THE YANKS ARE COMING

Page 38

Page 39

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

could provide big opportunities for small haulage companies and owner-drivers.

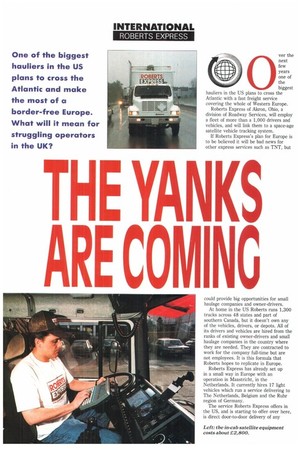

At home in the US Roberts runs 1,300 trucks across 48 states and part of southern Canada, but it doesn't own any of the vehicles, drivers, or depots. All of its drivers and vehicles are hired from the ranks of existing owner-drivers and small haulage companies in the country where they are needed. They are contracted to work for the company full-time but are not employees. It is this formula that Roberts hopes to replicate in Europe.

Roberts Express has already set up in a small way in Europe with an operation in Maastricht, in the Netherlands. It currently hires 17 light vehicles which run a service delivering to The Netherlands, Belgium and the Ruhr region of Germany.

The service Roberts Express offers in the US, and is starting to offer over here, is direct door-to-door delivery of any goods. Vehicles do not divert to pick up other loads and price is worked out on distance travelled. Once goods are on a truck they are not taken off until they reach their destination.

Scheduling is guaranteed to within 15 minutes and if a load is going to be late the customer is told. If it is two hours late the bill is cut by 25%. If it is four hours late the bill is halved.

Vehicles can be tracked via the Qualcomm satellite system to within 300 metres, so the customer always knows where his load is. This is done automatically every few minutes.

The Qualcomm satellite system has been up and running in the US for some years and is actively used by its transport industry. However, it is only just coming on the market in Europe. Roberts Express plans to be one of the first to use it on a large scale; its 17 vehicles in Europe are currently being fitted with the equipment.

About 75% of Roberts Express's vehicles in the US are nine tonnes GVW or less, although it claims it will take any load, including hazardous goods. Most of its work is 1,000 to 2,000kg. "We operate where the work is," says John Callf, European managing director.

"We're not going to go out and compete dollar for dollar with the big transport companies. We're offering a fast, high quality service of a different kind. The heavier weight will come with growth and bigger contracts including just-in-time deliveries. It's the direct freight business where we come in."

Christopher Healy, vice-president of services at Roadway Services, claims that the firm's rates are up to 30% cheaper than US airfreight on distances of between 600 and 700 miles and that it is quicker below 800 miles or up to 1,000 miles where special handling is required.

To use Roberts Express, a customer calls a freephone number and details are noted such as the type, size and timesensitivity of the load. A complicated computer system matches the freight to the right vehicle and a correctly qualified driver. There are different services on offer including a "White Glove" one for goods which require special care.

Roberts Express recruits not only existing hauliers to operate its services but also "entrepreneurs", people who are entering the business for the first time.

European hauliers which are interested in working for Roberts Express must be prepared for an initial financial outlay. They must have their own vehicle, and pay for the satellite equipment needed in their cab. This comes in the form of a hand-held keyboard and display unit, a black box controller and a fruit bowl-size antennae, which all costs about £2,800. It can be bought or leased.

The equipment takes two to four hours to install and requires about one hour's

instruction. It can also include a pocket pager to alert the driver of an in-coming message. Roberts Express pays for all the running costs. Healy claims that in the US, hauliers which switch to working for the company enjoy 10% more loaded miles than the national average. This more than pays back the cost of the equipment in about 18 months. The haulier is paid by Roberts Express for the loads that it carries, and is in turn directly paid by the customer. Roberts Express will give hauliers automatic bank credit for half of the cost of the job if it is high.

French and Italian hauliers will be the next to be offered full-time work by Roberts Express in Europe. The company plans to expand its vehicle fleet in the Netherlands to about 50 and take on 30 more in France. Calif says Roberts will expand to the UK, Spain and Denmark by the end of 1993.

LI by Danny Coughlan

• Last year the EC's legislative council revamped the regs governing drawbar dimensions, opting for an 18.35m overall length with a 16m loadbed and a minimum 350mm gap 'mixt truck and trailer'.

The EC's motive was praiseworthy enough: it was attempting to do away with the ultra-short cabs which some operators have specified to maximise drawbar load-length, at the expense of driver comfort.

But there was much wringing of hands among operators of those narrow-cabbed, close-coupled drawbars which seemed destined for virtual obsolescence after 1999. Since then the advent of high-cube 'jumbo' semi trailers has taken the spotlight away from drawbar developments (CM 5-11 March). After all, 101m from an artic is not to be sneezed at, particularly for ferry trips where a 16.5m artic travels considerably cheaper than an 18.35m drawbar rig.

Dutch chassis engineer Estepe of Heesch, near Nijmegen, has been playing an active role in this process. At the recent Amsterdam Show it launched a hydraulically elevating fifth-wheel coupler designed to allow tractors with low (950mm) chassis to haul standard or jumbo semis.

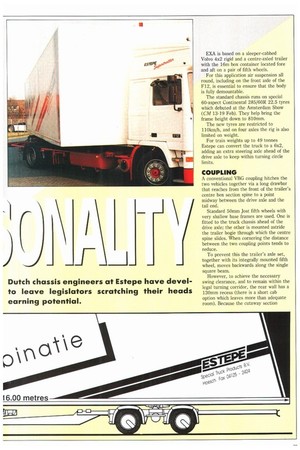

But now Estepe has gone further by blurring the boundary between artics and drawbars with EXA — an 18.35m drawbar chassis-cab and centre-axled trailer — but carrying a single 16m container offering 121m3 of cube.

Claimed advantages over a conventional outfit with two swap bodies include quicker through-loading operation, the absence of a gap between two bodies and the necessary shuttered openings.

With 20% more payload a fleet haulier can carry the equivalent of five jumbo semitrailers in four Estepe EXA rigs, and in the case of a reefer box there is only the one fridge unit to buy.

The design was developed in consultation with a group of Belgian fleet operators, and the EXA prototype has been attracting a lot of interest from highvolume hauliers such as the many Dutch flower specialists.

Dutch type approval is expected soon and then Estepe will start producing more pre-production models to be assessed by a number of interested parties. EXA is based on a sleeper-cabbed Volvo 4x2 rigid and a centre-axled trailer with the 16m box container located fore and aft on a pair of fifth wheels.

For this application air suspension all round, including on the front axle of the F12, is essential to ensure that the body is fully demountable.

The standard chassis runs on special 60-aspect Continental 285/60R 22.5 tyres which debuted at the Amsterdam Show (CM 13-19 Feb). They help bring the frame height down to 810mm.

The new tyres are restricted to 110km/h, and on four axles the rig is also limited on weight.

For train weights up to 49 tonnes Estepe can convert the truck to a 6x2, adding an extra steering axle ahead of the drive axle to keep within turning circle limits.

COUPLING

A conventional VBG coupling hitches the two vehicles together via a long drawbar that reaches from the front of the trailer's centre box section spine to a point midway between the drive axle and the tail end.

Standard 50mm Jost fifth wheels with very shallow base frames are used. One is fitted to the truck chassis ahead of the drive axle; the other is mounted astride the trailer bogie through which the centre spine slides. When cornering the distance between the two coupling points tends to reduce.

To prevent this the trailer's axle set, together with its integrally mounted fifth wheel, moves backwards along the single square beam.

However, to achieve the necessary swing clearance, and to remain within the legal turning corridor, the rear wall has a 130mm recess (there is a short cab option which leaves more than adequate room). Because the cutaway section interferes with Volvo's standard bunk arrangement Estepe, which also specialises in cab conversions, has added a twin-bedded top sleeper pod. To use this the second crew member has to squeeze up into the forward area to lower the rear bed into place.

Together with the swing clearance the bogie's rearward movement allows the EXA combination to meet the legal turning requirements.

Any lateral rolling movement from the body on bends is restricted by a pair of large steel rollers mounted on to the bogie frame. Running freely against the floor's steel belly plate, they absorb much of the stresses on the fifth wheel and on the container deck. A small clearance ensures that while travelling along straight roads they carry no load.

The 16m container on the EXA prototype is a Panolite-sided, self-supporting box with a 60mm steel sandwich floor.

The front is tapered upward slightly to accommodate bumps in the road; its roof is 20mm thick and a pair of doors are fitted at the rear. The container weighs in at just under five tonnes. It dismounts for loading/unloading using the air suspension on to six detatchable support legs which stow against the truck chassis when not in use.

The steel-plated decking will accept roller conveyors, enabling the container to accommodate five air-freight pallets.

As Estepe's patented concept progresses it intends to develop tilt and insulated/refrigerated versions. The reefers will have slightly reduced volumes due to their 100/120mm-deep flooring. The company is not a bodybuilder so it

aims to allow others manufacturers to produce the system under licence.

The concept can also be adapted to suit 13.71, 14.63 or 15.85m (45/48/52ft) sea containers or, with the turntables removed from the chassis and the bogie locked into the central position, it can handle standard swap bodies. Standard ISO twistlocks are fitted to the truck chassis and the trailer will have a special sub-frame for the purpose.

On the road the outfit moves with comparative ease. The trailer follows correctly within narrow lanes so the EXA is able to negotiate roundabouts or traffic lights without complication.

According to Estepe the outfit can pivot to 90° if necessary — watching it turn on full lock takes some believing, especially by other road users.

As it moves on full swing there is exaggerated movement as the cab's back wall passes close to the inside front edge of the box. Of course, like any turning combination, the driver is unable to see down the outside; in this case the body's front corner, drive axle, drawbar and hook all appear to swing out wide. On the inside curve the drive axle moves under the angled body as the rear bogie slides to the rear and pivots, to leave the rearmost

wheel and undemm bar peeping out at 450.

Unusual though it may be, the system certainly seems to work. Having patented the design, built the prototype and entered it for type approval, Estepe is not merely tilting at windmills.

The EXA weighs 15 tonnes in its dry freight format and costs about the same as a conventional drawbar outfit — but it lays the interpretation of the current 91/60/EEC directive wide open.

Instead of accepting that the 16m body length should comprise two bodies with a gap of at least 350min between them, Estepe believes that under the present EC regulation, the phrase the distance between the rear of the drawing vehicle and the front of the trailer" means no more than that.

Under this interpretation of the regulations the 350mm minimum clearance is easily maintained.

As fax as the UK is concerned, it is questionable if the EXA could be classified as a drawbar, as it appears to meet the essential criteria of an artic.

In the C&U regs an articulated vehicle is defined as a heavy motor vehicle with a trailer attached so that part of the trailer is superimposed on to the drawing vehicle, and with the trailer uniformly loaded not less than 20% of the weight of its load is born by the drawing vehicle.

By this definition it could be argued that Estepe's EXA is an artic outfit, which would therefore attract a much higher rate of VED.

However, the Dutch are more amenable towards well engineered transport systems and the EXA may well be approved there, allowing it to operate into the UK from a base in Holland.

We will have to wait and see how Estepe handles the thorny problem of European Whole Vehicle Type Approval — but if, as seems likely, Estepe wins type approval on its home territory, the high-cube EXA combination may well prove a winner.

0 by Bryan Jarvis