Passing Comments

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

False Panels for Lettering

G000 publicity matter on lorries and vans is valuable, but sometimes it is either necessary or advisable, according to the circumstances, that it should be changed• at short notice. If the wording or designs are painted on, the expense may be considerable and time wasted. A simple way out of this difficulty, which was seen recently on a lorry with a light-metal body, is to fit over the panels at the sides and rear, false panels of 10 s.w.g. light alloy held by spigots, secured to them, which are inserted into rubber bushes in metal carriers; these being permanently secured to the body. These fastenings are of the type used for holding back van doors against the body sides. The outer plates can be mounted or removed in a matter of seconds and can, of course, be used whether or not there is lettering, etc., beneath them. The idea might appeal to operators who let out vehicles on contract hire. Care must, of course, be taken that the additional weight, which is not excessive, does not bring the vehicle into a higher licensing category, or possibly raise its unladen weight above the 3-ton limit and thus reduce its speed to 20 m.p.h.

A32

N,o "Bleeding" Tyres

DESPITE warnings issued by tyre manufacturers, many drivers of vehicles, particularly in the heavier classes, make a habit of " bleeding " their tyres during long journeys. It is well known that if a tyre be at the maker's recommended pressure before the start of a run, the heat generated when the load is heavy and the vehicle seldom stops, is sufficient to build up pressure to an extent which may worry a conscientious driver who happens to test his tyres en route. He may then reduce the pressure to what it was at the start. This is a serious mistake because the manufacturers make due allowance for such an increase, which is almost a matter of self-protection on the part of the tyre. It is partly the flexing of the tyre which causes 'the heat and when the pressure rises this action is reduced, so that the temperature and pressure seldom rise beyond what may be termed a balancing point. Reduction of the additional pressure would, however, cause further heat. Apart from this, slow running or other conditions occurring for a time may permit the tyres to cool, when the pressure falls below the correct limit and serious damage can then be done.

Clever Method of Tyre Repairing

WHEN witnessing a recent demonstration of the Bowes Seal Fast method of puncture repairing, a representative of this journal was almost under the impression that he was being treated to a display of magic. In the Bowes process no solution is used, neither is the patch material unduly tacky when the protective linen has been stripped off. The tube in the area of the puncture is first roughened, Bowes fluid is then brushed on and the patch applied.

Although the patch seals immediately it is not 100 per cent. effective until the tyre has been run for some lime. The reason is that the heat generated in the lyre has the effect of finishing off the sealing process. It is quite impossible to remove a Bowes patch.

Outer covers can also be effectively treated, and several examples which were examined showed that the patching and the casing had become homogeneous.

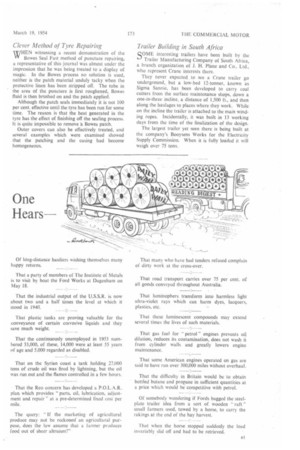

Trailer Building in South Africa

gomE interesting trailers have been built by the 1.-) Trailer Manufacturing Company of South Africa, a branch organization of J. H. Plane and Co., Ltd., who represent Crane interests there.

They never expected to see a Crane trailer go underground, but a low-bed 12-tonner, known as Sigma Sannie, has been developed to carry coal cutters from the surface maintenance shons, down a one-in-three incline, a distance of 1,500 ft., and then along the haulages to places where they work. While on the incline the trailer is attached to the main winding ropes. Incidentally, it waS built in 13 working days from the time of the finalization of the design.

The largest trailer yet seen there is being built at the company's Booysens Works for the Electricity Supply Commission. When it is fully loaded it will weigh over 75 tons.