Impressions of

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

THE PAGEFIELD PLANTAGENE

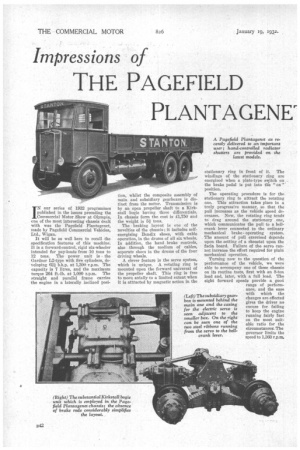

IN our series of 1932 programmes published in the issues preceding the Commercial Motor Show at Olympia, one of the most interesting chassis dealt with was the Pagefield Plantagenet, made by Pagefield Commercial Vehicles, Ltd., Wigan.

It will be as well here to recall the specification features of this machine. It is a forward-control, rigid six-wheeler intended for pay-loads from .10 tons to 12 tons. The power unit is the llardner L2-type with five cylinders' developing 6212 b,h.p. at 1,300 r.p.m. The capacity is 7 litres, and the maximum torque 264 ft-lb. at 1,000 r.p.m. The straight and parallel frame carries the engine in a laterally inclined posi

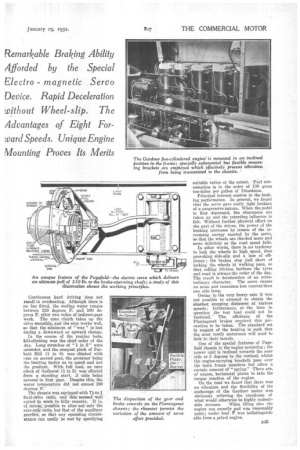

tion, whilst the composite assembly of main and subsidiary gearboxes is distinct from the motor. Transmission is by an open propeller shaft to a Kirk. stall bogie having three differentials. In chassis form the cost is £1,750 and the weight is5,4 tons. The braking layout is one of the novelties of the chassis; it includes selfenergizing Bendix shoes, with cable operation, in the drums of all six wheels. In addition, the hand brake controls, also through the medium of cables, separate shoes in the drums of the four driving wheels. A clever feature is the servo system, which is unique. A rotating ring is mounted upon the forward universal of the propeller shaft. This ring is free to move axially to a limited extent when it is attracted by magnetic action in the stationary ring in front of it. The windings of the stationary ring are energized when a plate-type switch on the brake pedal is put into the " on " position.

The operating procedure is for the stationary ring to attract the rotating one. This attraction takes place in a truly progressive manner, so that the pull increases as the vehicle speed decreases. Now, the rotating ring tends to drag around the stationary one, which communicates the pull to a bellcrank lever connected to the ordinary mechanical brake operating system. The amount of pull exercised depends upon the setting of a rheostat upon the facia board. Failure of the servo cannot increase the effort required for plain mechanical operation.

Turning now to the question of the performance of the vehicle, we were able to accompany one of these chassis on its routine tests, first with an 8-ton load and, later, with a full load. The eight forward speeds provide a good range of performance, and the ease with which the changes are effected gives the driver no excuse for failing to keep the engine running fairly fast on the most suitable ratio for the circumstances. The governor limits the speed to 1,360 r.p.m. (Left) The subsidiary gearbox is mounted behind the main one and the casing for the electric servo is seen adjacent to the smaller box. On the right can be seen one of the two steel ribbons running from the servo to the bell. crank lever. Continuous hard driving does not result in overheating. Although there is no fan fitted, the cooling water ranges between 130 degrees F. and 160 degrees F. after two miles of indirect-gear work. The cone clutch takes up the drive smoothly, and the stop works well, so that the minimum of " way " is lost during a downward or upward change.

In the course of the routine tests, hill-climbing was the chief order of the day. Long stretches of "1 in 8" were ascended, and the steepest pitch of Parhold Hill (1 in 6) was climbed with ottse on second gear, the governor being the limiting factor as to speed and not the gradient With full load, an easy climb of Gathutst (1 in 5) was effected from a standing start, .3 mile being covered in first gear. Despite this, the water temperature did not exceed 160 degrees F.

The chassis 'was equipped with 71-to-1 final-drive ratio, and this seemed well suited to work in hilly country. It is, of c‘ourse, possible to alter not only the rear-rtste ratio, but that of the auxiliary gearbox, so that any operating circumstance can easily be met by specifying

suitable ratios at the outset Fuel consumption is in the order of 130 gross ton-miles per gallon of Diesoleum. Principal interest centres in the brak '

in°. found performance. In general, we fod that the servo gave really light braking of a progressive nature. When the pedal is first depressed, the clearances are taken up and the retarding influence is felt. Without further physical effort on the part of the driver, the power of the braking increases by reason of the increasing energy exerted by the servo, so that the wheels are checked more and more definitely as the road speed falls.

In other words, there is no tendency to lock the wheels it high speed, thus provoking side-slip and a loss of efficiency; the brakes stop just short of locking the wheels fit walking pace, so that rolling friction bettken the tyres and road is always the order of the day. The result is deceleration of an extraordinary character. The servo causes no noise and consumes less current than one side lamp.

Owing to the very heavy rain it was not possible to attempt to obtain the shortest stopping distances at various speeds; furthermore, at the time in question the test load could not be fastened." The efficiency of the Plantagenet brakes required this precaution to be taken. The standard set in respect of the braking is such that the most costly motorcars will need to loek to their laurels.

One of the special features of Pagefield chassis is 'the engine mounting ; the power Unit is inclined towards the near side at .5 degrees to the vertical, whilst the-engine-carrying brackets pass over the main frame members but allow a certain amount of "spring." There are, of course, horizontal plates to take the torque reaction of the -engine. On the road we found that there was no vibration and the flexibility of the anchorage of the Gardner motor was obviously relieving the crankcase of what would otherwise be highly undesir

able stresses. When idling also the engine ran sweetly and was reasonably quiet ; under load iT. was indistinguishable from a petrol engine.