from Drivers &Mechanics

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs. ...

Light Up Your Lamps At 5.5 on Thursday ; 5.4 on Friday ; 5.3 on Saturday ; 5.1 On Monday ; 5.0 on Tuesday ;. 4.59 on Wednesday.

Fitting a Clutch Thrust-centre.

[1562] " A.H.H. " (Landaff) writes :—" Some little while back I had to overhaul a clutch of the multiprate type. Upon close examination, I found that

the spindle of the clutch had a lot of play lengthwise, so I decided to fit a steel thrust to the flywheel, so as to take up the slack. The manner in which I effected this will be understood from the following description. I also enclose a sketch [We have had this redrawn.—En.] showing the thrust disc.

"First of all I had to recess the centre of the flywheel to a depth of 1 in., and to a diameter of 3 ins. Not having any 3-in, steel bar in stock at the time, I proceeded to make up the thrust disc as follows : I cut off a piece of round bar-steel I-in. diameter, and faced it to in. thickness, after which it was case hardened. I then procured a piece of fibre A in. thick, and cut a disc out 3 ins, in diameter, and afterwards bored a 1 in. hole in the centre. Into this disc the piece of case-hardened steel was forced. I then fitted the steel-and-fibre disc into the flywheel recess, and bolted the clutch in position."

Hints on Valve Grinding.

[1583] " W.A.V." (Hounslow) writes :—" I thought possibly a few remarks on valve grinding would be of interest to readers of the '0. and M.' pages. It is an operation which is carried out every day in most garages, but there is not always the necessary amount of care exercised in the grinding in and cleansing process, and I know of several instances in which trouble has ensued through bits of cotton waste, as well as emery, fouling the valve seats. "During the operation of grinding in the poppets, great care should be exercised to prevent the cutting compound from getting into the valve-guides and cylinders. The ports should be well plugged, as also i should the space under the valve-head. It s better that the cotton waste used for this be thoroughly soaked in oil before being packed, as this will tend to prevent bits of waste from getting loose. The oil also serves to collect most of the cutting compound which works past. "After grinding in all the valves should be well washed with paraffin, and their guides should also be well flushed. My experience is that exhaust valves require grinding in about every MOO miles, whilst inlet valves, in the ordinary way of service should not require attention until they have run 2500 miles."

Number-plate Dimensions.

[1561] " H.B.S." (Cheshire) writes :—" I have read with great interest many of the articles in your 'P. and M,' pages dealing with almost everything mechanical, and also tips which help inexperienced readers to gain a great deal of knowledge on all kinds of subjects connected with driving and repairing, which knowledge would only otherwise have been gained by a great deal of experience and trouble.

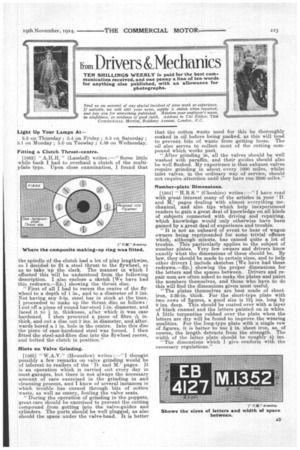

"It is not an unheard of event to hear of wagon owners being reprimanded for some trivial offence which, although minute, has caused quite a lot of trouble. This particularly applies to the subject of number plates. Very few owners and drivers know exactly what the dimensions of these should be. By law, they should be made to certain sizes, and to help other drivers I include sketches [We have had these redrawn.—En.] showing the proper dimensions for the letters and the spaces between. Drivers and repair men are often asked to make the plates and paint the numbers themselves, and those who have to do this will find the dimensions given most useful.

"The plates themselves are best made of sheetiron, 3-32-in. thick. For the short-type plate with two rows of figures, a good size is 121 ins. long by 8 ins. deep. This should be coated over with a layer of black enamel and the letters painted on in white. A. little turpentine rubbed over the plate when the letters are dry will be found to improve the wearing qualities. For the long-type plate with a single row of figures, it is better to use in. sheet iron, as, of course,. the length detracts from the strength. The width of the latter plate should be roug y 4i ins.

"The dimensions which T give conform with the necessary regulations."