Makes Unit Changing Easier

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

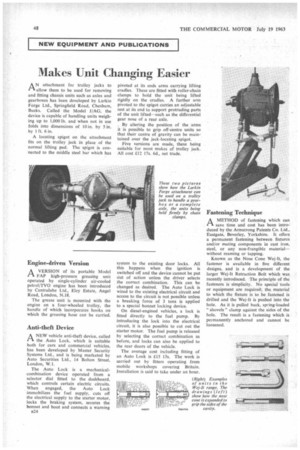

AN attachment for trolley jacks to allow them to be used for removing and fitting chassis units such as axles and gearboxes has been developed by Larkin Forge Ltd., Springfield Road, Chesham, Bucks. Called the Model PAG, the device is capable of handling units weighing up to 1,000 lb. and when not in use folds into dimensions of 10 in. by 5 in. by 1 ft. 6 in.

A locating spigot on the attachment fits on the trolley jack in place of the normal lifting pad. The spigot is connected to the middle steel bar which has pivoted at its ends arms carrying lifting cradles. These are fitted with roller-chain clamps to hold the unit being lifted rigidly on the cradles. A further arm pivoted to the spigot carries an adjustable rest at its end to support protruding parts of the unit lifted—such as the differential gear nose of a rear axle.

, By altering the position of the arms it is possible to grip off-centre units so that their centre of gravity can be maintained over the jack-locating spigot.

Five versions are made, these being suitable for most makes of trolley jack. All cost 12 I7s. 6d., net trade.