When it comes to access Simon has a platform

Page 90

Page 91

Page 92

If you've noticed an error in this article please click here to report it so we can fix it.

Bill Brock visits the West Mids firm that introduced hydraulic access equipment in the Fifties and has gone on from there

SIMON ENGINEERING, based at Dudley in the West Midlands, introduced hydraulic access equipment to the United Kingdom in the early Fifties. Since then the company has developed a range of equipment which includes 52 basic models, both self-propelled and vehicle mounted, providing fully extended platform heights from five to 30m (16 to 98ft).

As the market leader in its field, the company claims to provide a platform for every standard access application.

The range includes scissor ifts, general-purpose hydraulic kitforms, telescopic platforms, ire-fighting rescue units and ;pecial-purpose platforms such is those used for aircraft refueling.

Larger units can take up to hree months in build and esting, so it may be understood hat production volumes of up to 500 units a year are more im)ressive than the number alone night imply.

While other companies have 3egun to produce equipment at he lighter end of the market, 3imon has tended to promote its 3xpertise with its larger models. lowever, it still competes, and loes good business, with its 'scissor lifts used for iniustrial maintenance and conttruction work. A range of five nachines gives working heights )f 6.1 to 16.5m (20 to 54ft). All ;elf-propelled, the smaller -nachines are battery powered Nhile the two larger units use a Mese! engine.

The smallest machine has a travelling height of only 2.3m 17.5ft) and measures only 0.75m I29.5ft) wide, making it suitable for use in confined areas.

It was not until 1961 that the company developed a hydraulic platform specifically for firefighting and rescue work. Today all major brigades in the UK are equipped with one of the Simon Snorkel units within the 15 to 30m (49 to 98ft) range. They are used in more than 60 countries.

Similar in principle to the hydraulic work platform, the firefighting appliance throws heavy jets of water and/or foam and can carry up to seven people at rescues.

Two thirds of total production is exported, but only the slewing rings are imported and many of the components are manufactured locally in the Midlands. Low production volumes make it uneconomic to produce individual components in-house so items such as hydraulic cylinders and control valves are contracted out but produced to Simon's own designs and standards. The Dudley operation consists mainly of assembly, fabrication and mounting to one of the many approved vehicle chassis.

The equipment incorporates built-in stops or safety links which prevent misuse and resultant instability, without resorting to bells, hooters or flashing lights.

The cost ratio works out roughly on a 60/40 basis with the vehicle chassis so there is always pressure on the designers to install larger machines on smaller vehicles.

Since the chassis acts as ballast the size of the vehicle imposes some limitation on the versatility in the reach of the hydraulic arms. Most equipment is mounted on its own mainframe, which incorporates integral stabilising jacks. The mast, weighing between 0.8 tons and 11 tons, itself contributes to the operational stability, but jacks are needed to provide a solid base, independent of the vehicle suspension.

On light 3.5-ton chassis the weight of the conventional integral jacking system detracts both from the size of the hydraulic lift and any spare load capacity. Simon's answer to the problem is a much lighter stabilizer leg which extends from beneath the platform to the ground. Hinged at the top the jacks can be lowered behind the wheels of the drive axle.

If the vehicle is reversed, they locate automatically with the weight of the vehicle and equipment on the extended inverted feet preventing depression or lifting of the vehicle springs.

In the under 7.5-tonne bracket the PCARA 145 was designed to be compact and safe while providing improved working height and operational flexibility. Mounted on either a Dodge 50-Series or Mercedes-Benz 605 van chassis, it has a maximum working height of 16m (52ft 6in), platform outreach of 7.4m (24ft 3in) and a safe working load of 200kg (440Ib) with stability jacks extended.

The platform can be returned from the maximum outreach position to the travel mode without power. When the boom is raised or lowered the parallelogram action of the Sim link safety linkage keeps the second boom at a constant angle and so obviates the need for stop mechanisms.

With the larger vehicles, the weight of the mainframe and jacking system allows a wider base, and in the middle ranges Simon restricts movement into unstable areas in two ways.

For its CA range (compensated articulation) the square section booms are also equipped with Simlink mechanical linkage while the TRA 180 uses a telescopic main boom with an articulated top-section. Up to about 20m (66ft) extension, the power take-off provides sufficient power with the engine running at tickover speeds, but larger models are provided with a hand throttle.

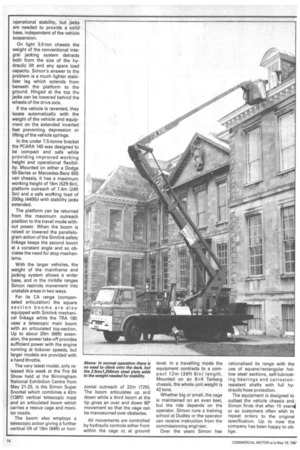

The very latest model, only released this week at the Fire 84 Show held at the Birmingham National Exhibition Centre from May 21-25, is the Simon Super Snorkel which combines a 42m (138ft) vertical telescopic mast and an articulated boom which carries a rescue cage and monitor nozzle.

The boom also employs a telescopic action giving a further vertical lift of 19m (64ft) or hori zontal outreach of 22m (72ft). The boom articulates up and down while a third boom at the tip gives an over and down 90° movement so that the cage can be manoeuvred over obstacles.

All movements are controlled by hydraulic controls either from within the cage or at ground level. In a travelling mode the equipment contracts to a compact 12m (39ft 6in) length. Mounted on an 8x4 Terberg chassis, the whole unit weight is 42 tons.

Whether big or small, the cage is maintained on an even keel, but the ride depends on the operator. Simon runs a training school at Dudley or the operator can receive instruction from the commissioning engineer.

Over the years Simon has rationalised its range with the use of square/rectangular hollow steel sections, self-lubricating bearings and corrosionresistant shafts with full hydraulic hose protection.

The equipment is designed to outlast the vehicle chassis andSimon finds that after 15 years4 or so customers often wish to repeat orders to the original specification. Up to now the company has been happy to oblige.