How SILENCE is Being

Page 107

Page 108

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

Maintained.

The Methods Adopted by Manufacturers to Enhance the General Refinement and Smoothness of Operation of their Passenger Vehicles. Some Interesting Sidelights on Vibration and Noise.

NOISE—the exact antithesis of silence—en be regarded from two distinct points of view—with pleasure or distaste. Music, for example, although consisting substantially of a number of sounds delivered in certain sequences is nevertheless "noise," but so is the ear-splitting din which emanates from a pneumatic riveter when in operation on the hull„of a ship. In the broad sense, the first-mentioned noise', i.e., Music, is pleasant, but the latter is not. appliances are not susceptible to " magic," it is obvious that we must dig below the surface in order properly to review the matter. A little investigation of the causes of noise, therefore, may be an advantage before attempting to criticise the operation of any component used in the layout

of either the chassis or the body of a vehicle. • For the purpose of this review noise can be termed " the obtrusion of.a vibration upon one of the human senses." If that statement be fully grasped the investigation of sonnd becomes much easier. In order to obtain any obtrusion upon the ear-drums it may be taken for granted that something or other—a solid or a gas—must be set in motion and the motion must be repeated at • frequent intervals, i.e., many times per second.

Before proceeding farther it would be

as well to mention that repeated motion or vibrations (as they are termed) with a frequency of less than 30 per second, cr more than 38,000 per second, do not come within the scope of 'I+ the human ear. Take the

, noise of an electric motor,

for example. W h en

started from rest a low note is pitched by the moving parts which, as the speed increases, becomes higher and higher (due to the increase in frequency) until a point

is reached where the motor runs with apparent silence. The vibrations are still going on, but the human ear cannot detect them, due to the great rapidity with which they are repeated.

Now different people are affected by noise—remember all noises are vibrations—in different ways. Sickness is sometimes experienced due to a low rumble, which is really a vibration of. very low frequency. On the other hand, some people are given a headache (through the. medium of the ear-drums) by a noise caused by a vibration of high frequency. Consequently, in a bus chassis the designer has to eliminate so far as possible all vibrations, whether they be pitched low or high in the tonic scale. In the power-unit, for example, there are dozens of vibrations, some of which are quite beyond the scope of the human ear, but unfortunately many of them do come within normal hearing.

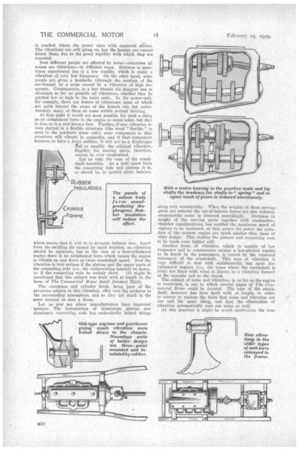

At first sight it would not seem possible for such a thing as an unbalanced force in the engine to cause noise, but that it does so is a well-known fact. Further, if any vibration be once started in a flexible structure (the word " flexible " is used in the academic sense only) some component in that structure will vibrate in sympathy, and if that component happens to have a large surface, it will act as a diaphragm gild so amplify the original vibration. Rigidity for moving parts, therefore, cannot be over emphasized.

Let us take the case of the crankshaft assembly. As a unit apart from the connecting rods and pistons it is, or should be, in perfect static balance, which means that it will be in dynamic balance also. Apart from the swirling air caused by rapid rotation, noxibration should be apparent, but in the case of a four-eylindered engine there is an unbalanced force which causes the engine to vibrate up and down at twice crankshaft speed. Now the vibration is very serious if the pistons and the upper parts of the connecting rods (i.e., the reciprocating masses) be heavy,

or if the connecting rods be unduly short. (It might be mentioned that this subject was dealt with at length in the issue of The Commercial Motor dated January 22nd).

The crankcase and cylinder block, being part of the structure subject to this vibration, offer very big surfaces to the surrounding atmosphere, and so they act much in the same manner as does ft drum.

Let us now see where manufacturers have improved . matters. The introduction of aluminium pistons and duralumin connecting rods leas undoubtedly helped things along very considerably. When the weights of these moving parts are reduced the out-of-balance forces are also reduced, consequently noise is lessened accordingly. Decrease in weight of the moving parts together with combustionchamber considerations, has enabled the maximum wed of engines to be increased, so that power for power the cylinders of the modern engine art much smaller than those of older design. This enables the pistons and connecting rods to be made even lighter still.

Another form of vibration which is usually of low frequency and in consequence creates a low-pitched rumble to be heard by the passengers, is caused by the torsional movement of the crankshaft. This type of vibration is very difficult to deal with satisfactorily, but most sixeylindered engines (i.e., the types where the crankshaft is long) are fitted with what is known as a vibration damper at the opposite end to the clutch. The subject of noise and vibration, in so far as the engine is concerned, is one to which several pages of The Commercial Motor could be devoted. The case of the crankshaft, however, has been dealt with at length, in order to convey to readers the facts that noise and vibration are one and the same thing, and that the elimination of vibration automatically cuts out noise as well.

At this juncture it might be worth mentioning the case

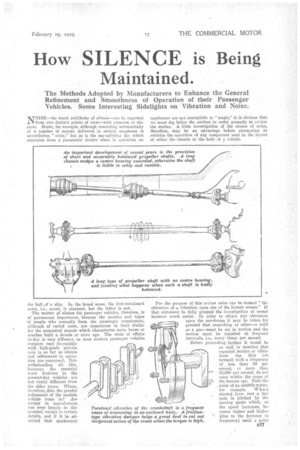

of the propeller shaft. It is, or should :be, fairly clear that a long shaft, if only very slightly out of balance, will, when revolved quickly, cause 0m enormous vibratory force to be exerted; due to the centrifugal action of the unbaianded mass: TLis, df. cciurse,"causes Vibration, which, in turn, creates a noise, and, due to its relatively low

frequenek; occasions a .rumble. In the. modern chassis designers have got over this trouble by dividing the propeller shaft and running it in two stages and, as the tendency to vibrate varies roughly as the inverse square of the lengths, matters have been enormously improved.

Returning to the engine, one cannot help noticing that valve operation is, nowadays, very much quieter thhn it used to be. This characteristic, however, does not require much investigation, because the reasons for the noise are very much more obvious. Everybody appreciates the fact that a hammer-type blow produces a noise and that continual repetition of the blows can be very disagreeable. The volume of noise, however, depends upon the rapidity with which the two objects meet each other.

In the case of the valve-operating gear, the two clashing elements, are usually the valve stem with its tappet and the valve head with its seating in the cylinder or cylinder bead. It is, of course, appreciated that rapid lift and fall for the valves are essential for a satisfactory power output from the engine, but the rate of opening during the contacting period (which probably only covers about .01 in.) can be made very gradual, the acceleration thereafter being rapidly increased up to a point where the inertia of the parts concerned forms a. limit.

The camshaft drive is often the cause of noisy running when the engine is idling, especially in the case of a fourcylindered unit. If there be backlash in the drive it will be appreciated that the cam followers, when pressed into contact alternately with the leading and trailing faces of each cam, cause a reversal of stresses in the shaft, which, in turn,. creates an oscillating tendency in the camshaft driving wheels.

Great care has been taken in recent designs to avoid this contretemps, provision having been made in the drive to

take out backlash; whilst a dummy forts-faced cam having a spring-loaded plunger in contact with its working surfaces is often .included in the layout, in order to prevent the oscillating tendency caused by the lack of continuity of force direction.

Piston slap, nowadays, does net exist in modern power inn ts, despite the fact that the aluminium piston is almost universally employed. The metallurgical expert bus helped in this matter, because alloys have been developed which, although of light weight, do not possess that annoying prone.rty of " raw " aluminium; of growing excessively when heated.. This has permitted the piston-cylinder clearances tit be cut down to a degree where just sufficient . working clearance only is required.

Looking at the question. of silence from a slightly different 'aspect, and discarding the academic side, it is clear that it is quite useless to build any component which is beautifully silent when new,but which rapidly becomes noisy with use. Wear is,' ofcourse, 'a great bugbear' 'hut . developments with lubrication systems have altered matters considerably. Take the engine, for instance.– Instnodern designs attention is paid to cooling the oil, and as the lubricating

qualities of any oil are much greater at low and medium temperatures than when very hot the advantages to be obtained from this development are very great. Indeed, one maker, the Daimler Co., claims that by using an oil radiator the lubricating qualities of the Oil have been increased by as much as 500 per cent.—a result which is highly satisfactory.

Now this, in conjunction with a copious supply of oil in circulation throughout all the bearings,, is bound to reduce wear and cause? a cushioning effect to 'take place between all contacting surfaces, resulting in a decrease in the noise which either a new or old engine would emit.

Exhaust silencing arrangements ard, generally speaking, very 'efficiently laid out, most vehicles being equipped with adequate expansion chambers and sufficiently long tail pipes, in order to guarantee that the gases are cooled by the time that they are dispersed into the, atmosphere.

We have already dealt with some phases of the transmission, but, so far, the clutch and gearbox have not been touched upon. Practically_ all up-to-date passenger chassis are equipped with single-plate clutches, in which the mountings for the free member and thewithdrawing mechanism are of a really substantial nature, which accounts for the almost entire obviation of screech..

An additional advantage of the single-disc clutch is the easy gear change afforded, due to the comparative, lightness of the driven member, which, in conjunction with ground teeth for the gearbox pinions, has made the passenger -Vehicle incomparably pleasanter.

It might be interesting to investigate the matter of gear silence there thoroughly. In certain types of gearboxes, especially those having four speeds, the main and lay shafts Ore, relatively speaking, of considerable length. When the shafts are loaded in the centre, such as When any pair of the intermediate gears is engaged, the shafts themselves curing a little. This. naturally upsets the accurate mesh of the teeth "and, if considerable, will cansesa. very Larsh whine to be einitted by the engaging teeth. This fact has, of course, been realized, and in certain of the largest gearboxes both shafts are supported at their centres. One manufacturing method employed is to project it section of one of the pinions of the gearbox on to ascreen and, under great magnification, to record the tooth contour. D19