Tony looks first at cab ergonomics

Page 63

Page 65

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

IF there is a perfect vehicle from the driver's point of view I have not yet found it. Design gets better all the time but there is usually some way in which improvement is possible even if it is simply a matter of selecting particular options available for a model to alter the basic specification. There is usually nothing one can do about the basic mechanical characteristics of a chassis to improve the lot of the driver and the model will be selected bearing this in mind if the best results are required.

It goes without saying that steering must be sufficiently light in relation to the weight of the vehicle or outfit, brakes must be responsive to give satisfactory retardation, the clutch must not require excessive physical effort to operate and that all pedals and controls must be conveniently placed in relation to the driver's seat so that he does not have to adopt awkward or pain-inducing positions for any part of his legs or arms. All this comes under the general heading of "ergonomics" and nowadays much more of this science is being applied to commercial vehicles to make them lesss tiring to drive.

However, there are other ways in which fatigue can be produced and it is quite amazing how different one vehicle can be from another even though the "basic ergonomicsare apparently identical.

Heavy controls make a driver physically tired but noise can have a greater effect on his general condition. High levels of noise for long periods can be extremely wearing and produce a feeling of tiredness, sometimes more easily than pure physical exertion. And it is not just a question of the decibel count, the effect being dependent to a great extent on the type of noise—whether it is high pitched or of low frequency for example.

Much depends on the inherent noisiness of the power unit but the position can be improved by adding extra insulation to any that is fitted as standard in a cab. It is of little value having an old army greatcoat or a couple of blankets lying over the engine cover. Properly fitting insulated engine covers are obtainable which do the job much better.

It is riot only the engine cover area which needs looking at. Noise plays funny tricks and it is often worth while applying insulation under the floor and behind the scuttle and dash panels. It can also pay to lay sound-absorbing material under the roof (between the metal and lining if one is fitted) and to the back panel to stop noise that does enter from echoing around the interior and making matters worse.

Anything that can be done to reduce noise level is a good investment in reducing driver fatigue and therefore improving safety. The same can be said for seating. A driver who has to change his position continually because of hard cushions or a badly designed seat is having his concentration on driving impaired. And if there is inadequate adjustment available a driver may not be able to get to a comfortable position at all.

Much has been done in recent years to improve seat design and for that matter general cab mountings. Nothing is worse than having to sit in one position for a whole working day being bounced about on a seat with one's back continuously slapped by the backrest. Fully adjustable seat bases with backrests that allow rake alteration are now available and ''suspension" seats with spring or torsion-bar systems are gaining in popularity. These really do prevent vibration from being transmitted to the driver although it is important that adjustment should be available to cater for all weights of driver.

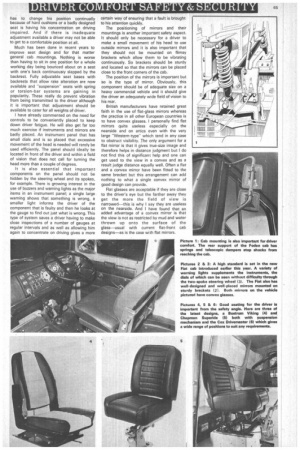

I have already commented on the need for controls to be conveniently placed to keep down driver fatigue. He will also get far too much exercise if instruments and mirrors are badly placed. An instrument panel that has small dials and is so placed that excessive movement of the head is needed will rarely be used efficiently. The panel should ideally be located in front of the driver and within a field of vision that does not call for turning the head more than a couple of degrees.

It is also essential that important components on the panel should not be hidden by the steering wheel and its spokes, for example. There is growing interest in the use of buzzers and warning lights as the major items in an instrument panel; a single large warning shows that something is wrong, a smaller light informs the driver of the component that is faulty and then he looks at the gauge to find out just what is wrong. This type of system saves a driver having to make close inspections of a number of gauges at regular intervals and as well as allowing him again to concentrate on driving gives a more certain way of ensuring that a fault is brought to his attention quickly.

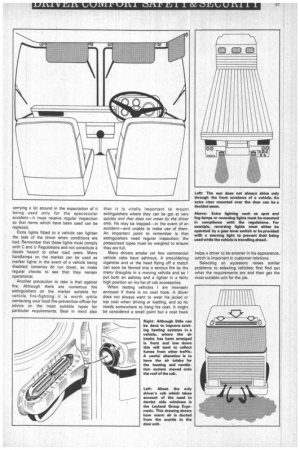

The positioning of mirrors and their mountings is another important safety aspect. It should only be necessary for a driver to make a small movement of his head to use outside mirrors and it is also important that they should not be mounted on flimsy brackets which allow them to be vibrating continuously. So brackets should be sturdy and located so that the mirrors can be placed close to the front corners of the cab.

The position of the mirrors is important but So is the type of mirror. Obviously, this component should be of adequate size on a heavy commercial vehicle and it should give the driver an adequately wide field of vision to his rear.

British manufacturers have retained great faith in the use of flat-glass mirrors whereas the practice in all other European countries is to have convex glasses. I personally find flat mirrors quite useless especially on the nearside and on artics even with the very large 'Western-type" which tend in any case to obstruct visibility. The only argument for a flat mirror is that it gives true-size image and therefore helps in distance judgment but I do not find this of significant help and one can get used to the view in a convex and as a result judge distance equally well. Often a flat and a convex mirror have been fitted to the same bracket but this arrangement can add nothing to what a single convex mirror of good design can provide.

Flat glasses are acceptable if they are close to the driver's eye but the farther away they get the more the field of view is narrowed—this is why I say they are useless on the nearside. And I have found that an added advantage of a convex mirror is that the view is not as restricted by mud and water thrown up onto the surface of the glass—usual with current flat-front cab designs—as is the case with flat mirrors. BEFORE deciding on the accessories to be included in a cab specification with a view to driver wellbeing, it is essential to take account of the type of work on which the vehicle will be used. There is, for example, little advantage in the driver of a door-to-door delivery van having a suspension seat, and one should not even consider a cab completely devoid of sound-proofing for long-distance work.

What then can be done to ease the lot of the driver? It is quite easy, for instance, to make a boring job such as waiting for hours in dock queues less tedious by fitting a radio. A less obvious case is that of a lorry regularly making long journeys in a southerly direction during the late afternoon and early evening: the sun shining from the west or south-west will play relentlessly on the off-side of the cab and I would plump for an extra sun visor fitted over the door, were I handling a vehicle On this sort of service.

The safety angle of cab accessories should not be overlooked when considering their inclusion. For a great many years screen wipers have been a legal requirement. As with driving mirrors, I never cease to be surprised at the poorness of much of the equipment. Although one might consider that so long as a wiper works, that's good enough, in fact a considerable degree of fatigue is caused by badly situated wiping areas and by the irritating noise created by some units. It is not unusual for the wipers to be among the noisiest equipment in a modern vehicle.

On this subject I often wonder why we can only have two wipers. If the current craze for wrap-round screens is caused by the wish to provide the driver with better vision, then designers should accept the fact that in the UK it rains on SO days in every 100 and with two wipers only, most wrap-round screens are inadequately cleared where they are supposed to provide the extra vision.

We hear a lot today about tired drivers—legislation to reduce drivers' hours is derived directly from this problem. Cold contributes to tiredness yet often the cab heating and ventilation equipment is sadly skimped either through lack of space or in an effort to reduce costs. If drivers are to remain alert and reasonably comfortable, then heating and ventilation equipment must head the cab accessory priority list.

Spare a thought for the driver trapped in a traffic jam. The air conditioning units available are on the expensive side. And one cannot use them in congested conditions if the fresh air intake is situated so as to collect all the exhaust fumes.from other vehicles—a point to watch also with the heating equipment. Not to be forgotten when specifying this equipment is that other very important function—demisting. In. my opinion it is essential that every window through which the driver needs to be able to see while on the road can be kept completely clear of condensation at all times. One collision saved during the operating life of a vehicle will undoubtedly reimburse an operator for the

cost of a really efficient heater. /demister/ventilator.

The law requires the fitting of seat belts in vans not exceeding 30cwt unladen. And generally speaking I feel that if seat belts keep good men happy, then fit them!

Duties connected with lorries are hazardous so far as slight injuries go and many vehicles now carry first-aid kits. But it's no use

carrying a kit around in the expectation of it being used only for the spectacular accident—it must receive regular inspection so that items which have been used can be replaced.

Extra lights fitted to a vehicle can lighten the task of the driver when conditions are bad. Remember that these lights must comply with C and U Regulations and not constitute a dazzle hazard to other road users. Many handlamps on the market can be used as marker lights in the event of a vehicle being disabled; batteries do run down, so make regular checks to see that they remain operational.

Another precaution to take is that against fire. Although there are numerous fire extinguishers on the market suitable for vehicle fire-fighting it is worth while contacting your local fire-prevention officer for advice on the most suitable types for particular requirements. Bear in mind also

that it is vitally important to mount extinguishers where they can be got at very quickly and that does not mean by the driver only. He may be trapped—in the event of an accident—and unable to make use of them. An important point to remember is that extinguishers need regular inspection; the pressurized types must be weighed to ensure thay are full.

Many drivers smoke yet few commercial vehicle cabs have ashtrays. A smouldering cigarette end or the head flying off a match can soon be fanned into a serious fire by the many draughts in a moving vehicle and so I put both an ashtray and a lighter in a fairly high position on my list of cab accessories.

When testing vehicles I am intensely annoyed if there is no coat hook. A driver does not always want to wear his jacket or top coat when driving or loading, and so he needs somewhere to hang his coat. It might be considered a small point but a coat hook

helps a driver to be smarter in his appearance, which is important in customer relations.

Selecting an accessory raises similar problems to selecting vehicles: first find out what the requirements are and then get the most suitable unit for the job.