HINTS ON MAINTENANCE.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

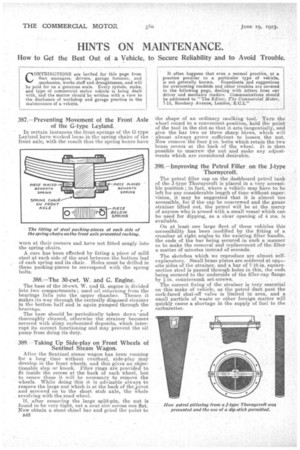

387.—Preventing Movement of the Front Axle of the G-type Leyland.

In certain instances the front springs of the G-type Leyland have worked loose in the spring chairs of the front axle, with the result that the spring boxes have worn at their corners and have not fitted snugly into the spring chairs.

A cure has been effected by fitting a piece of mild steel at each side of the seat between the bottom leaf of each spring and its chair. Holes must be drilled in these packing-pieces to correspond with the spring bolts.

388.—The 30-cwt. W. and G. Engine.

The base of the 30-cwt. W. and G. engine is divided into two compartments ; used oil returning from the bearings falls into the upper chamber. Thence it makes its way through the centrally disposed strainer in the bottom half and is again pumped through the bearings.

The base should; be ;periodically -taken down and thoroughly cleaned, otherwise the strainer becomes covered with slimy carbonized deposits, which interrupt its correct functioning and may prevent the oil pump from doing its duty.

389. —Taking Up Side-play on 'Front Wheels of Sentinel Steam Wagon.

After the Sentinel steam wagon has been running for a long time without overhaul, side-play may develop in the front wheels, and this gives an objectionable slap or knock. Fibre rings are provided to fit inside the recess at the back of each wheel, but to renew these it will be necessary to remove the wheels. While doing this it is advisable always to remove the large nut which is at the back of the_pivet and screwed on to the short stub axle, the whole revolving with the road wheel.

If, after removing the large split-pin, the nut is found to he very tight, cut a neat slot across one flat. Now obtain a stout chisel bar and grind the point to J342

the shape of an ordinary caulking tool. Turn the wheel round to a convenient position, hold the point of the tool in the slot so that it acts tangentially, and give the bar two or three sharp blows, which will almost always prove sufficient to loosen the nut. Now remove the four On. bolts which retain the two brass covers at the back of the wheel. It is then possible to unscrew the nut and make any adjustments which are considered desirable.

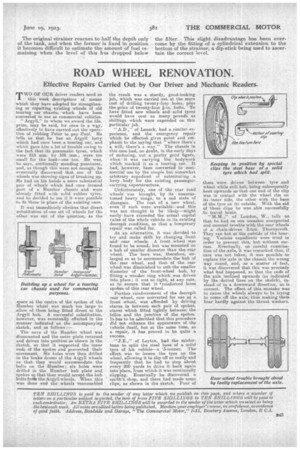

390.—Improving the Petrol Filler on the I-type Thornycroft.

The petrol filler cap on the dashboard petrol tank of the ..1--type Thornyeroft is placed in a very accessible position ; in fact, where a vehicle may have to be left for any considerable length of time without supervision, it may be suggested that it is almost too accessible, for if the cap be unscrewed and the gauze strainer lifted out, the petrol will be at the mercy of anyone who is armed with a small vessel which can be used for dipping, as a clear opening of 4 ins, is available.

On at least one large fleet of these vehicles this accessibility has been modified by the fitting of a crossbar at right angles to the existing filter handle, the ends of the bar being secured in such a manner as to make the removal and replacement of the filter a matter of minutes instead of seconds.

The sketches which we reproduce are almost selfexplanatory. Small brass plates are soldered at opj,site sides of the strainer, and a bar of 7-16-in. equaresection steel is passed through holes in this, the ends being secured to the underside of the filler-cap flange by /-in. -countersunk set-screws.

The correct fixing of the strainer is very essential on this make of vehicle, as the petrol duet past the cork-faced shut-off valve is limited in area, and a small particle of waste or other foreign matter will quickly cause a shortage in the supply of fuel to the carburetter.

The original strainer reaches to half the depth only of the tank, and when the former is fixed in position it becomes difficult to estimate the amount of fuel remaining when the level of this has dropped below

the filter. This slight disadvantage has been overcollie by the fitting Df a cylindrical extension to the bottom of the strainer, a dip-stick being used to ascertain the correct level.