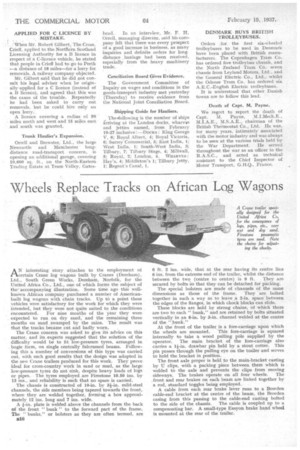

Wheels Replace Tracks on African Log Wagons

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

AN interesting story attaches to the employment of certain Crane log wagons built by Cranes (Dereham), Ltd., South Green Works, Dereham, Norfolk, for the United Africa Co., Ltd., one of which forms the subject of the accompanyingillustration. Some time ago this wellknown African company purchased a number of Americanbuilt log wagons with chain tracks. Up to a point these vehicles were satisfactory for the work for which they were intended, but they were not quite suited to the conditions encountered. For nine months of the year they were expected to run on dry sand, and the remaining three months on sand swamped by the rains. The result was that the tracks became cut and badly worn.

The Crane concern was asked to give its advice on this matter, and its experts suggested that the solution of the difficulty would be to fit low-pressure tyres, arranged in bogie form, on single centrally fulcrumed beams. Following this a number of conversions of this type was carried out, with such good results that the design was adopted in the new Crane trailers produced for this work. They prove ideal for cross-country work in sand or mud, as the large low-pressure tyres do not sink, despite heavy loads of logs or pipes. The tyres employed are Firestone 10.50 ins. by 13 ins., and reliability is such that no spare is carried.

The chassis is constructed of 10-in. by 2k-in, mild-steel channels, the side members being tapered towards the front, where they are welded together, forming a box approximately 12 ins, long and 7 ins. wide.

A Fin, plate is welded above the channels from the back of the front " bunk " to the forward part of the frame. The "bunks," or bolsters as they are often termed, are

3316

6 ft. 2 ins, wide, that at the rear having its centre line 6 ins. from the extreme end of the trailer, whilst the distance between the two (centre to centre) is 9 ft. They am secured by bolts so that they can be detached for packing.

The special bolsters are made of channels of the same dimensions as those of the frame. They are bolted together in such a way as to leave .a 24n. space' between the edges of the flanges, in which chock blocks can slide.

These blocks are held by strong chains, of which' there are two to each " bunk," and are retained by bolts situated vertically in an 8-in. by 3-in, channel welded at the centre of the "hunk."

At the front of the trailer is a fore-carriage upon which the wheels are mounted. This fore-carriage is squared internally to take a wood pulling pole supplied by the operator. The main bracket of the fore-carriage also carries a Win. drawbar pin held by a stout cotter. This pin passes through the pulling eye on the trailer and serves to hold the bracket in position.

The front axle proper is held to the main-bracket casting by U clips, with a packing piece between them which is welded to the axle and prevents the clips from moving sideways. The brakes operate on all four wheels. The front and rear brakes on each beam are linked together by a rod, standard toggles being employed. • A cable from each rear brake lever runs to a Bowden cable-end bracket at the centre of the beam, the Bowden casing from this passing to the cable-end casting bolted to the side of the chassis. The cable is coupled up to a compensating bar. A small-type Easyon brake hand wheel is mounted at the rear of the trailer.