FROM TIP-WAGON TO TAR-SPRAYER.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A Steamer Convertible from a Three-way Tipper to a Steam-heated Tar-sprayer. An Appliance for the Highways Engineer.

MIIERE has just been supplied to the Perth County

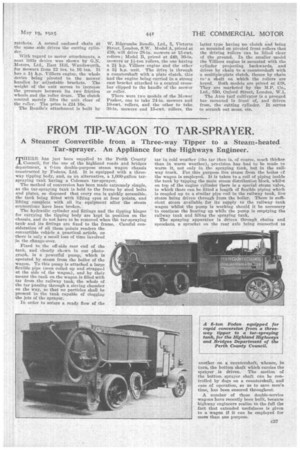

Council, for the use of the highland roads and bridges departnient, -a (1-ton double-purpose steam wagon chassis ConstruCted by Fodens, Ltd. It is equipped with a three. way tipping body, and, as an alternative, a 1,000-gallon tarspraying tank having a Coleman tar-sprayer.

The method of conversion has been made extremely simple, as the tar-spraying tank is held to the frame by steel bolts and plates, so disposed that every one is quickly accessible. the tank being fitted with lifting eyes at four points, and lifting complete with all its equipment after the steam connections have been broken,.

The hydraulic cylinder and fittings and the tipping hinges for carrying the tipping body are kept in position on the chassis, and do not have to be removed when the tar-spraying tankand its fittings are fixed to the frame. Careful consideration of all these points renders the convertible vehicle a practical article, as there is only a small loss of time involved in the change-over.

Fixed to the off-side rear end of the tank, and clearly shown in our photograph, is a powerful pump, which is operated by steam from the boiler of the wagon. To thiS pump is attached a large flexible pipe (seen coiled up and strapped at the side of the wagon), and by their means the tank on the wagon is filled with tar from the railway tank, the whole of the tar passing through a sieving chamber on the way, so that no particles shall be present in the tank capable of clogging the jets at the sprayer.

In order to secure a ready flow of the

tar in cold weather (the tar then is, of course, much thicker than in warm weather), provision has had to be made 10 warm it, not only in the spraying tank, but in the railway truCk. For this purpose live steam from the boiler cf the wagon is employed. It is taken to a coil of piping inside the tank by tapping the main steam distribution block, whilst on top of the engine cylinder there is a special steam valve, to which there can be fitted a length of flexible piping which is coupled up to a similar pipe coil in the railway tank, live steam being driven through from the boiler. There is .snfficient steam available for its supply to the railway tank wagon whilst the pump is working should it be necessary to continue the heating up while the pump is emptying the railway tank and filling the spraying tank.

The spraying apparatus is driven through_ chains and sprockets, a sprocket on the rear axle being connected to anotheron a countershaft, whence, in turn, the bottom shaft which carries the sprayer is driven. The motion of the bottom sprayer shaft can be controlled by dogs on a countershaft, and ease of operation, so as to save men's time, has been ensured throughout.

A. number of these double-service wagons have recently been built, because highway engineers realize to the full the fact that extended usefulness is given to a wagon if it can be employed for more than one purpose.