BRAKING THE HIGH-SPEED VEHICLE.

Page 138

Page 139

If you've noticed an error in this article please click here to report it so we can fix it.

HOW Progress in Brake Design has Increased the Safety of all Types of Passenger-carrying Vehicle.

COMPAlelSONS are odious, but when one is reviewing progress in the design of anything mechanical it is absolutely, essential that the latest attainments in the scientific world be compared with those of the past. Much hasbeen: written about the development of the passengercarrying vehicle from the points of eiew of comfort and performance, this latter feature usually being confined very larg.edy to the power, speed and accelerating proclivities of the .engine.; but very little has been said, however, anent the great. strides that have been made in the retarding mechanism which has had such an effect on the general eafety of road transport. If the modern vehicle, with its high-speed, high-powered engine, were to be equipped with a 10-year-old braking system the result would be calamitous, a.s anyone eau well imagine.

The introduction of the front-wheel braking system has not been solely responsible for the great advances made in

the effectiveness of the retarding mechanism. Brakes were considered to be a necessary evil in the old days when very crude external-contracting systems of small dimensions were employed, but the subject is now treated with greater scientific respect. Indeed, many concerns specialize in brakes and have patented designs for the shoes, drums, etc., as well as the attendant operating mechanism; under such conditions the products of the concerns in question have due to this specialization, become exceedingly efficient.

It would seem expedient, before proeeeding to deal with the subject in detail, to generalize the main points at issue. A braking system may be divided up as follows :—(a) the actual medium through which ethe .retarding action is obtained (i.e., by the frictional contacting mechanism), (b) the operating gear nud (c) the general layout for the controls. Now in a motor vehicle there' is only one reasonable manner in which a retarding effect can be obtained, i.e., through the medium of the contacting turf aces of the wheels with the ground. This means that whatever force

D.32 is applied by the driver to the -braking mechanism the resulting retarding effect must be capable of being passed through the frictional grip of the tyres on the road; in consequence, it must be less than the amount of force required to cause the wheels to lock. This factor naturally pute, a definite limit upon the retarding effect that can be exerted safely and efficiently on any individual wheel.

Carrying the argument a little farther, it will easily be

understored that the weight 'carried per wheel is an important item and one which governs, to a large execute the capacity for effective braking. Further, it will be realized that the actual grip of the tyres upon the road surface also has an important bearing upon the subject. Good brakes without good tyres are practically' useless.

Like everything else in the automobile world, progress has rim along almost parallel lines for all the components used in the make-up of a chassis ; thus, brakes arc far more

powerful than they were, but tyre grip is also much more effective. There is one incidental feature which should be mentioned here—the question of smoothness. Even suppesleg that the braking system of a modern vehicle be effective. any lack of smoothness would not be tolerated for a moment, Perfect silence in operation has not yet been achieved in all vehicles, but the root canse, of the malady of brake sheiek has been discovered and it will not be long before all up-to

date designs of braking gear are absolutely noiseless in operation under any conditions of use.

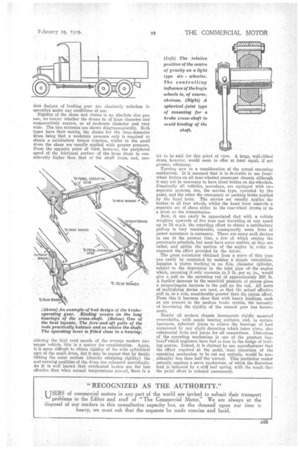

Rigidity of the shoes and drums is an absolute sine qua non, no matter whether the drums be of large diameter and comparatively narrow, or of moderate diameter and very wide. The two extremes are shown diagrammatically. Beth types have their merits, the claims for the large-diameter drum being that a moderate pressure only is required to obtain a satisfactory torque reaction, whilst in the small drum the shoes are usually applied with greater pressure. Prom the opposite point of view, however, the peripheral speed of the frictional surface of the large drum is considerably higher than that of the small drum, and, con

sideriug the high road speeds of the average modern passenger vehicle, this is a matter for eonsideration. Again, it is more difficult to obtain rigidity of the wide cylindrical part of the small drum, but it may be argued that by deeply ribbing the outer surface (thereby obtaining .rigidity) the cool-running qualities of the drum are enhanced accordingly. As it is well known that overheated brakes are far less effective than when normal temperatures prevail, there is a lot to be said for this Point of view A large, well-ribbed drum, ,however, would • seem to offer at least equal, if not greater, efficiency.

Turning now to a consideration of the actual operating mechanism. It is assumed that it is de-sirable to. use frontwheel brakes on all four-wheeled passenger chassis, although it May not be necessary to have front brakes on six-wheelers. Practically all vehicles, nowadays, are equipped with two separate systems, one, the service type, operated by the pedal, and the other the emergency or parking brake applied by the hand lever. The service set usually applies the brakes to all four wheels, whilst the hand lever controls a i separate set of shoes either to the rear-wheel drums Or to a drum on-the transmission.

Now, it can easily be appreciated that with a vehicle weighing upwards of five tons and travelling at any speed up to 50 m.p.h. the retarding effort to obtain a satisfactory pull-up is very considerable, consequently some form of power assistance is necessary. There are many such devices in use at the present time,. a few a• whiA employ the pneumatic principle, but most have servo Motors, as they are called, and utilize the suction of the engine in order to augment the .effOrt provided by the driver.

The great assistanee Obtained from a Servo of this type can easily be computed by making a .simple calculation. Iniagine a 'piston "working in an 84a.' diauleter Cylinder, subject to the depression in the fillet Pipe' of the engine which, assuming it-only amounts-bo 5 lb.• per sq. in., would give a pull on the op.erating rod of approximately 250" lb. A further, decrease in the manifold 'pressure of course gives a proportionate increase in the pull on the rod. All sorts of multiplying device are used, so that the actual effective pull is, as a rule, considerably greater than the piston effort. From this it becomes clear that with heavy loadings, such as are present in the modern brake system, the 'necessity of increasing the rigidity of the control gear has become acute.

-Nearly all modern chassis incorporate rigidly mounted cross-shafts, with ample bearing surfaces, and, in certain iustanees, spherical joints to relieve the bearings of load occasioned by any slight distortion which takes place, also substantial links and joints for all connections. Distortion of the operating mechanism is one of The greatest bugbearewhich engineers have had to face in the design of braking system. Indeed, it is claimed by one manufacturer that the effort required at the pedal, were distortion 'of the operating inechanisin to he cut out entirely, would be considerably less than halrthe normal. This particular maker actually employs h servo mechanism, of which the distortion load is balanced by a stiff leaf spring, with the result that the Pedal effort is reduced enormously.