SEATING 60 PASSE ERS IN A SINGLE-DECKER

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

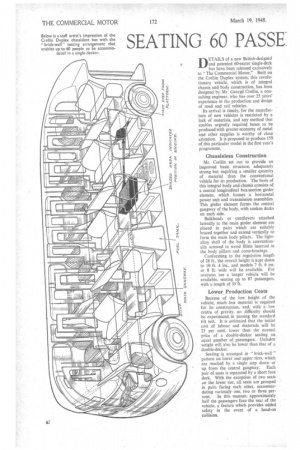

Tiered Seating in Chassisless Bus Increases Accommodation and Reduces Overall Height. Big Savings in Manufacturing and Operating Costs are Expected DETAILS of a new British-designed and patented 60-seater single-deck bus have been released exclusively to " The Commercial Motor." Built on the Crellin Duplex system, this revolutionary vehicle, which is of integral chassis and body construction, has been designed by Mr. George" Crellin, a consulting engineer, who has over 25 years' experience in the production and design of road and rail vehicles.

Its arrival is timely, for the manufacture of new vehicles is restricted by a lack of materials, and any method that enables urgently required buses to be produced with greater economy of metal and other supplies is worthy of close attention. It is proposed to produce 150 of this particular model in the first year's programme.

Chassisless Construction Mr. Crellin set out to provide an improved basic structure, adequately strong but requiring a smaller quantity of material than the conventional vehicle for its production. The basis of this integral body and chassis consists of a central longitudinal box-section girder element, which houses a horizontal power unit and transmission assemblies. This girder element forms the central gangway of the body, with sunken decks on each side.

Bulkheads or cantilever; attached laterally to the main girder element are placed in pairs which are suitably braced together and extend vertically to form the main body pillars. The lightalloy shell of the body is conventionally screwed to wood fillets inserted in the body pillars and cross-bracings.

Conforming to the regulation length of 28 ft., the overall height is kept down to 10 ft. 4 ins., and models 7 ft. 6 ins, or 8 ft. wide will be available. For overseas use a longer vehicle will be available, seating up to 87 passengers. with a length of 39 ft.

Lower Production Costs

Because of the low height of the vehicle, much less material is required for its construction, and, with a low centre of gravity, no difficulty should be experienced in passing the standard tilt test. It is estimated that the initial cost of labour and materials will be 25 per cent, lower than the normal price of a double-decker seating an equal number of passengers. Unladen weight will also be lower than that of a double-decker.

Seating is arranged in "brick-wall" pattern on lower and upper tiers, which are reached by a single step down or up from the central gangway. Each pair of seats is separated by a short foot deck. With the exception of two seats on the lower tier, all seats are grouped in pairs facing each other, accommodating variously one, two or three per

sons. In this manner, approximately half the passengers face the rear of the vehicle, a feature which provides added safety in the event of a head-on collision. A minimum spacing of 1 ft. 7 ins, is maintained between the squabs of facing seats, and there is a large window

for each pair of seats. The superimposed upper and lower seats are supported on the central gangway side by stout tubular continuous members extending between the roof of the vehicle and the sunken decks. These members are bent to delineate the seat backs, cushions and risers.

Minimum headroom throughout the Crellin Duplex body is 5 ft. 10 ins.; which is the distance between the roof and upper-tier flooring. This is at least equal to the headroom of a standard double-deck bus and the headroom in the gangway and lower tier of the new body is considerably greater.

Because of the low height and small frontal area, this design offers less wind resistance, which, in conjunction with the low weight, should provide an improved fuel consumption. Acceleration, braking, tyre wear and all-round performance should accordingly be much improved.

Crellin Duplex bodies with " brickwall " seating arrangements can be adapted to existing single-decker chassis. Seating capacity would be raised from 32 to 53 passengers and the passengers would benefit by the widerspaced seating than can be obtained in the standard 32-seater body.

In comparing the specification of a double-decker chassis and a singledecker chassis fitted with a 53-seater Crellin Duplex body, a weight reduction of 12 per cent. is expected. Fuel consumption might be reduced by 20 per cent. and acceleration improved by 10 per cent. Using a standard 125 b.h.p. engine, the weight per passenger would be 407 lb. and the power-weight ratio 0.64 b.h.p, per cwt. of gross load.

There have been few alterations to the original design, one of the first modifications being to provide a screen between the passengers on the lower and upper tiers. Some criticism was levelled at the narrow inter-floor step of the initial design. This has since been changed to provide one which will be as safe in operation as the normal staircase of a double-decker.

A further criticism was raised, by a well-known operator, of the reduced advertising space on the exterior of the body, but this is a small item, and, in any case, the advertising space is greater in area than that of a standard singledeck bus.

The Crellin Duplex body, which has already crewed considerable interest on the Continent, is being manufactured Through the Crellin agent, Manalla and Co., Cecil House, 41, Charing Cross Road, London, W.C.2.