New 2-stroke Orbital Engine Demonstrated

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

DEM ONST R AT1ONS were held last week of the novel two-stroke petrol-engine which William R. Selwood, Ltd., and Mr. Cecil Hughes have developed. Details of the unit were given in The Commercial Motor of May 5, 1961.

For the demonstrations, the engine was mounted on a fabricated stand, coupled to a Roots supercharger which was belt driven from the output shaft of the engine. There was no load on the engine apart from that required to drive the supercharger. A suction fan and air trunking served both to take away exhaust fumes and to provide an air flow for cooling.

In effect, all that the demonstrations did, and in fact were intended to do. was to prove the principle of the design and to show that the engine did work. This was effectively accomplished and the engine was run at speeds in the region of 3,000 r.p.m. without any trouble. Throughout the speed range, vibration was virtually non-existent.

Compression ratio of the engine was 3 to I. It was said that the low figure had been selected so that there would be

no danger of over-stressing the engine, as only one set of parts had been made. As a result, thermal efficiency and power output would be low, and if performance figures had been given they would not have shown very much.

The exhaust manifold assembly for the engine is in the form of a ring which is a stationary member and completely encircles the rotating mass of the engine. Means arc incorporated to alter both the degree and the timing of the closing of the exhaust ports. This can be done either manually or automatically while the engine is running, so that the portage limitations of a conventional two-stroke engine, where exhaust closure is a function of the piston, are overcome.

Exhaust Ring Left Off The exhaust assembly was not fitted during the demonstrations, so the effect of the adjustable porting could not be assessed. Mr. Hughes said, however. that during previous tests considerable improvements had been made with the assembly fitted.

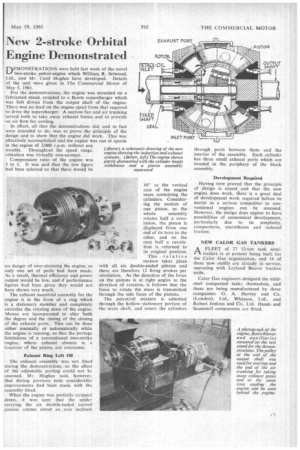

When the engine was partially stripped down, it was seen that the spider carrying the six double-ended curved pistons rotates about an axis inclined

100 to the vertical axis of the engine mass containing the cylinders. Considering the motion of one piston, as the

whole assembly rotates half a revolution, the piston is displaced from one end of its bore to the other, and on the next half a revolution is returned to its original position.

This relative motion takes place with all six double-ended pistons and there are therefore 12 firing strokes per revolution. As the direction of the force on the pistons is at right angles to the direction of rotation, it follows that the force to rotate the mass is transmitted through the side faces of the pistons.

The petrol/oil mixture is admitted through the hollow stationary portion of the main shaft, and enters the cylinders through ports between them and the interior of the assembly. Each cylinder has three small exhaust ports which are located in the periphery of the block assembly.

Development Required

Having now proved that the principle of design is sound and that the new engine does work, tfiere is a great deal of development work required before us merits as a serious competitor to conventional engines can be assessed. However, the design does appear to have possibilities of economical development. particularly due to its simplicity, compactness, smoothness and reduced friction.

NEW CALOR GAS TANKERS

AFLEET of 27 I2-ton tank semitrailers is at present being built for the Calor Gas organization, and 14 of these new outfits are already in service, operating with Leyland Beaver tractive units.

Calor Gas engineers designed the mildsteel comparted tanks themselves, and these are being manufactured by three companies: G. A. Harvey and Co. (London), Ltd., Whessoe. Ltd., and Robert Jenkins and Co., Ltd. Hands and Scammell components are fitted.