A NEW RANGE OF LIGHT CHASSIS.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

First Published Details of the Gilford 30-cwt., 2-ton and 50-cwt. Models, and Notes on a Test Run on One of Them.

MHE CONSTRUCTORS of the new

Gifford chassis, E. B. Horne and Co., 465 and 465a, Holloway Road, London, N. 7, have had many years' experience in the servicing of several types of commercial vehicle, and have actually reconditioned some 500 Garfards, with the result that they can claim to possess firstt-hand knowledge of the essential requirements of a commercial chassis.

The Garford has proved very successful in service, and, as a result of this, many points on the new Gifford bear a close resemblance to those of the Garford. Standardized components which have shown themselves to possess a long wearing life are used to a considerable extedt.

The range of models includes chassis of 30-cwt., 2-ton and 50-cwt capacity, as well as special types with a low frame level, and we were recently afforded an opportunity for a test run of some 40 miles on the 2-ton type.

Using No. 3 petrol, there was a slight amount of popping when we started away, but this ceased within a few hundred yards as we threaded our way through the traffic of Holloway Road on to the Great North Road. With a test load, including the body, of 2 tons 17 cwt. 2 lb., and with the wheels shod with giant pneumatic tyres (38 ins. by 7 ins. at the rear and 36 ins. by 6 ins, at the front), the Gifford ran almost as smoothly as a private car.

The North Road is by no means devoid of hills, some of them quite long enough and with sufficiently steep gradients to enable the running powers of the vehicle to be estimated fairly exactly, and we were certainly agreeably surprised at the manner in which the engine, which is rated at 22.5 h.p., hauled its load, which totalled 4 tons 13 cwt. 1 lb., on top gear, gave steady even pulling down to 7 m.p.h., whilst changes from second to top were easily made at 10 m.p.h.

The particular chassis we tried had a three-speed gearbox, and the only fault we found Was that there was too large a drop between top and second ; but as a four-speed box is being standardized on the 2-ton chassis, with a three-speed box as alternative equipment, this criticism no longer holds good.

We took the opportunity of making a fairly accurate test of the petrol consumption. Running until dry with a measured half-gallon and a drained float chamber, and then returning with a second half-gallon over the same route, this gave 14.6 m.p.g. going and 13.20

m.p.g. returning, the distance for the complete gallon being 13:0 miles with the aforementioned weights : this gave a gross ton-mileage of 64.8, and a tonmileage for the pay load, allowing 10 cwt. for the body, of 33.01. We found that a constant speed of between 20 and 25 m.p.h. could be maintained without any difficulty, and 32 m.p.h. was easily achieved without causing undue vibration, although the final-drive gear ratio was slightly low at 7.25 to 1, which can be changed to 6 to 1 at the option of the purchaser if the vehicle be required for running in fairly level country.

We will now describe the chassis in detail. The power unit is a four-cylinder monobloc of 31 ins, bore and 51 ins. stroke. It •develops 25 b.h.p. at 1,000 r.p.m. and 36 b.h.p. at 1,800 r.p.m. The cylinder head is removable, and the combustion chambers are machined all over. Each piston has three rings at the top and a scraper ring at the lower end, whilst two positive locking devices are provided for each gudgeon pin, one of these consisting of an alloy-steel screw and the other of a spring ring at each side of the pin.

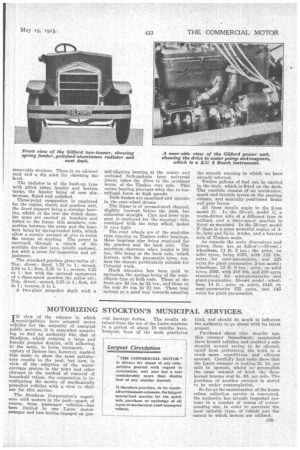

Water is circulated by a centrifugal pump, and driven in line with this, through a vernier coupling, is a ZU4 Bosch magneto. A. feature of the pump is that its two glands are most accessible and that any water which might leak through them will not run into the crankcase. The 18-in, fan consists of a centre with four riveted steel plates driven by a wide, flat belt from the forward end of the pump-drive shaft. It is mounted on an eccentric spindle for adjustment. An integral casting is employed for the inlet and exhaust manifold, thus affording a hot-spot for the Zenith carburetting device.

Three main bearings are employed for the crankshaft, and the connecting rods are of chrome-vanadium steel with four bolts to each cap.

Lubrication is on the full-pressure system to the crankshaft, camshaft and connecting rod bearings. The oil pump is of the gear type and has a large

removable strainer. There is an oil-level cock and a dip stick for checking the level.

The radiator is of the built-up type with gilled tubes, header and bottom tanks, the header being of cast aluminium, fluted and polished.

Three-point suspension is employed for the engine, clutch and gearbox unit, the front support being a circular bearing, whilst at the rear the clutch chamber arms are carried on brackets and bolted to the frame side members, connection between the arms and the brackets being by spring-loaded bolts, which allow a certain amount of give to resist the torque at starting. The power is conveyed through a clutch of the multiple dry-disc type, totally enclosed, but with a cover for inspection and adjustment.

The standard gearbox gives ratios of : Top, direct; third, 1.76 to 1; second, 2.84 to 1; first, 5.35 to 1; reverse, 6.25 to 1; but with the optional equipment of a three-speed gearbox the ratios are : Top, direct ; second, 225 to 1 ; first, 4.8 to 1; reverse, 8 to 1.

A two-piece propeller shaft with a self-aligning bearing at the centre and enclosed fork-and-pin type universal joints, takes the drive to the overhead worm of the Timken rear axle. This centre bearing prevents whip due to centrifugal force at high speeds.

Both brakes are equalized and operate in the rear-wheel drums.

The frame is of pressed-steel channel, slightly inswept before the dash, but otherwise straight. Cam and lever type gear is employed for the steering ; this, combined with the large wheel, makes it very light.

The road wheels are of the steel-disc type running on Timken roller borings, these bearings also being employed for the gearbox and the back axle. The minimum clearance when loaded is 10i ins., this being at the back axle, which feature, with the pneumatic tyres, renders the chassis particularly suitable for Colonial work.

Much attention has been paid to springing, the springs being of the semielliptic type at both ends. Those at the front are 42 ins. by 2+ ins., and those at the redr 50 ins. by 24. ins. These long springs go a good way towards ensuring

the smooth running to which we have already referred.

Twelve gallons of fuel can be carried in the tank, which is fitted on the dash. The controls consist of an accelerator, spark and throttle levers on the steering column, and centrally positioned brake and gear levers.

All these details apply to the 2-ton model D. In the 30-cwt. model C, a worm-driven axle of a different type is utilized, and a three-speed gearbox is fitted as standard. In the 50-cwt. model F there is a more powerful engine of 4in. bore and 5i-in. stroke, and a heavier axle of Timken make.

As regards the main dimensions and prices, these are as follow :-30-cwt wheelbase, 11 ft. 3 ins. ; the price, on solid tyres, being 1370, with 112 10s. extra for semi-pneumatics, and 125 extra for giant pneumatics. 2-ton model : wheelbase, 12 ft. 9 ins.; price, on solid tyres, £395, with 118 10s. and £30 extra respectively for semi-pneumatics and giant pneumatics. 50-cwt. model : wheelbase, 14 ft. ; price, on solids, 1445, on semi-pneumatics 125 extra, and 145 extra for giant pneumatics.