour.

If the material of the road be concrete, it is sometimes permissible to break it up and use it again, in which case one of two methods is followed. Either the old concrete is taken back to the contractor's yard and there broken up, or—and this, of course, is more economical with regard to time and money—a battery of crushers is located in a side street.

Having removed the old concrete, the subsoil is next dug up, so far as necessary, and then construction starts.

Sometimes, in eases in which the

subsoil is clay, a layer. of 3 ins. or 4 ins. of cinders or similar material comes first, then the concrete, which, in connection with a London street that we were recently examining, waslaid on to a thickness of 8 ins., and, after that, the carpeting, which, again, in this particular instance, was 4 ins. thick, and consisted of Tarmac, 3 ins, of it being rough and the top inch a fine coating.

For the mixing of the concrete mixers of the type illustrated are commonly employed. They are capable of mixing and delivering or cubic yd. per minute. In the course of a working day one of these machines will mix 200 cubic yds. of concrete, and that, in. a 27-ft. road, is equivalent, roughly, to 10 yds. of road per day per machine. In that calculation due allowance has been made for the fact that the concrete, after being laid, shrinks to the extent of about 10 per cent.

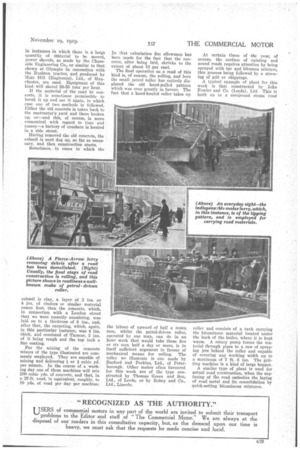

, The final operation on a road of this kind is, of course, the rolling, and here the small petrol roller has entirely displaced the old hand-pulled pattern which was once greatly in favour. The fact that a hand-hauled roller takes up

the labour of upward of half a dozen men, whilst the petrol-driven roller, operated by one man, can do in an hour work that would take those five or six men half a day or more, is in itself sufficient argument in favour of mechanical means for rolling. The roller we illustrate is one made by Barford and Perkins, Ltd., of Peterborough. Other makes often favoured for this work are of the type constructed by Thomas Green and Son, Ltd., of Leeds, or by Robey and Co., Ltd., Lincoln.

At certain times of the year, of course, the surface of existing and sound roads requires attention by being sprayed with tar and bitumen mixture, this process being followed by a strewing of grit or chippings.

A typical example of plant for this work is that constructed by John Fowler and Co. (Leeds), Ltd. This is built on to a compound steam road roller and consists of a tank carrying the bituminous material located under the hack of the boiler, where it is kept warm. A rotary pump forces the material through pipes to a row of spraying jets behind the roller and capable of covering any working width up to a maximum of 7 ft. 6 ins. The gritting machine is a kind of large hopper.

A similar type of plant is used for actual road construction when the supfacing of the road embodies the laying of road metal and its consolidation by quick-setting bituminous mixtures.