A Remarkable Demonstration Bus.

Page 112

If you've noticed an error in this article please click here to report it so we can fix it.

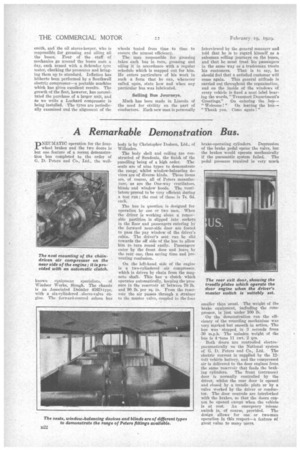

pNETTMATIO operation for the fourwheel brakes and the two doors is but one feature of a recent demonstration bus completed to the order of G. D. Peters and Co., Ltd., the well The neat mounting of the chaindriven air compressor on the near side of the engine ; it is provided with an automatic clutch. known equipment specialists, of Windsor Works, Slough. The chassis is an Associated Daimler 416D-type, witha six-cylindered sleeve-valve englueThe forward-control saloon bus

body is by Christopher Dodson, Ltd., of Willesden.

• The body shell and ceiling are constructed of Sundeala, the finish of the panelling being of a high order. The seats are of nine types to demonstrate the range; whilst window-balancing devices are of diverse kinds.. These items are, of course, all of Peters manufacture, as are the One-way Ventilators, blinds and window hoods. The ventilators .proved to be very'efficient during a test run ; the cost of these is 'Ts. 61 each.

The bus in question is designed for operation by one Or two men. When thedriver is working .alone a: removable partition is slipped into sockets in the floor and passengers entering by the forward near-side door are forced to pass the pay window of the driver's cabin. The driver's seat can be slid towards the off side of the bus to allow him to turn round easily. Passengers enter by the front door and leavq by the rear one, thus saving time and preventing confusion.

On the left-hand side of the engine is a two-eylindered air compressor, which is driven by chain from the magneto shaft. This has -a clutch which operates automatically, keeping the pressure in the reservoir at • between 70 lb. and 90 lb. per sq. in. From the reservoir the air passes through a strainer to the master valve, coupled to the four

brake-operating cylinders. Depression of the brake pedal opens the valve, but the brakes would operate mechanically

if the pneumatic system failed. The pedal pressure required is -very. much

smaller than usual. The weight of the brake equipment, including the compressor, is just under' 100 lb.

On the demonstration run the. efficiency of the retarding mechanism was very marked but smooth in action. The bus was stopped in 3 seconds from 30 m.p.h. The Unladen weight of the bus is 4 -tons 11 cwt. 2 qrs.

Both oors are controlled electiopnenmatieally on the National system of G. 0. Peters and Co., Ltd, The electric current is supplied by the 12volt vehicle battery, and the compressed air -is delivered to the door engines from the same reservoir that feeds the brak

ing cylinders. The front (entrance) door • is normally controlled by the driver, whilst the rear door is opened and closed by a, treadle plate or by a valve worked by the driver or conductor. The door controls are interlocked with the brakes, so that the doors cannot be opened except when the vehicle is at rest. An emergency r.elease switch is, of course, provided. The design allows for one or two-man operation in this respect—a feature of

great value to many users. •