At Last—A Satisfactory Aluminium Solder

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

AN easily fusible metal for soldering aluminium and its alloys has been introduced by Alunize, Ltd., 34, North Street, Rugby. Bearing the same name as its maker, this preparation is available in two types, one with a melting point of 180 degrees C.—about that of ordinary soft solder—and the other fusible at 220 degrees C.

In the past, no aluminium solder that was entirely satisfactory has come to our knowledge. Accordingly, the introduction of Alunize is of considerable importance, and is likely to have a big influence upon aluminium usage. In the light of past experience scepticism is naturally felt with regard to the claims made for this product. Therefore, we have ourselves carried out a rough but reliable test. A sketch shows the simple method adopted.

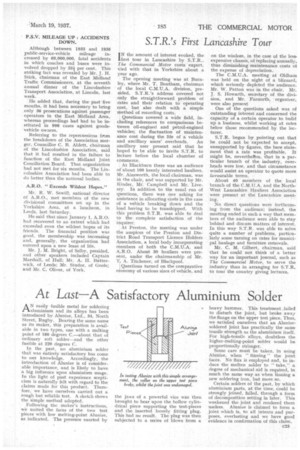

Following the maker's instructions, we united the faces of the two test pieces with low melting-point Alunize, as indicated. The pressure exerted by the jaws of a powerful vice was then brought to bear upon the hollow cylindrical piece supporting the test-pieces and the inserted loosely fitting plug. This had no result. The plug was then subjected to a series of blows from a heavy hammer. This treatment failed to disturb the joint, but broke away the flange on the upper test piece. Thus, we satisfied ourselves that an Alunizesoldered joint has practically the same tensile strength as the aluminium itself. For high-tensile alloys, doubtless the higher-melting-point solder would be proportionally stronger.

Some care must be taken, in using Alunize, when " tinning " the joint faces. No flux is employed and, to induce the molten solder to " take," a degree of mechanical aid is required, in much the same way as when tinning a new soldering iron, but more so.

Certain solders of the past, by which aluminium parts, at the time, could be strongly joined, failed, through a form of decomposition setting in later. This weakened the -joint and rendered them useless. Alunize is claimed to form a joint which is. to all intents and purposes, everlasting and we have good evidence in confirmation of this claim.