Play safe with by...).

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

protective elothhig

NEVER BEFORE have safety and worker protection been so much in the public eye as they are today_ The Health and Safety at Work Act 1974 affects everyone connected either directly or indirectly with a working situation_ . The Act is a wide-ranging piece of legislation with one important objective, namely to secure and protect the health, safety and welfare of people at 'work. .

It is the duty of all employers to ensure that the working environment systems, premises and equipment are all healthy and safe. The handling, storage .and transport of materials must be carried out safety, and those working on vehicles in workshops arid the drivers on the road must be adequately protected.

On the . other hand, employees must take all reasonable care to protect themselves and their colleagues. This includes wearing protective equipment and clothing supplied by the employer. The Health and Safety Executive has been formed under the Commission and is wsponsible with local authorities for enforcing the statutory requirements through its network of inspectors.

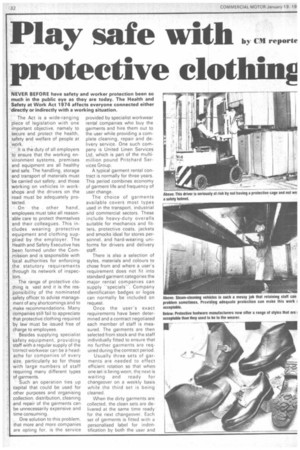

The range of protective clothing is vast and it is the responsibility of the nominated safety officer to advise management of any shortcomings and to make recommendations. Many companies still fail to appreciate that protective clothing required by law must be issued free of charge to employees.

Besides supplying specialist safety equipment, providing staff with a regular supply of the correct.workwear can be a headache for companies of every size, particularly so for those with large numbers of staff requiring many different types of garments.

Such an operation ties up capital that could be used for other purposes and organising collection, distribution, cleaning and repair of the garments can be unnecessarily expensive and time consuming.

One solution to this problem, that more and more companies are opting for, is the service provided by specialist workwear rental companies who buy the garments and hire them out to the user while providing a complete cleaning, repair and delivery service. One such company is United Linen Services Ltd, which is part of the multimillion pound Pritchard Services Group.

A typical garment rental contract is normally for three years. This period combines economy of garment life and frequency of user change.

The choice of garments available covers most types used in the transport, industrial and commercial sectors. These include heavy-duty overalls suitable for mechanics and fitters, protective coats, jackets and smocks ideal for stores personnel, and hard-wearing uniforms for drivers and delivery staff.

There is also a selection of styles, materials and colours to chose from and where a user's requirement does not fit into standard garment categories the major rental companies can supply "specials". Company identification badges or logos can normally be included on request.

Once the user's exact requirements have been determined and a contract negotiated each member of staff is measured. The garments are then selected from stock and the staff individually fitted to ensure that no further garments are required during the contract period.

Usually three sets of garments are needed to effect efficient rotation so that when. one set is being worn, the next is waiting and ready for changeover on a weekly basis while the third set is being cleaned.

When the dirty garments are collected, the clean sets are delivered at the same time ready for the next changeover. Each set of garments is fitted with a personalised label for indentification by both the user and rental company. This normally contains the user company's name, the employee's name, and a series of codes relevant to the administrative -documentation for the processing of the set.

If a garment requires repair at any time this is carried out automatically as a result of a checking procedure during the cleaning phase of rotation.

Barring mishaps that damage garments beyond repair or other problems that may occur to upset the rotation of sets, most major rental companies can claim that their service is both cost-effective and troublefree.

There is a continuing upward trend for the specialist garment rental company services, which is no doubt indicative that they are an acceptable alternative to in-house provision of workwear.

Use of protective and safety footware by those engaged in the transport industry has rapidly increased now that the range of styles in shoes and boots can meet most tastes. These must be made to conform to BSI 1870 part 2 specification and many have benefited from the protection that they offer. The price is comparable with conventional footwear and usually available in a size range from 5 to 12. Head protection is of paramount importance whenever working in an area of injury risk. There is a vast range of safety helmets. on the market, but to ensure adequate pro-. tection they must be made to British Standard BS5240.

A range of "bump caps" is now available for use where helmets are not considered desirable. The degree of protection is obviously not the same as that for safety helmets but it meets British Standard BS5240.

Winter and wet weather working is always unpleasant, but many protective clothing manufacturers can offer a range of anoraks, over-trousers, jackets, smocks and long coats. These are usually made in nylon with PVC proofing, and quality is of prime importance. There are many cheap PVC versions but they harden in cold weather and tear easily.

For those handling loads necessitating hand protection there is a magnificent range of gloves from cotton and leather to rubber and PVC. Before purchase, however, it is necessary to confirm with the manufacturer that they are suitable for the job. Many transport companies are alarmed by the consumption of gloves by their staff and have failed to realise that the wrong type could be in use resulting in premature wear or chemical contamination.

Working at night can present safety problems because of poor visibility. Many garments incorporating reflective materials are available and full use of these is being made by ambulance, fire and police authorities. Night drivers should always be issued with at least one form of reflective garment for use in case of break-down or accident.

Eyes must be protected either by safety spectacles, goggles, face shield or fixed shields. For those who normally wear prescription spectacles, prescription safety specs can be fitted and supplied so long as they are the appropriate protection for the particular hazard in question. British Standard BS2092 is the standard governing 80 per cent of all eye protection equipment used in the UK. Inorder to ensure legal protection, always go for products suitably marked with this number.

Section 33 of the Health and Safety at Work Act 1974 lists many offences for which strict penalties can be applied. Perhaps the most serious is failing to fulfil the obligations of -the Act.